In the harsh world of quarry equipment, every component is pushed to its limits. The immense loads, constant dust, and abrasive conditions place incredible stress on heavy-duty hydraulics. At the heart of many of these powerful machines are Poclain hydraulic motors, known for their exceptional torque and reliability. However, even the most robust components require a proactive approach to maintenance to ensure their longevity. This article will focus on the critical importance of hydraulic motor preventive maintenance for Poclain motors in quarry environments. We will provide a detailed guide on how to protect these vital components from specific challenges like high loads and contamination, outlining key preventive measures, regular inspections, and the importance of using genuine Poclain parts to minimize costly downtime and ensure the continuous operation of your machinery.

The Unique Risks of Quarry Operations for Hydraulic Motors

Quarry equipment maintenance presents unique challenges that are particularly harsh on hydraulic motors. Understanding these risks is the first step to effective prevention.

-

Abrasive Contamination: Fine rock dust and sand are pervasive in quarries. This abrasive contamination can easily enter the hydraulic system through worn seals and breathers. Once inside, it acts like sandpaper, causing rapid wear to the precision-machined surfaces of the Poclain motor, leading to a loss of efficiency and eventual failure.

-

Extreme Loads and Stress: Poclain hydraulic motors are designed for high load conditions, but the constant, repetitive strain of digging and moving heavy rock can lead to fatigue in components. Overloading the motor or subjecting it to sudden, violent impacts can cause internal damage to bearings, seals, or the shaft.

-

High Operating Temperatures: Continuous heavy-duty work generates significant heat. An overheating hydraulic system can degrade the hydraulic fluid, reducing its lubricating properties and accelerating wear on the motor's internal parts.

-

Vibration and Misalignment: Constant vibration from rocky terrain can loosen fittings and cause stress on the motor's shaft and bearings. Misalignment of the motor during installation can also lead to premature wear and failure.

A Preventive Maintenance Checklist for Poclain Hydraulic Motors

A proactive maintenance schedule is the best defense against these risks. The following checklist is essential for ensuring the longevity of your Poclain hydraulic motors.

1. Hydraulic Fluid Management:

-

Check Fluid Quality and Level: Regularly inspect the hydraulic fluid in the reservoir. The fluid should be clean and clear. Milky or cloudy fluid indicates water contamination, while a dark color or burnt smell suggests overheating.

-

Adhere to a Strict Filter Schedule: The filters are the primary defense against contamination. Follow the manufacturer's recommended schedule for hydraulic fluid filter replacement, or even shorten the intervals in a dusty quarry environment.

-

Fluid Analysis: Periodically take samples of the hydraulic fluid for lab analysis. This can detect microscopic metal particles and water contamination, providing an early warning sign of internal component wear long before a failure occurs.

2. Regular Inspections:

-

Visual Inspection: Routinely check the Poclain motor casing, hoses, and fittings for any signs of leaks, damage, or external corrosion. Pay close attention to the shaft seal for any signs of fluid loss.

-

Temperature Monitoring: Monitor the motor's temperature during operation. An unusually hot motor can be a sign of internal leakage or another problem.

-

Listen for Abnormal Noise: A healthy hydraulic motor runs quietly. A grinding, whining, or rattling noise can be a sign of aeration, cavitation, or damaged bearings. This requires immediate diagnostics.

3. The Importance of Quality Parts for Maintenance and Repair

For any hydraulic repair or component replacement, the choice of spare parts is paramount. In the demanding environment of a quarry, using genuine Poclain parts is a strategic decision that guarantees:

