In today’s fast-paced industrial landscape, businesses are under constant pressure to innovate, automate, and optimize. While traditional robotics has long played a key role in manufacturing and logistics, companies are now turning to custom robotic solutions—also known as bespoke robotics—to gain a competitive edge. Unlike off-the-shelf systems, bespoke robotics are designed and built specifically to meet the unique requirements of a business or production line.

From precision assembly to complex automation tasks, custom-built robotic systems are redefining what’s possible in modern manufacturing. To explore this emerging field in more depth, check out Bespoke Robotics and discover how tailored automation can transform your operations.

What Are Bespoke Robotics?

Bespoke robotics refers to the design, development, and implementation of tailor-made robotic systems built for specific applications. Instead of relying on pre-configured robots that may only meet part of a company’s needs, bespoke solutions are engineered to perform tasks with precision and efficiency that generic systems can’t match.

These robots are developed through close collaboration between engineers and clients, ensuring that every aspect—hardware, software, and control systems—aligns perfectly with the desired outcome. Whether it’s an automated assembly line, precision welding robot, or a collaborative cobot working alongside humans, bespoke robotics brings a new level of customization to industrial automation.

Why Customization Matters in Modern Industry

Every industry faces unique challenges. Automotive manufacturers, for instance, demand precision and speed, while pharmaceutical companies require cleanliness, safety, and traceability. Off-the-shelf robotic systems may provide partial solutions but often lack the flexibility to adapt to specific production environments.

This is where bespoke robotics stands out. Tailored systems can be built to handle intricate tasks, integrate seamlessly with existing machinery, and scale as business needs evolve. In short, custom robotic solutions give companies the flexibility to innovate without compromise.

The Advantages of Bespoke Robotics Solutions

Implementing bespoke robotic systems provides a wide range of benefits that go far beyond simple automation. Here’s how they’re reshaping industries:

1. Increased Efficiency and Productivity

Custom robots are designed for a specific workflow, which means they perform tasks faster and more accurately than human workers or generic systems. This leads to higher throughput and reduced cycle times.

2. Enhanced Precision and Quality

Bespoke systems are engineered to maintain consistency in repetitive tasks. They minimize human error and ensure every product meets exacting quality standards.

3. Scalability and Flexibility

Unlike rigid, one-size-fits-all robots, bespoke solutions can be reprogrammed, upgraded, or retooled as production requirements change—making them future-proof investments.

4. Cost-Effective in the Long Run

Although the initial cost of a custom robot may be higher, the long-term savings in labor, material waste, and downtime often deliver a faster return on investment.

5. Seamless Integration

Bespoke robotics can be designed to fit into existing production lines, making the transition to automation smooth and non-disruptive.

These advantages make bespoke robotics the go-to choice for industries striving for precision, adaptability, and sustainability.

Industries That Benefit from Bespoke Robotics

The potential applications of bespoke robotic systems span virtually every industrial sector. Here are some industries reaping the most rewards:

