Plastic components are everywhere—from automotive dashboards to medical device housings, from packaging prototypes to electronic casings. Achieving consistent, high-quality plastic parts requires tools capable of precise, repeatable manufacturing. One of the most efficient technologies for this task is the cnc machine for plastic. This article will provide a complete, SEO-optimized guide to CNC machining for plastic materials, detailing processes, machine selection, material compatibility, and more.

What Is CNC Plastic Machining?

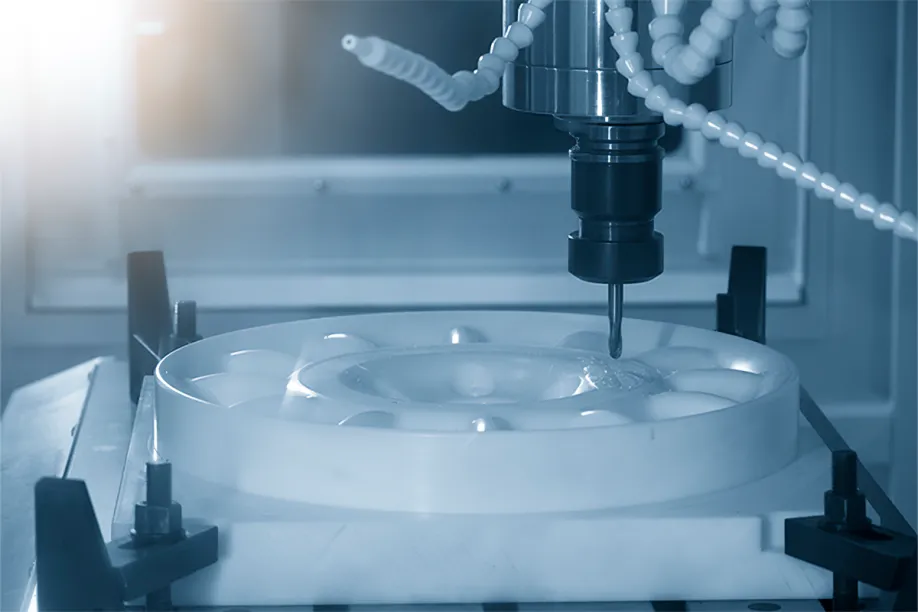

CNC (Computer Numerical Control) plastic machining refers to the automated process of cutting, drilling, and shaping plastic workpieces using pre-programmed software and high-precision tools. It replaces manual operations with computer-aided control, allowing for repeatable, complex part geometries with extremely tight tolerances.

Unlike traditional methods like injection molding, CNC machining is ideal for small to medium production runs, prototypes, or when dimensional accuracy is non-negotiable. CNC machines used for plastics are designed or adjusted to handle the material’s lower melting points and different friction characteristics compared to metals.

Benefits of Using CNC Machines for Plastic Parts

CNC plastic machining delivers numerous advantages across industries:

-

High Precision: Achieve tolerances as tight as ±0.001 inches, critical in aerospace, medical, and electronics.

-

Repeatability: Produces identical parts even across multiple batches.

-

Material Variety: Compatible with many plastic types including ABS, Nylon, PTFE, Polycarbonate, PEEK, and more.

-

No Tooling Required: Unlike molding, there's no need for custom molds, reducing lead times.

-

Fast Turnaround: Perfect for rapid prototyping or low-volume production.

-

Superior Surface Finish: Produces smooth surfaces ready for use or assembly.

Key Plastic Materials for CNC Machining

Different plastics have different mechanical, thermal, and chemical properties. Below are some of the most commonly machined:

1. Acrylic (PMMA)

-

Transparent, strong, lightweight

-

Common in display parts and lenses

2. Delrin (POM)

-

Excellent dimensional stability

-

Used in gears, bearings, and bushings

3. PTFE (Teflon)

-

Low friction and chemical resistance

-

Ideal for sealing parts and fluid systems

4. Polycarbonate (PC)

-

High impact resistance

-

Used in enclosures, guards, and optical lenses

5. PEEK

-

High heat and chemical resistance

-

Aerospace and medical-grade applications

6. Nylon

-

Strong and flexible

-

Excellent for mechanical parts like rollers and gears

Essential CNC Machines for Plastic Machining

To ensure efficient and accurate results, it’s crucial to use the right machine types:

