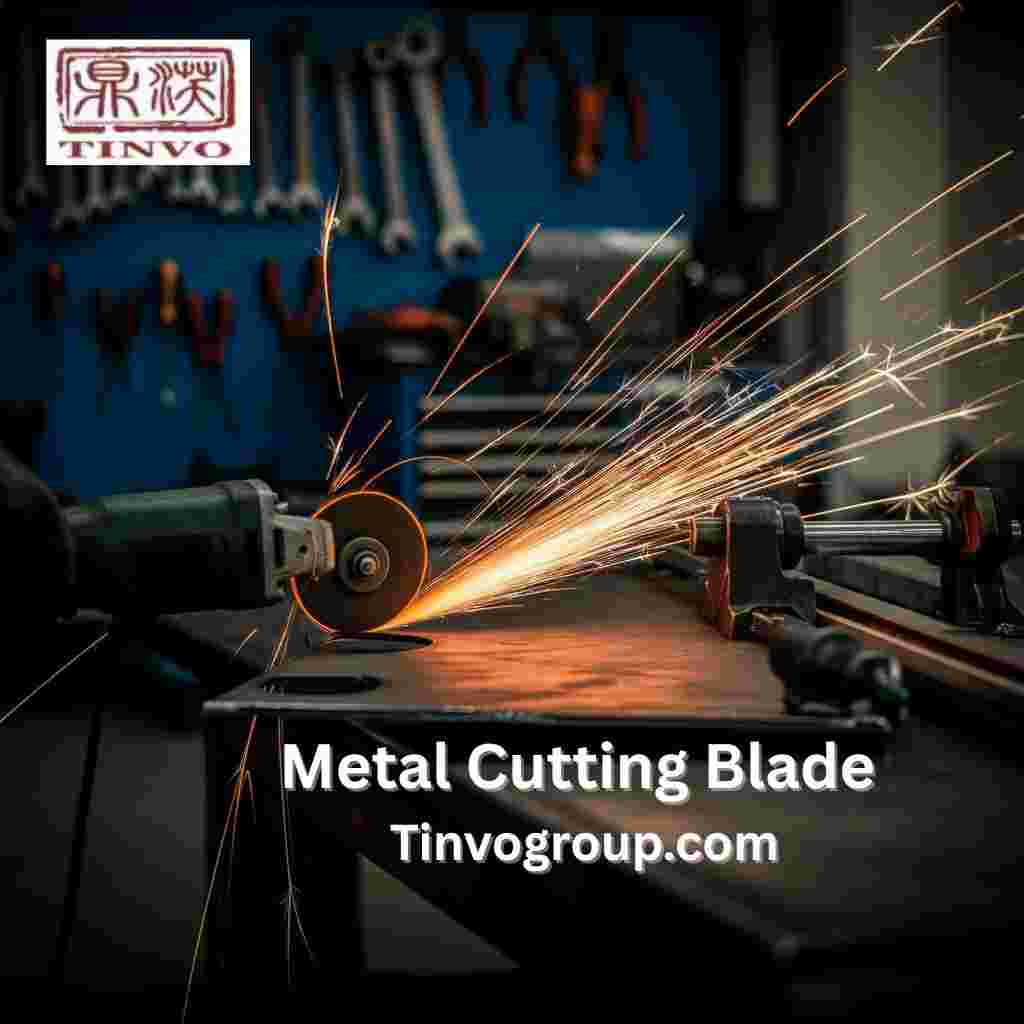

When it comes to shaping and cutting metal, angle grinders equipped with the right metal cutting blade emerge as indispensable tools. Whether you’re a professional working in industries like hot rolling mills and finishing rolling mills or a DIY enthusiast tackling a weekend project, selecting the right cutting blade makes all the difference. With TinvoGroup’s extensive expertise in blades and metalworking tools, we’re here to guide you through the best options, applications, and tips for maintaining your metal cutting blade.

Understanding Metal Cutting Blades

A metal cutting blade is specifically designed to handle the stress and heat involved in cutting through materials like steel, aluminum, and other metals. These blades attach to angle grinders, which operate at high speeds to make precise and efficient cuts.

Choosing the best blade for your needs involves several considerations, from material type to performance requirements. TinvoGroup offers a variety of cutting solutions, including blades designed for specialized industrial applications like flying shear blades used in hot rolling mills.

Popular Types of Metal Cutting Blades

Not all metal cutting blades are created equal. Here are some of the most commonly used types and their recommended applications:

Abrasive Blades

These are made from a combination of materials like aluminum oxide or silicon carbide and are ideal for cutting hard metals such as steel. They are commonly used in metal fabrication projects, offering affordability and reliability.