-

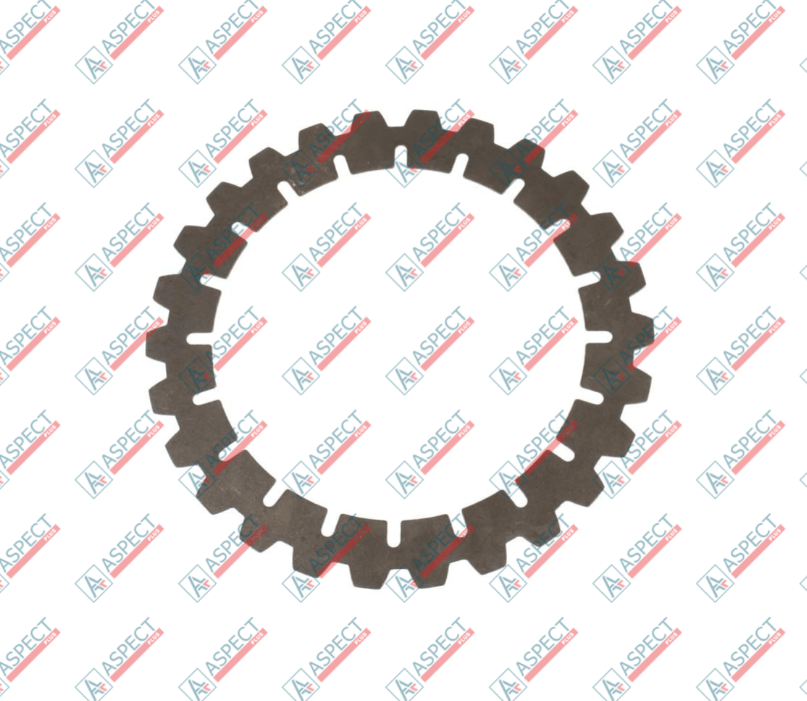

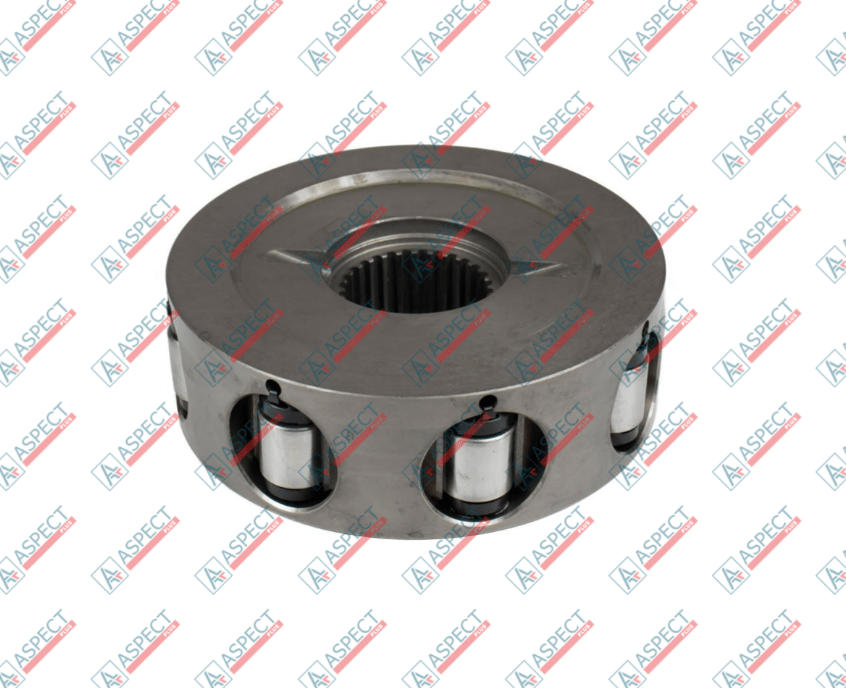

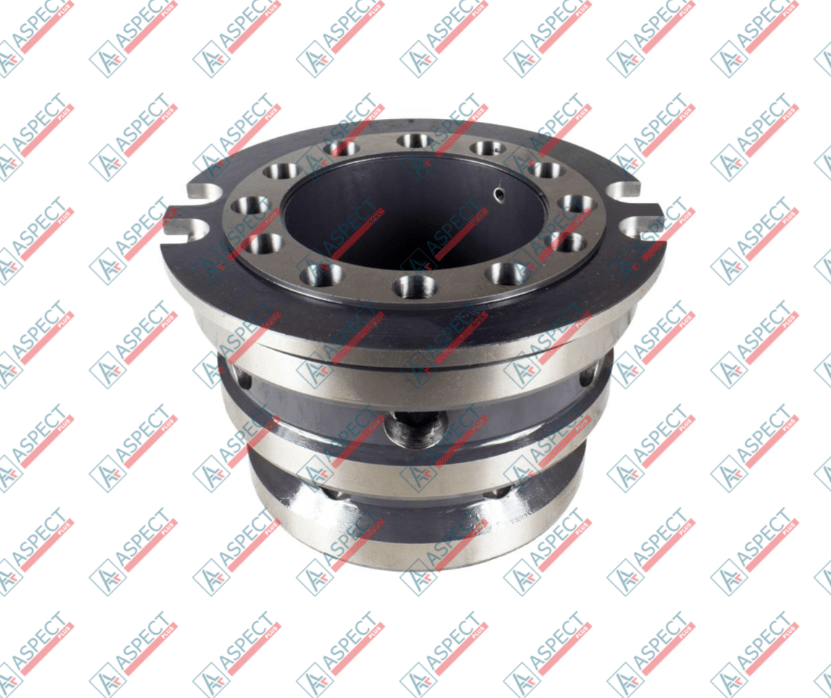

Superior Material Quality: Genuine Poclain parts are manufactured from high-grade materials specifically chosen to withstand the high pressures and stresses of heavy-duty hydraulics.

-

Perfect Fit and Performance: An original part is engineered to the exact specifications of the motor, ensuring perfect fit and restoring it to its original factory performance and efficiency.

-

Increased Durability: While a cheaper alternative may save money initially, it often fails prematurely under the rigors of quarry work, leading to repeated repairs and higher long-term costs.

Our company Aspect Plus offers a wide range of genuine Poclain parts and expert consultation to help you maintain your quarry equipment and prevent unexpected failures. We can provide high-quality seals, bearings, and other components that are vital for the longevity and reliability of your hydraulic system.

Conclusion

Hydraulic motor preventive maintenance is the most effective strategy for ensuring the continuous and reliable operation of your quarry equipment. By understanding the unique risks of the environment, implementing a proactive maintenance schedule, and committing to using genuine Poclain parts for any repair or replacement, you can significantly extend the longevity and performance of your Poclain hydraulic motors. This proactive approach not only minimizes the risk of unexpected failures and costly downtime but also safeguards your investment and ensures your machinery is always ready to perform.

For professional support, expert diagnostics, and a trusted source for quality parts for your Poclain hydraulic system, contact the specialists at Aspect Plus. We are here to help you keep your heavy equipment operating flawlessly.