1. 3-Axis CNC Milling Machines

-

Best for flat parts and simple features

-

Easily handles pocketing, profiling, and drilling

2. 5-Axis CNC Machines

-

Ideal for complex geometries and curved surfaces

-

Enables part access from multiple directions without repositioning

3. CNC Routers

-

Optimized for softer plastics and sheet material

-

Faster but less rigid than traditional mills

4. CNC Lathes

-

Perfect for cylindrical plastic parts such as bushings or threads

Key Considerations When Machining Plastic

Plastic behaves very differently from metals. Here are some important machining strategies:

1. Avoid Overheating

Plastics have low melting points. Excess heat can deform the part or cause tool buildup.

Solution: Use sharp tools, proper chip evacuation, and air or mist cooling.

2. Choose Proper Tooling

Use tools designed for plastics—usually single-flute or polished cutters—to avoid chip welding and ensure clean edges.

3. Control Clamping Pressure

Plastics are softer and more flexible than metals. Over-clamping can deform the part or affect dimensional accuracy.

4. Optimize Feed and Speed

-

Higher RPMs generally work well

-

Moderate feed rates prevent material from melting on the tool

5. Account for Material Expansion

Plastic expands with heat more than metals. This must be considered for high-precision applications.

CNC Machining vs. Injection Molding for Plastic

CNC Machining

-

Lower setup cost

-

Ideal for prototypes and short-run production

-

No molds required

-

Quick lead time

Injection Molding

-

High upfront tooling cost

-

Better for mass production

-

Consistent unit cost over large volumes

When time, cost flexibility, or customization is needed, CNC machining is the preferred choice—especially for early-stage product development.

Industries That Use CNC Machines for Plastics

1. Medical

-

Surgical instruments, diagnostic device enclosures, fluidic components

-

Biocompatibility and sterility are key concerns

2. Aerospace

-

Interior cabin parts, brackets, non-structural fittings

-

Weight savings and chemical resistance are critical

3. Electronics

-

Insulating housings, connectors, and switch components

-

Requires thermal and dielectric stability

4. Automotive

-

Dashboard assemblies, air handling components, under-the-hood clips

-

Plastics reduce vehicle weight and improve fuel economy

5. Consumer Goods

-

Sporting equipment, packaging prototypes, home appliances

-

Often demand fine finishes and tight tolerances

Common Challenges and How to Overcome Them

1. Burr Formation

Some plastics tend to leave burrs at the edge.

Solution: Deburr using post-machining finishing techniques like flame polishing or tumbling.

2. Tool Melting or Smearing

Heat build-up can cause plastic to melt onto the cutter.

Solution: Ensure proper cooling and clean, sharp tools.

3. Dimensional Inaccuracy

Thermal expansion or part flexing during clamping can result in off-spec dimensions.

Solution: Use proper fixturing and adjust for thermal behavior in the design phase.

Tips for CNC Plastic Part Design

-

Avoid thin walls to minimize vibration or warping

-

Use fillets rather than sharp internal corners for easier machining

-

Consider part orientation to reduce unsupported spans

-

Leave extra stock for finishing operations if surface quality is critical

Finishing Options for CNC Plastic Parts

Post-machining processes enhance aesthetics and functionality:

-

Vapor Polishing: For transparent plastics like polycarbonate and acrylic

-

Anodizing (for hybrid parts): If metal inserts are used

-

Painting or Coating: For color matching or added protection

-

Laser Marking: For branding, labeling, or serialization

Environmental Advantages of Machining Plastic

CNC machining for plastic reduces material waste compared to subtractive methods. Moreover, most engineering plastics are recyclable or reusable in non-critical applications. For companies prioritizing sustainability, using recyclable plastics in CNC processes supports eco-conscious manufacturing.

Final Thoughts

CNC machines designed or optimized for plastic machining offer manufacturers the ability to create complex, durable, and precise components without the long lead times or high tooling costs associated with molding. From one-off prototypes to short production runs, these machines provide an excellent combination of speed, accuracy, and flexibility.

Whether you're an OEM, startup, or product designer, understanding the nuances of plastic materials and machining processes will empower you to produce high-quality parts that meet your performance goals. As industries continue to push for lightweight, high-performance, and cost-effective components, CNC plastic machining is a vital part of the future of precision manufacturing.