In the world of plastic injection molding, offer a strategic way to improve product performance, aesthetics, and end-user comfort by bonding two or more materials into a single component.

What Are Overmoulding Services?

Overmoulding services is a multi-shot injection molding process where a base component—usually made from a rigid plastic or metal—is molded first, and then a secondary material, typically a softer thermoplastic elastomer (TPE), is molded over it. This creates a multi-material part without needing adhesives or mechanical fasteners.

Unlike traditional molding processes, overmoulding enhances functionality and user experience in a single production cycle.

The Overmoulding Process: Step-by-Step

Step 1: Base Component Molding

A rigid plastic (or metal) substrate is molded or pre-formed.

Step 2: Insert Placement

The pre-molded part is transferred to a second mold cavity or machine.

Step 3: Overmoulding

A softer material is injected to encapsulate or cover specific areas of the base component.

Step 4: Cooling and Ejection

After proper cooling, the finished two-material component is ejected from the mold.

This efficient process helps reduce assembly time and minimizes part defects caused by adhesives or misalignment.

Materials Commonly Used in Overmoulding

Choosing the right material pair is critical for ensuring proper adhesion and durability. Some popular material combinations include:

-

ABS + TPE

-

Polycarbonate + Silicone

-

Nylon + Santoprene

-

Aluminum + Rubberized Overmould

Proper adhesion depends on chemical compatibility, surface energy, and molding temperature settings.

Benefits of Overmoulding Services

Enhanced Grip and Ergonomics

Soft-touch surfaces provide comfort and reduce slippage in tools, handles, and electronics.

Improved Aesthetics

Multi-color or textured finishes can be added directly to the part for better branding and appeal.

Sealing and Waterproofing

Overmoulded layers help seal electrical components and prevent moisture ingress.

Vibration and Shock Absorption

The soft outer layer dampens vibrations in electronic housings and automotive parts.

Reduced Assembly

Combining multiple materials in one mold reduces time, cost, and part count in production.

These advantages are why many industries prefer overmoulding over manual assemblies or post-molding operations.

Applications Across Industries

Overmoulding is a versatile solution used in many demanding sectors:

Consumer Electronics

Phone grips, charging cables, and controller housings with soft, grippy surfaces.

Medical Devices

Syringe plungers, surgical tools, and sealed device housings that require biocompatibility and grip.

Automotive Components

Dashboards, knobs, switches, and connectors designed for durability and tactile feedback.

Industrial Equipment

Power tool housings and machine grips that require shock resistance and safety.

Household Goods

Toothbrushes, kitchen tools, and razors benefit from water resistance and soft ergonomics.

Each application demands precise engineering to ensure material compatibility and longevity.

Key Design Considerations for Overmoulding

To ensure success in overmoulding, engineers should follow these design principles:

-

Include Undercuts or Holes: Helps mechanical interlocking between the base and overmould.

-

Draft Angles: Make ejection easier without damaging the part.

-

Uniform Wall Thickness: Avoids warping or sink marks.

-

Material Pairing: Choose materials with compatible melt and bonding properties.

-

Avoid Sharp Corners: Encourages smooth flow of molten plastic.

Designing for overmoulding early in the product development cycle can reduce tool revisions and lead times.

Types of Overmoulding Techniques

Different methods are used depending on part complexity and volume:

Two-Shot Molding

Performed on specialized machines, both base and overmould are formed in one continuous process.

Insert Molding

A pre-formed part (plastic or metal) is placed in a mold and overmoulded in one shot.

Multiple Injection Molding

Used for parts requiring more than two materials. Common in complex electronics or medical assemblies.

Each method has its cost, speed, and precision trade-offs.

Differences Between Overmoulding and Insert Molding

| Feature | Overmoulding | Insert Molding |

|---|---|---|

| Process | Two-stage (or two-shot) molding | Single-stage molding with insert |

| Material Use | Combines soft and rigid plastics | Often includes metal inserts |

| Main Benefit | Ergonomics, sealing | Strength, electrical conductivity |

| Complexity | Higher | Moderate |

Though related, each technique serves different end-use goals and performance requirements.

Quality Control in Overmoulding

Maintaining part quality during overmoulding requires strict checks:

-

Bond Integrity Testing: Pull or peel tests ensure the layers stay joined.

-

Visual Inspection: Confirms correct coverage and surface finish.

-

Dimensional Verification: Ensures shrinkage or warping hasn't affected tolerances.

-

Material Certification: Validates chemical and mechanical properties for safety and compliance.

Well-documented QC processes reduce waste and customer rejections.

Environmental Considerations

With growing emphasis on sustainability, overmoulding also contributes to:

-

Material Efficiency: Reduces use of secondary adhesives or fasteners.

-

Durability: Longer product life leads to less frequent replacement.

-

Recyclability: Many compatible material combinations are recyclable together.

-

Energy Savings: One integrated process saves power over multiple assembly steps.

These factors make overmoulding a viable solution in eco-conscious product design.

Cost Factors in Overmoulding Services

Cost will vary based on multiple elements:

-

Tooling Complexity: Multi-material molds are more intricate and costly.

-

Material Selection: Specialized elastomers or medical-grade plastics cost more.

-

Volume: High-volume orders reduce per-unit cost significantly.

-

Machine Type: Two-shot machines are more efficient but require capital investment.

Discussing requirements early with your service provider helps align expectations and optimize pricing.

