The aerospace industry is undergoing a major metamorphosis, with robotics being a game-changer for improving manufacturing, maintenance, and operational efficiencies. With the need for precision, safety, and cost-effectiveness on the rise, aerospace robotics becomes a key driver of these goals.

Key Drivers of Market Growth

1. Automation for Improved Precision and Efficiency

Robotics are becoming widely used in aerospace production to drill, weld, paint, and assemble with precision. Automation not only enhances the quality of products but also minimizes production time and cost, which fulfills the requirement of the industry to be efficient and consistent.

2. Integration of Advanced Technologies

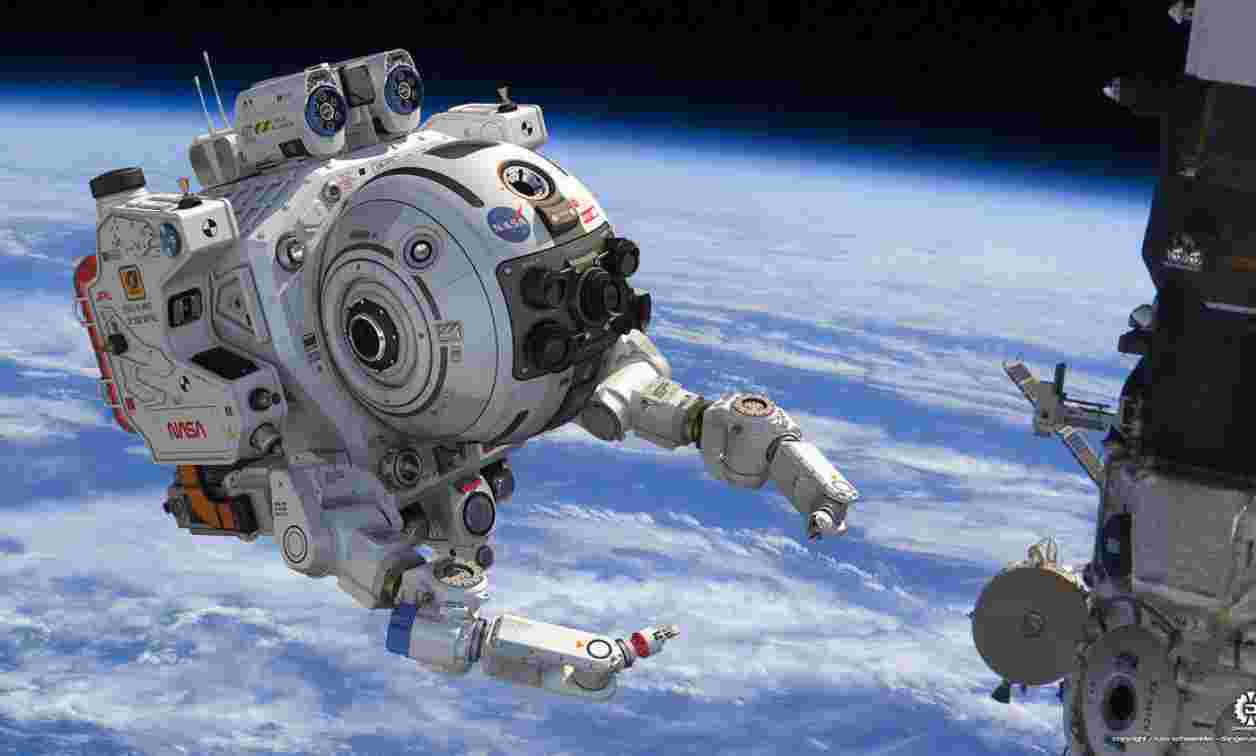

The integration of Artificial Intelligence (AI), Machine Learning (ML), and the Internet of Things (IoT) into robotics systems provides predictive maintenance, adaptive control, and real-time data analysis. These technologies make intelligent decision-making possible and improve overall aerospace operation performance.

3. Collaborative Robotics (Cobots)

The use of collaborative robots, or cobots, provides room for efficient and safe human-robot interaction. In aerospace environments, cobots support human operators in tasks needing precision and reproducibility and thus enhancing productivity and mitigating the occurrence of human error.

4. Focus on Sustainability

Robotics plays a role in environmentally sustainable manufacturing practices by optimizing energy usage, reducing material wastage, and promoting the use of environmental-friendly materials. This corresponds with the objectives of the aerospace industry to minimize its environmental impact.

Market Segmentation

By Type

· Articulated

· Cartesian

· Cylindrical

· SCADA

By Technology

· Traditional

· Collaborative

By Application

· Drilling

· Welding

· Painting and Coating

· Inspection

Key Players

· ABB Ltd.

· FANUC

· Kawasaki Heavy Industries, Ltd.

· Universal Robots

· Infosys

· JR Automation

· Agile Robots

· Maxar Technologies

· Reliable Robotics

Geography

· North America

· Europe

· Asia-Pacific

· South and Central America

· Middle East and Africa

Challenges Facing the Market

1. High Initial Investment

Advanced robotics systems require heavy capital investment, including the robots themselves, integration, and training. The heavy initial investment may be a limitation, particularly for small to medium-sized enterprises.

2. Shortage of Skilled Workforce

Complex robotics systems need to be operated and serviced by skilled people. The impending shortage of trained technicians is a limiting factor in the far-reaching implementation of robotics in the aerospace industry.

3. Technical Integration Complications

Integrating robots into current aerospace systems may technically be difficult and require careful planning and implementation for compatibility and proper performance.

Conclusion

Aerospace robotics is changing the industry by bringing in automation, precision, and efficiency to manufacturing and maintenance processes. Despite problems like high setup costs and a lack of skilled workers, advantages such as improvements in productivity and sustainability brought about by using robotics are very attractive. With technology ongoing, use of robotics in aerospace is likely to become more prevalent, leading to innovation and competition in the industry.