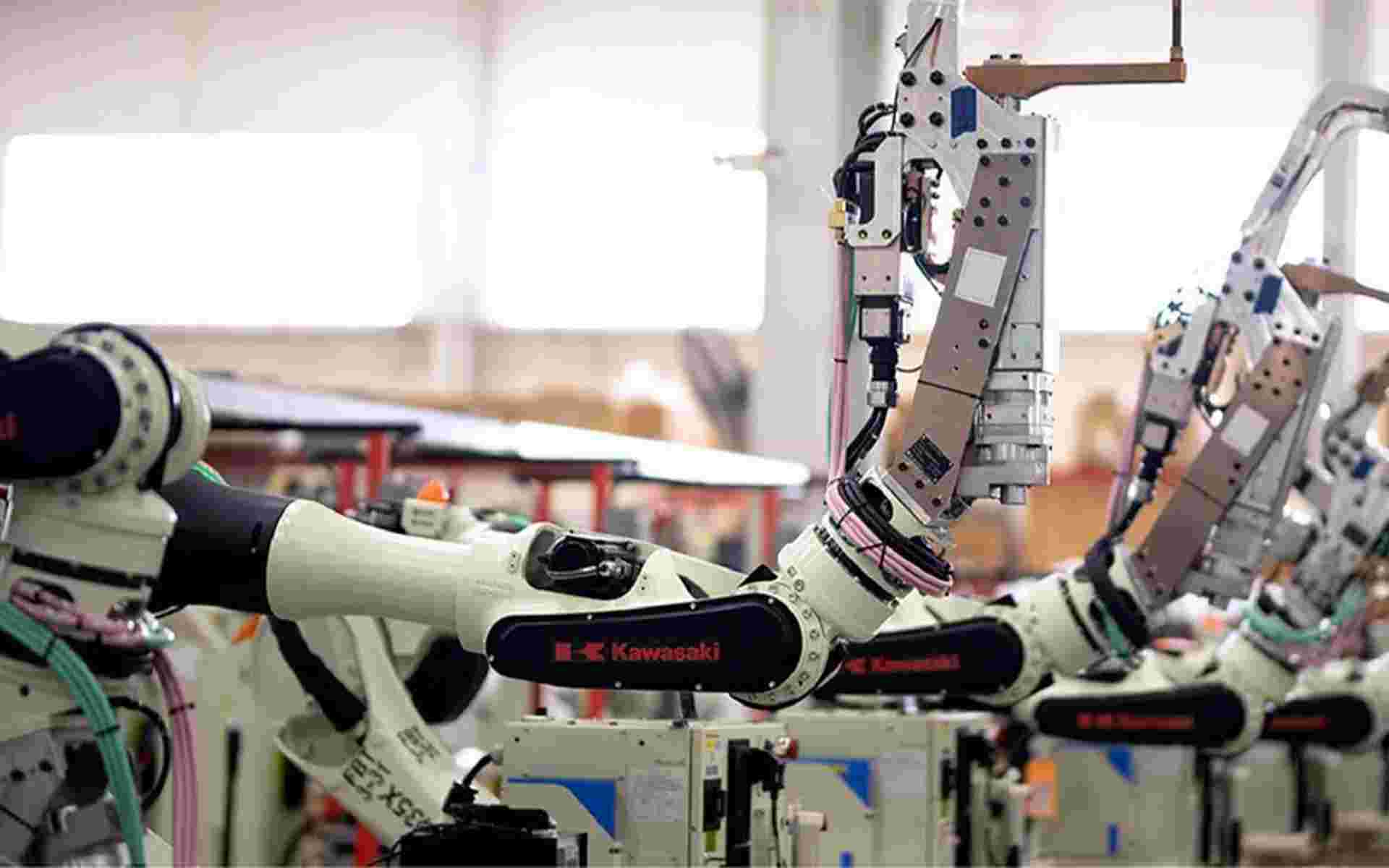

Manufacturing

Custom robotics streamline assembly lines, handle repetitive tasks, and maintain precision in complex operations such as welding or component fitting.

Aerospace

In aerospace, bespoke robots assist with delicate operations like drilling, riveting, and material handling, where accuracy and safety are paramount.

Pharmaceutical and Medical

Automation in these sectors improves hygiene, accuracy, and compliance with strict regulatory standards. Robots can handle delicate packaging and inspection tasks with unmatched precision.

Automotive

Bespoke robotic systems are a mainstay in automotive production, managing processes such as painting, welding, and part assembly with speed and accuracy.

Food and Beverage

Custom automation ensures safe, hygienic, and efficient food processing, packaging, and labeling, minimizing human contact and contamination risks.

Across these industries, custom robotic solutions are driving efficiency while maintaining quality and compliance.

Designing a Bespoke Robotic Solution

Developing a bespoke robotic system involves a detailed, collaborative process that ensures every element aligns with the client’s objectives. Here’s a simplified overview of how it works:

-

Consultation and Needs Assessment: Engineers assess the client’s workflow, pain points, and goals.

-

Concept Design: Using 3D modeling and simulation tools, designers create a virtual prototype of the robotic system.

-

Development and Testing: The robot is built, programmed, and tested to ensure it performs flawlessly under real-world conditions.

-

Installation and Integration: Once approved, the robot is installed and seamlessly integrated into the client’s production line.

-

Ongoing Support and Maintenance: Continuous technical support ensures the system remains efficient and up to date.

This end-to-end approach ensures that each bespoke system delivers measurable improvements in performance and reliability.

The Role of Artificial Intelligence in Bespoke Robotics

AI and machine learning are taking bespoke robotics to the next level. Smart robots can now analyze data, adapt to environmental changes, and even make autonomous decisions.

For example, an AI-powered robotic arm can detect variations in a product’s shape and automatically adjust its grip or positioning. Machine learning algorithms also help predict maintenance needs, reducing downtime and extending the robot’s lifespan.

Integrating AI into bespoke robotics creates systems that are not only efficient but also intelligent—capable of learning and improving over time.

Collaborative Robots: The Human-Robot Partnership

One of the most exciting advancements in bespoke robotics is the rise of collaborative robots, or “cobots.” Unlike traditional robots that operate behind safety barriers, cobots are designed to work safely alongside humans.

They handle repetitive or physically demanding tasks while allowing human workers to focus on problem-solving and quality control. This collaboration enhances productivity, safety, and job satisfaction.

Bespoke cobots can be customized to perform highly specific functions within a shared workspace, offering a perfect balance between automation and human creativity.

Sustainability and Efficiency in Custom Robotics

Sustainability is becoming a major priority for modern industries, and bespoke robotics plays a key role in achieving it. Custom robotic systems reduce waste by ensuring precise material usage, optimizing energy consumption, and minimizing errors that lead to rework.

They can also be programmed to operate during off-peak hours, lowering energy costs. As industries strive toward greener practices, bespoke automation stands as a sustainable, forward-thinking solution.

Challenges in Implementing Bespoke Robotics

Despite the many advantages, adopting bespoke robotics comes with challenges. Some of the most common include:

-

Initial investment costs: Developing a custom robot requires upfront design and engineering expenses.

-

Technical expertise: Operators and engineers need proper training to maintain and program the system.

-

Integration complexity: Custom systems must be carefully integrated with existing equipment and software.

However, with proper planning and collaboration with experienced providers, these challenges can be easily overcome. The long-term benefits far outweigh the initial hurdles.

For businesses considering implementation, consulting specialists in Bespoke Robotics can ensure a seamless transition from concept to deployment.

The Future of Bespoke Robotics

The future of bespoke robotics lies in flexibility, intelligence, and human collaboration. Emerging technologies like AI, IoT, and digital twins will continue to enhance customization and adaptability.

We’ll see more robots capable of self-optimization, predictive maintenance, and real-time communication with other machines. As industries evolve, custom robotic solutions will play a vital role in driving productivity, safety, and sustainability.

Bespoke robotics won’t just automate tasks—it will redefine how businesses design, build, and innovate.

Conclusion: Embracing the Future with Bespoke Robotics

In a world where every industry demands greater efficiency and precision, bespoke robotics offers the ultimate solution. By tailoring automation to specific needs, businesses can achieve new levels of performance, adaptability, and innovation.

Whether it’s improving safety, reducing waste, or optimizing workflow, custom robotic solutions represent the future of industrial progress.