Choosing the Right Overmoulding Partner

When selecting a manufacturing partner for overmoulding services, consider:

-

Technical Expertise: Look for experience with your specific material combinations and applications.

-

Tooling Capabilities: Can they support multi-cavity or family mold designs?

-

Quality Certifications: ISO 9001 or ISO 13485 for medical-grade components.

-

Lead Time and Flexibility: How responsive is the supplier during design iterations?

-

In-House Engineering: Support for DFM (Design for Manufacturing) and prototyping.

The right partner can make a significant impact on product quality and speed to market.

Future Trends in Overmoulding Services

As demand for compact, multi-functional parts rises, overmoulding continues to evolve:

Smart Material Overmoulding

Incorporation of sensors or flexible electronics into overmoulded parts.

Multi-Layer Molding

Adding three or more distinct layers for advanced functionality and aesthetics.

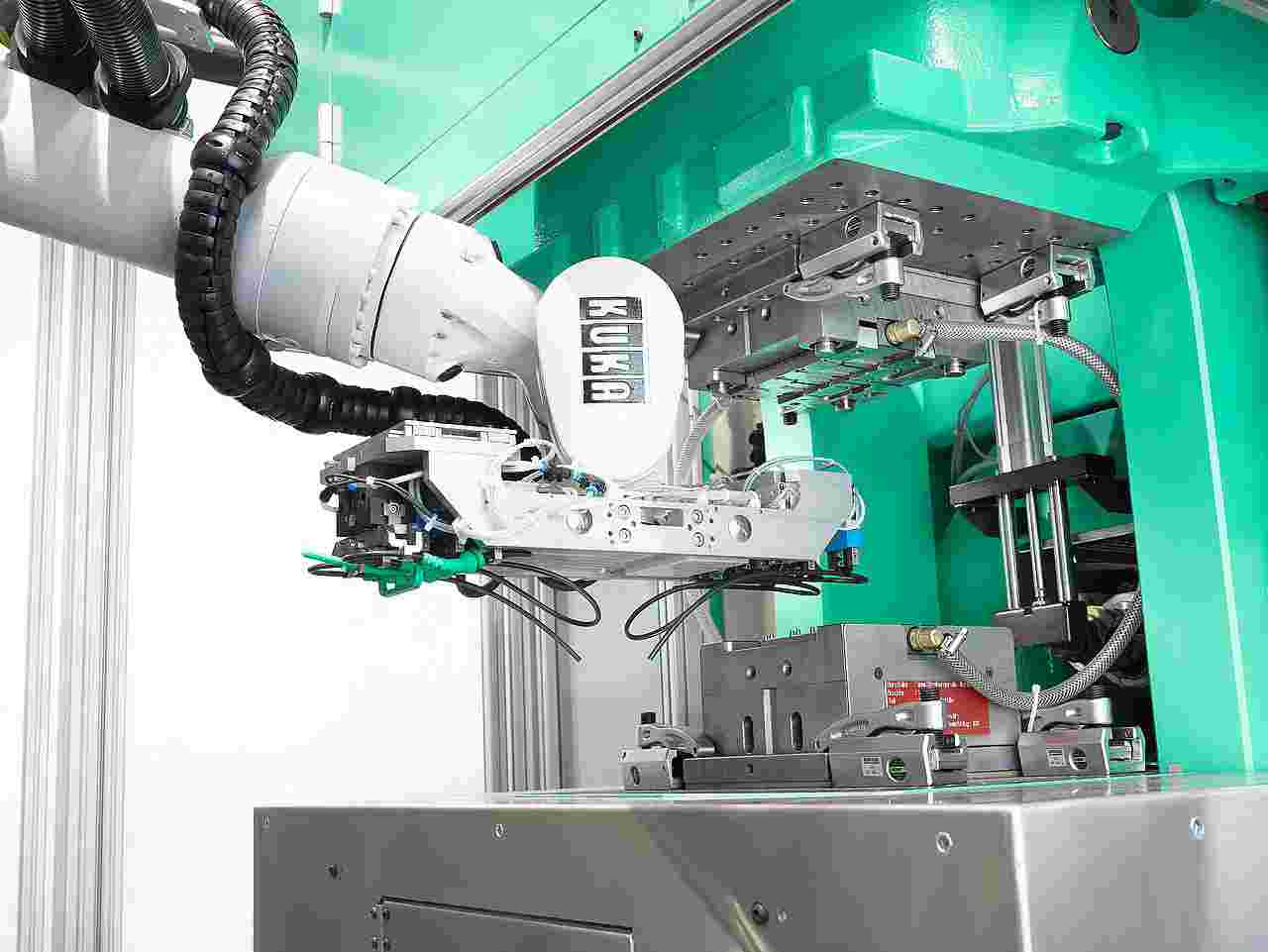

Automation and Robotics

Fully automated part transfer and inspection systems to reduce labor costs and boost consistency.

Sustainable Overmoulding

Use of bio-based polymers and recyclable materials to meet environmental regulations.

Keeping pace with these trends ensures competitiveness and compliance in the future.

Final Thoughts

Overmoulding services are essential in today’s manufacturing ecosystem, offering high-quality, functional parts that combine multiple materials in a seamless process. From consumer products to industrial machinery, the benefits of overmoulding—like reduced assembly, improved aesthetics, and enhanced performance—make it a valuable solution for both high-volume production and specialized applications.