Monolithic casting is revolutionizing the construction industry by enabling the creation of robust and seamless structures in a single concrete pour. This method ensures durability, reduces construction time, and enhances structural integrity. Builders and engineers increasingly rely on monolithic casting to achieve high-quality results, especially for residential, commercial, and industrial projects.

Understanding Monolithic Casting

Monolithic casting involves pouring concrete continuously into a mold or formwork, creating a unified structure without joints. This technique eliminates weak points typically found in conventional construction methods and improves the load-bearing capacity of the building.

Key benefits of monolithic casting include:

-

Enhanced Strength: Seamless structures withstand higher stress and environmental conditions.

-

Time Efficiency: Eliminates multiple casting cycles, speeding up project completion.

-

Cost-Effective: Reduces labor and material wastage associated with traditional construction methods.

-

Aesthetic Finish: Smooth and uniform surfaces require minimal finishing work.

Applications of Monolithic Casting

Monolithic casting is widely applied in various construction scenarios, such as:

-

Residential Buildings: Ensures sturdy walls, floors, and columns with minimal joints.

-

Commercial Complexes: Ideal for high-rise structures due to consistent strength across floors.

-

Industrial Facilities: Suitable for heavy-duty floors and storage units needing uniform load distribution.

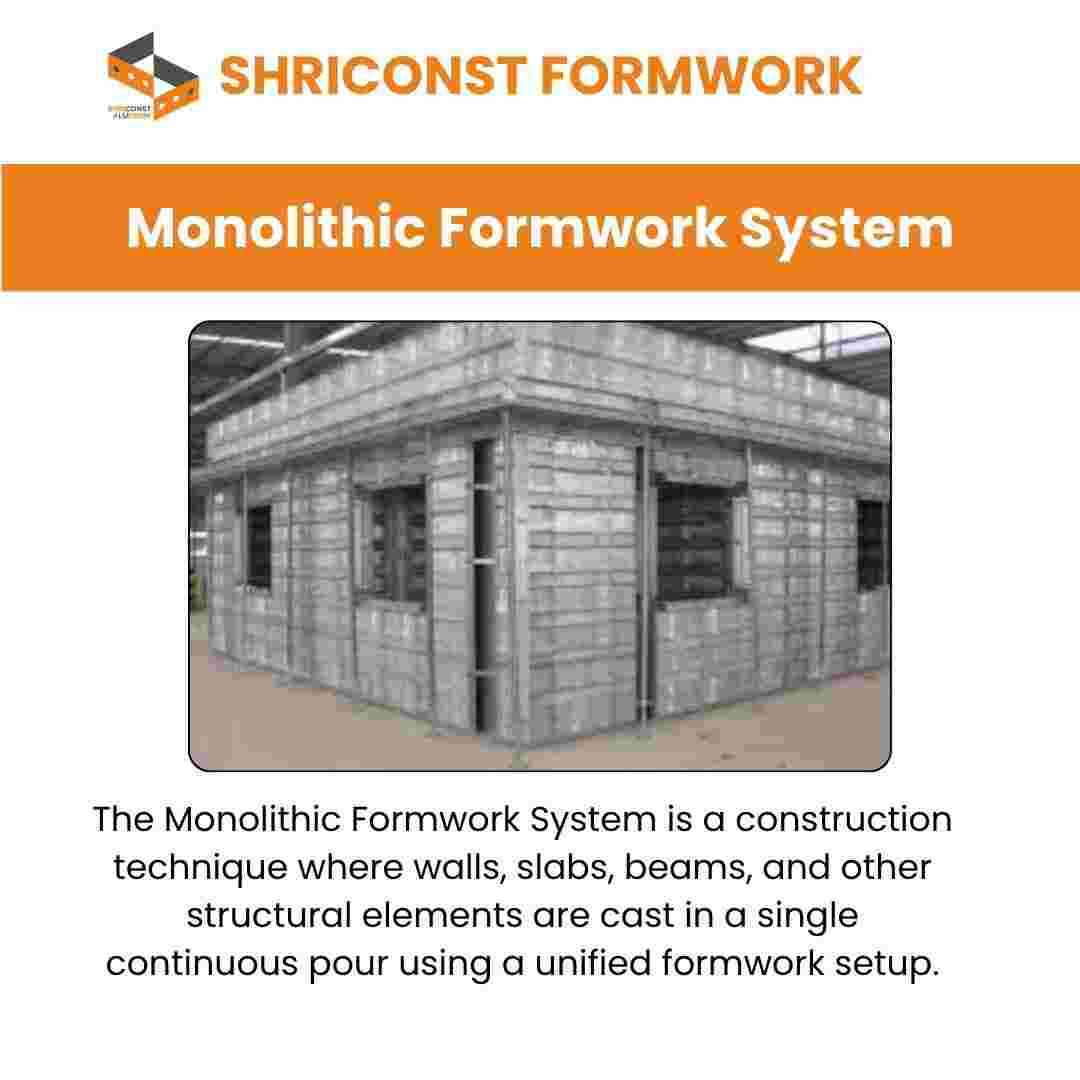

Role of Formwork in Monolithic Casting

Formwork plays a crucial role in shaping and supporting concrete until it sets. Using high-quality formwork ensures the accuracy, safety, and efficiency of monolithic casting operations. Businesses looking for reliable solutions often consult top formwork manufacturers in India for durable and adaptable systems.

Why Choose Monolithic Casting

The method offers multiple advantages over traditional construction techniques:

-

Reduced Labor Requirements – Fewer skilled workers are needed due to the simplified process.

-

Minimal Joint Maintenance – Absence of joints reduces long-term maintenance concerns.

-

Environmental Benefits – Less waste and energy usage contribute to sustainable construction practices.

-

Structural Stability – Continuous casting reduces the likelihood of cracks and weak zones.

Conclusion

Monolithic casting has become a preferred choice for modern construction projects due to its strength, efficiency, and cost-effectiveness. By combining advanced formwork systems with skilled engineering, builders can achieve structures that are durable, aesthetically appealing, and built faster. Partnering with trusted companies like Shriconst Aluform ensures access to top-quality solutions for all monolithic casting needs.