Carbide-Tipped Blades

Known for their durability, carbide-tipped blades are designed for heavy-duty applications. They are perfect for those who frequently cut stainless steel or other dense materials.

Diamond Blades

Though often associated with masonry, diamond blades are increasingly used for cutting metal. Their long lifespan and ability to handle extreme conditions make them a great option for industrial users.

Specialized Industrial Blades

TinvoGroup specializes in flying shear blades, which are built for precision in hot and finishing rolling mills. These blades excel in high-speed environments where durability and performance are critical.

How to Select the Best Metal Cutting Blade

Selecting the right metal cutting blade for your angle grinder starts with understanding your project requirements. Here’s a step-by-step guide:

1. Match the Blade to the Material

The material you’re cutting determines the type of blade needed. Abrasive blades work well for ferrous metals, while carbide-tipped or diamond blades are better suited for tougher materials like stainless steel.

2. Consider Blade Size

Angle grinders come in different sizes, typically ranging from 4.5 inches to 9 inches in diameter. Ensure the blade size matches your grinder for optimal performance.

3. Prioritize Durability

For industries like hot rolling mills and straightening machines, blade durability is a critical factor. Tools exposed to continuous high-speed use, such as flying shear blades, require high-grade materials that can withstand intense pressure and heat.

4. Budget for Quality

While abrasive discs are economical, investing in higher-quality blades like carbide-tipped ones can lead to cost savings in the long run due to their extended lifespan. TinvoGroup’s product range includes durable, cost-effective options tailored to industrial and personal needs.

Applications of Metal Cutting Blades

From industrial workshops to home projects, cutting blades enable users to tackle a variety of tasks. Here are some common applications:

- Hot Rolling Mills

The metalworking industry relies on cutting blades for processes like shearing and shaping hot metal in fabrication lines. TinvoGroup’s flying shear blades are engineered for high performance in these demanding environments.

- Finishing Rolling Mills

Blades that cut with high precision are critical to operations in finishing rolling mills. Products from TinvoGroup ensure smooth and exact cuts that meet industry standards.

- Straightening Machines

Metal cutting blades are also integral to straightening machines, which require clean cuts to align and shape pieces accurately. Engineered solutions from TinvoGroup can handle high-volume operations with ease.

- DIY Projects

Whether you’re installing a steel frame or cutting aluminum for backyard crafting, a reliable metal cutting blade attached to your angle grinder gets the job done efficiently.

Maintenance Tips for Metal Cutting Blades

Maximizing the efficiency and lifespan of your metal cutting blade doesn’t stop with selection—it also depends on how you use and maintain it. Follow these essential tips:

1. Regularly Inspect the Blade

Check for visible wear, cracks, or unevenness. Damaged blades may compromise safety and performance, so replace them as soon as defects are noticed.

2. Use the Right Speed

Ensure your angle grinder’s operating speed matches the specifications of your blade. Exceeding the maximum RPM can lead to overheating and degrade the blade.

3. Avoid Overheating

Excessive heat weakens the blade’s structure. To prevent overheating, apply light and steady pressure during cuts rather than forcing the blade through the material.

4. Store Properly

Always store your blades in a cool, dry place. Moist or humid conditions can cause abrasive blades to degrade over time, while improper stacking might lead to warping or cracking.

5. Clean Debris

Don’t forget to clean your blade after each use. Metal shavings and debris can accumulate and impact its cutting performance.

6. Buy Reliable Blades

Invest in high-quality products from reputable suppliers like TinvoGroup. High-grade materials and precision engineering ensure you get the best value over time.

Why Choose TinvoGroup’s Metal Cutting Blades?

TinvoGroup is a trusted name in the industry, known for crafting cutting-tool solutions that meet global standards. Whether it’s providing high-performance flying shear blades or engineering custom cutting solutions for specific applications like hot rolling mills and straightening machines, we bring innovation and consistency to your projects.

Our cutting blades marry durability with precision, ensuring you achieve clean cuts every time. Plus, we back our products with expert advice, helping you select the blade ideally suited to your requirements.

Final Thoughts

Selecting the right metal cutting blade for your angle grinder can transform how effectively and efficiently you complete tasks. Whether you need a blade for industrial use in finishing rolling mills, a precise shearing solution like a flying shear blade, or a durable option for personal projects, TinvoGroup has you covered.

By choosing quality tools, maintaining them properly, and ensuring their compatibility with your grinder, you'll extend their lifespan and enhance your cutting experience. Explore TinvoGroup’s wide range of metal cutting solutions to ensure every cut is sharp, precise, and reliable.