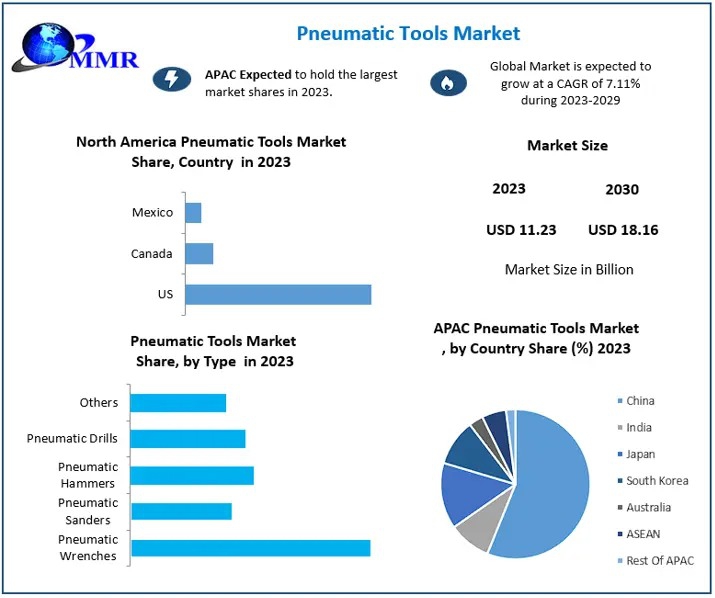

The Pneumatic Tools Market Trends was valued at approximately $11.23 billion in 2023 and is projected to reach $18.16 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 7.11% during the forecast period.

Pneumatic tools, also known as air tools, are powered by compressed air supplied by air compressors. These tools are widely used across various industries, including automotive, construction, manufacturing, and aerospace, due to their durability, efficiency, and ability to perform heavy-duty tasks without the risk of electric hazards.

Click here for free sample + related graphs of the report @ https://www.maximizemarketresearch.com/request-sample/87634/

Market Growth Drivers & Opportunities

Several factors are contributing to the robust growth of the pneumatic tools market:

-

Industrial Expansion: The surge in automotive, construction, and manufacturing activities has driven the demand for pneumatic tools in both developed and developing countries. These tools are preferred for their ability to handle rigorous tasks, enhancing productivity and operational efficiency.

-

Technological Advancements: Innovations in pneumatic technology have led to the development of more efficient and user-friendly tools. Features such as ergonomic designs, reduced noise levels, and enhanced safety mechanisms are attracting a broader user base.

-

Safety and Maintenance Benefits: Unlike electric tools, pneumatic tools lack a motor, mitigating risks of overload and overheating, while requiring minimal maintenance. This makes them a cost-effective and safer option for various industrial applications.

-

Environmental Considerations: Pneumatic tools are often more environmentally friendly compared to their electric counterparts, as they do not rely on batteries and have a longer lifespan, reducing waste and the need for frequent replacements.

Segmentation Analysis

The pneumatic tools market is segmented based on tool type, application, end-use industry, and region:

-

By Tool Type:

- Wrenches: Used extensively in automotive and manufacturing sectors for tightening and loosening bolts and nuts.

- Sanders & Polishers: Employed in woodworking, automotive, and metalworking industries for surface finishing tasks.

- Drills: Utilized across various industries for drilling holes in materials like wood, metal, and concrete.

- Grinders: Commonly used for cutting, grinding, and polishing applications in metalworking and construction.

- Others: Includes nailers, staplers, and screwdrivers, serving diverse applications across multiple industries.

-

By Application:

- Industrial: Pneumatic tools are integral in manufacturing processes, assembly lines, and maintenance operations due to their reliability and efficiency.

- Automotive: Widely used in vehicle assembly, repair, and maintenance tasks, enhancing precision and reducing labor time.

- Construction: Essential for tasks such as drilling, nailing, and sanding, contributing to faster project completion and improved safety.

- Others: Includes applications in sectors like aerospace, shipbuilding, and agriculture, where specialized pneumatic tools are utilized.

-

By End-Use Industry:

- Manufacturing: The largest consumer of pneumatic tools, employing them in various production and maintenance activities.

- Automotive: Utilizes pneumatic tools extensively in assembly lines and repair shops for efficiency and precision.

- Construction: Relies on pneumatic tools for tasks like framing, roofing, and finishing, enhancing productivity and safety.

- Others: Encompasses industries such as aerospace, mining, and oil & gas, where pneumatic tools are used in specialized operations.

Click here for free sample + related graphs of the report @ https://www.maximizemarketresearch.com/request-sample/87634/

Competitive Analysis

The pneumatic tools market is highly competitive, with key players focusing on innovation, quality, and strategic partnerships to maintain their market positions. Notable companies include:

-

Atlas Copco: A leading provider of industrial tools and equipment, offering a wide range of pneumatic tools known for their durability and performance.

-

Ingersoll Rand: Renowned for its innovative pneumatic tools designed for various industrial applications, emphasizing efficiency and user comfort.

-

Makita Corporation: Offers a comprehensive range of pneumatic tools, focusing on ergonomic designs and advanced features to enhance user experience.

-

Stanley Black & Decker: Provides high-quality pneumatic tools catering to both professional and DIY markets, known for their reliability and affordability.

-

Hitachi Koki Co., Ltd.: Specializes in professional-grade pneumatic tools, serving industries like construction and manufacturing with a focus on innovation and safety.

Country-Level Analysis

-

United States: The U.S. pneumatic tools market is experiencing steady growth, driven by advancements in manufacturing and construction sectors. The emphasis on infrastructure development and technological innovation is fostering increased adoption of pneumatic tools.

-

Germany: As a leading industrial nation, Germany's demand for pneumatic tools is bolstered by its robust automotive and manufacturing industries. The focus on precision engineering and high-quality production processes contributes to the market's expansion.

-

China: Rapid industrialization and urbanization in China have led to a substantial increase in construction and manufacturing activities, driving the demand for pneumatic tools. Government initiatives promoting infrastructure development further support market growth.

-

India: The growing automotive industry and infrastructure projects in India are fueling the demand for pneumatic tools. The push for 'Make in India' and the development of smart cities are expected to provide significant growth opportunities.

Conclusion

The pneumatic tools market is on a robust growth trajectory, driven by industrial expansion, technological advancements, and the increasing demand for efficient and reliable tools across various sectors.