Plastic injection molding has become a cornerstone manufacturing process for countless industries, from automotive and electronics to medical devices and consumer goods. Its ability to produce large quantities of high-quality parts with precise tolerances makes it indispensable for businesses worldwide. However, choosing the right plastic injection molding service is not as simple as picking the first provider you find. The wrong choice can lead to production delays, quality issues, and unnecessary costs, while the right partner ensures consistent performance, innovation, and cost-efficiency.

In this article, we will explore the essential considerations for selecting a plastic injection molding service provider that aligns with your business goals. We’ll dive into aspects such as understanding your specific needs, evaluating technical capabilities, ensuring quality standards, cost and efficiency factors, and the importance of customer service and support.

Understanding Your Specific Business Needs

Before engaging any plastic injection molding provider, the first step is to understand your own production requirements thoroughly. Different projects have unique demands based on design complexity, material choice, and production volume. For example, manufacturing components for the automotive industry requires high durability and resistance to extreme temperatures, while consumer goods often prioritize aesthetics and cost-efficiency. Clearly defining these parameters will help you filter out providers that cannot meet your specifications.

Consider creating a detailed project brief that includes your part designs, material preferences, expected tolerances, and projected production volume. This document will serve as a foundation for meaningful discussions with potential providers. A well-defined brief ensures you communicate your needs effectively and helps the supplier evaluate whether they have the resources and capabilities to meet your expectations. It’s a critical first step to ensure alignment from the beginning.

Evaluating Technical Capabilities and Expertise

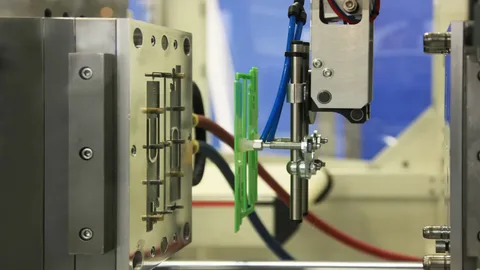

When choosing a plastic injection molding service, their technical expertise and equipment capabilities should be top priorities. The best providers invest in state-of-the-art machinery that ensures precision, repeatability, and efficiency in the molding process. Advanced injection molding machines, along with technologies like multi-cavity molds and automated systems, can significantly impact the quality and speed of your production. It’s essential to ask potential suppliers about their equipment, technology stack, and experience handling projects similar to yours.

Additionally, consider the provider’s expertise in mold design and engineering. A high-quality mold is the backbone of a successful injection molding process. An experienced provider will offer services like mold flow analysis and design for manufacturability (DFM) to identify potential issues before production begins. These proactive measures can save time and reduce costly errors later in the process. The right partner will not only have advanced machinery but also the engineering know-how to optimize your product design for both performance and cost.

Ensuring Quality Control and Compliance Standards

Quality is non-negotiable in plastic injection molding. Even minor defects can compromise the functionality of a product, leading to customer dissatisfaction and reputational damage. Therefore, when selecting a provider, inquire about their quality assurance processes. Do they follow internationally recognized standards like ISO 9001 or ISO 13485 for medical devices? Are they committed to rigorous inspections and testing at every stage of production? These certifications and practices indicate a serious commitment to quality.

Beyond certifications, ask about specific quality control measures. This includes dimensional inspections, material traceability, and in-process monitoring to detect and correct deviations early. A robust quality control system minimizes defects, reduces waste, and ensures that every part meets your specifications. Remember, quality is not just about meeting industry standards; it’s about exceeding your customer’s expectations. Partnering with a provider that prioritizes quality assurance will give you confidence in every batch of products delivered.

Analyzing Cost, Lead Times, and Efficiency

Cost is an important factor, but it should never be the sole criterion when choosing a plastic injection molding service. Low prices can sometimes mean compromised quality or hidden charges later in the project. Instead, focus on cost-effectiveness, which balances competitive pricing with high-quality results and timely delivery. Ask for detailed quotes that break down expenses for tooling, material, labor, and post-production services. This transparency will help you make accurate comparisons between providers.

Lead times are equally critical, especially if you operate in a fast-moving market. Delays in production can disrupt your supply chain and impact your bottom line. Discuss timelines upfront and evaluate whether the provider has the capacity to handle urgent or large-volume orders without sacrificing quality. Efficient providers often use advanced scheduling systems and maintain buffer capacities to meet fluctuating demands. A reliable partner will prioritize your deadlines while maintaining the highest quality standards, ensuring you remain competitive in your industry.

Prioritizing Communication and After-Sales Support

Strong communication is the backbone of any successful partnership. A responsive and transparent plastic injection molding provider can make a significant difference in your project’s success. From the initial consultation to post-production support, you should feel confident that the supplier understands your needs and keeps you informed throughout the process. Clear communication helps address design changes, material adjustments, and unforeseen challenges quickly and effectively.

After-sales support is another critical consideration. The right provider will stand behind their work, offering assistance with part replacements, mold maintenance, or adjustments if needed. This ongoing support not only ensures long-term product quality but also strengthens your business relationship. A supplier who values communication and provides comprehensive after-sales service demonstrates reliability and commitment, making them a valuable partner in your supply chain.

Final Thoughts

Choosing the right plastic injection molding service is a strategic decision that directly impacts your product quality, production efficiency, and overall profitability. By understanding your specific requirements, evaluating technical expertise, ensuring strict quality standards, analyzing cost-efficiency, and prioritizing communication, you can identify a partner that aligns with your business goals.