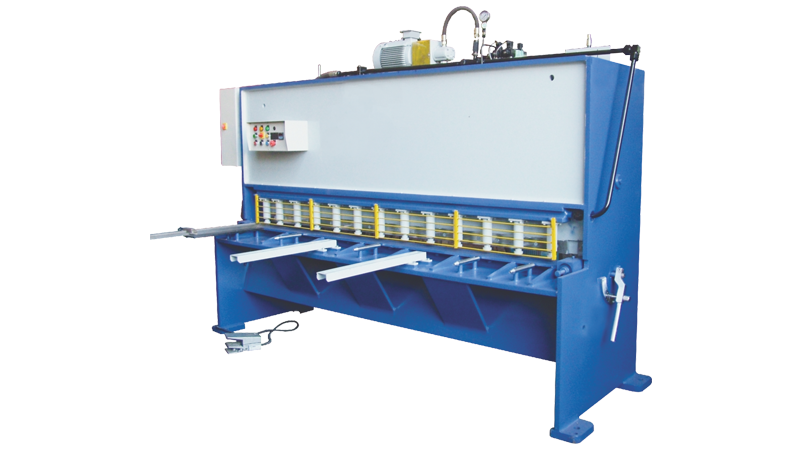

In today’s competitive manufacturing landscape, investing in high-quality machinery is a necessity rather than a luxury. Among the most critical tools used in the metalworking and fabrication industry are shearing machines, designed to precisely cut sheet metals without the formation of chips or the use of burning or melting. To ensure maximum productivity and minimal downtime, choosing the right Shearing Machine Manufacturers is essential.

This comprehensive guide explores the key considerations when selecting Shearing Machine Manufacturers and why it’s beneficial to work with manufacturers who also excel as Slotting Machine Manufacturers.

Why the Right Shearing Machine Matters

Shearing machines serve as the backbone of several industrial processes. Whether you are working in automotive, construction, shipbuilding, or metal fabrication, a reliable shearing machine offers:

- High-speed cutting operations

- Precise edge finishes

- Increased production efficiency

- Reduced material waste

Given the machine's importance, selecting trustworthy Shearing Machine Manufacturers ensures not only the performance but also the longevity of your equipment.

Key Qualities of Reliable Shearing Machine Manufacturers

1. Experience and Industry Reputation

When assessing Shearing Machine Manufacturers, one of the first indicators of reliability is their industry experience. A longstanding company with decades of expertise often indicates:

- Strong industry knowledge

- A wide client base

- Proven track record of product performance

You can also cross-check their reputation through customer testimonials, online reviews, and case studies. Additionally, manufacturers who also have a solid background as Slotting Machine Manufacturers often bring additional expertise in metal shaping and processing technologies.

2. Quality of Materials and Build

The performance of a shearing machine is heavily influenced by the quality of its construction. Reputable Shearing Machine Manufacturers use high-grade steel, precision-engineered components, and wear-resistant cutting blades.

Look for signs that the manufacturer adheres to:

- ISO and other quality certifications

- Strict material sourcing policies

- Regular quality testing procedures

If the manufacturer also builds slotting machines, this often indicates a broader commitment to quality, as Slotting Machine Manufacturers must also maintain tight mechanical tolerances in their products.

Customization Options and Technical Support

1. Tailored Solutions to Fit Your Needs

Different businesses have different shearing requirements. A manufacturer’s ability to offer custom-built machines is a strong indicator of their expertise and customer-centric approach.

When evaluating Shearing Machine Manufacturers, check whether they:

- Offer hydraulic or mechanical shearing options

- Provide machine models suitable for your material thickness

- Design solutions tailored for small-scale or mass production

Companies that also act as Slotting Machine Manufacturers usually have a better grasp of how various tools interact in the production line, offering seamless integration across machinery.

2. After-Sales Support and Maintenance

Top-tier Shearing Machine Manufacturers provide extensive after-sales support, including:

- Installation assistance

- Regular maintenance services

- Easy availability of spare parts

- Training sessions for operators

Similarly, experienced Slotting Machine Manufacturers understand the need for ongoing support to ensure consistent performance, making them more reliable partners overall.

Technological Advancements and Compliance

1. Use of Modern Technology

Modern-day shearing machines are equipped with:

- CNC systems for precision control

- Digital displays for ease of operation

- Energy-efficient motors

Reliable Shearing Machine Manufacturers invest in R&D to integrate the latest technological innovations into their products. If a manufacturer also produces advanced slotting machines, it’s a good sign they are keeping up with industry trends. The top Slotting Machine Manufacturers often apply similar technological upgrades to all their machinery lines, ensuring uniformity and reliability.

2. Regulatory Compliance and Safety Standards

Manufacturers should adhere to both national and international safety and quality regulations. This includes:

- CE certifications

- OSHA compliance

- In-built safety features like overload protection and emergency stop

Top Shearing Machine Manufacturers typically align their production processes with global standards. Companies recognized as Slotting Machine Manufacturers also usually uphold the same safety benchmarks across their range of products.

Cost Considerations and ROI

1. Competitive Pricing with Value for Money

While price should not be the sole deciding factor, it’s essential to balance cost with quality. Trusted Shearing Machine Manufacturers provide detailed cost breakdowns and offer machines that justify their price through durability and efficiency.

Manufacturers who also specialize as Slotting Machine Manufacturers often offer bundle deals or integrated solutions, reducing overall setup costs for clients and improving ROI.

2. Warranty and Long-Term Investment

Never overlook the importance of warranty. A longer warranty indicates the manufacturer’s confidence in their product quality.

Key warranty inclusions to look for:

- Coverage for mechanical failure

- Free service visits for a specific period

- Access to OEM spare parts

Manufacturers who are also Slotting Machine Manufacturers tend to offer comprehensive warranties across their product range, helping you safeguard your investment.

Final Thoughts

Choosing the right Shearing Machine Manufacturers can significantly influence your production efficiency, machine lifespan, and overall operational costs. From quality assurance and customization to after-sales service and pricing, every aspect plays a crucial role in long-term satisfaction.

Additionally, manufacturers who also have a footprint as Slotting Machine Manufacturers bring added versatility and expertise, which often translates into better product design, functionality, and service.

By considering the above factors, you not only invest in the right machinery but also align your business with a manufacturing partner that supports your long-term goals.