IMARC Group's "Mobile Tempered Glass Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a complete roadmap for establishing a mobile tempered glass manufacturing plant. The report covers every critical aspect, including unit operations, raw material requirements, utility supply, plant infrastructure, machinery specifications, manpower requirements, transportation needs, and packaging solutions.

In addition to operational insights, the study also delivers a comprehensive financial analysis, addressing capital investment, setup costs, project funding, operating expenses, income and expenditure forecasts, fixed and variable costs, ROI, profit projections, and net present value (NPV). This structured evaluation assists entrepreneurs and investors in determining feasibility and profitability before venturing into the mobile tempered glass industry.

What is Mobile Tempered Glass?

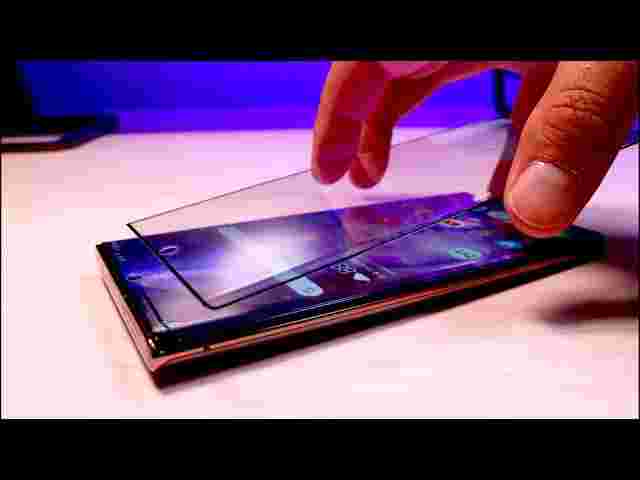

Mobile tempered glass, also known as smartphone screen protector or mobile display glass, is a specialized protective glass made from chemically strengthened glass sheets designed for mobile devices. It is widely valued in the smartphone accessories market, electronics retail, and device protection applications due to its ability to provide superior scratch resistance, impact protection, and crystal-clear visibility. Mobile tempered glass is often used as a essential protective solution for smartphones and tablets, offering reliable screen protection with high transparency and touch sensitivity retention.

The quality of mobile tempered glass depends on factors such as glass substrate purity, chemical tempering process, surface hardness rating, optical clarity, and compliance with international safety and quality standards.

Request to Get the Sample Report: https://www.imarcgroup.com/mobile-tempered-glass-manufacturing-plant-project-report/requestsample

How is Mobile Tempered Glass Produced?

Mobile tempered glass is manufactured through a specialized glass processing method and is valued for its protective properties and optical clarity. The production process involves several key steps:

- Glass Substrate Preparation: High-quality glass sheets are cut and shaped to precise dimensions matching various mobile device screen sizes. Quality control ensures all glass substrates meet thickness and clarity specifications.

- Surface Treatment and Cleaning: After cutting, the glass surfaces are thoroughly cleaned and treated to remove any impurities or residues. This creates the optimal surface condition for the tempering process.

- Chemical Tempering Process: The glass sheets are then immersed in molten potassium salt baths at controlled temperatures. This ion-exchange process strengthens the glass by replacing smaller sodium ions with larger potassium ions, creating compressive stress on the surface.

- Quality Testing and Finishing: Once tempered, the glass undergoes rigorous quality testing including hardness measurement, optical clarity assessment, and impact resistance testing. Additional treatments such as oleophobic coating application and precision edge polishing are applied to enhance performance.

Market Trends and Drivers of Mobile Tempered Glass

The global mobile tempered glass market is expanding due to increasing demand for smartphone screen protection, growing mobile device penetration, and expanding applications in tablets and wearable device protection. Rising interest in premium device accessories and advanced protective solutions is driving adoption. Additionally, the use of mobile tempered glass in retail accessories market, online sales channels, and specialty electronics stores further enhances its market prospects.

Key Aspects to Setup a Mobile Tempered Glass Manufacturing Plant

- Location to Setup Plant

- Market Research and Demand Analysis

- Plant Layout and Infrastructure

- Construction and Setup Requirements

- Procurement of Equipment and Machinery

- Documentation and Licenses

- Cost Analysis

Requirements to Setup a Facility

- Funds and Capital Investment

- Machinery for Glass Processing and Tempering

- Land and Infrastructure

- Skilled Workforce and Quality Experts

Types of Costs to Setup a Factory

- Land, Location, and Site Development Costs

- Plant Layout and Construction Costs

- Machinery and Equipment Procurement Costs

- Raw Material Costs (Glass Substrates, Chemical Solutions, Coatings)

- Packaging and Distribution Costs

- Transportation Costs

- Utility and Energy Costs

- Human Resource and Labor Costs

Project Economics

- Capital Investments

- Operating Costs

- Revenue Projections

- Expenditure Estimates (Fixed and Variable)

- Taxation and Depreciation

- Profit Projections

- Financial Analysis (ROI, NPV, Break-even)

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=17861&flag=C

Key Questions Answered in the Report

- What is the current market demand and export potential for mobile tempered glass?

- What are the main stages in the mobile tempered glass production process?

- What raw materials and machinery are required for efficient production?

- What certifications and quality standards must be met?

- What is the projected production cost structure and profitability outlook?

- What is the expected ROI and payback period for a mobile tempered glass manufacturing plant?

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Services:

- Plant Setup

- Factory Audit Services

- Factory Setup Services

- Regulatory Approvals and Licensing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145