When it comes to modern rice milling, one of the most important components is the rice rubber roller. These rollers are widely used in rice mills for the dehusking process, where paddy grains are efficiently stripped of their husks. The performance, durability, and efficiency of a rice mill largely depends on the quality of the rubber roller. For mill owners, farmers, and rice processors, the price of rice rubber rollers is a critical factor that directly affects production costs and overall profitability.

In this blog, we'll explore the factors that determine rice rubber roller price, the average cost range, and tips to make the right purchase for long-term value.

What is a Rice Rubber Roller?

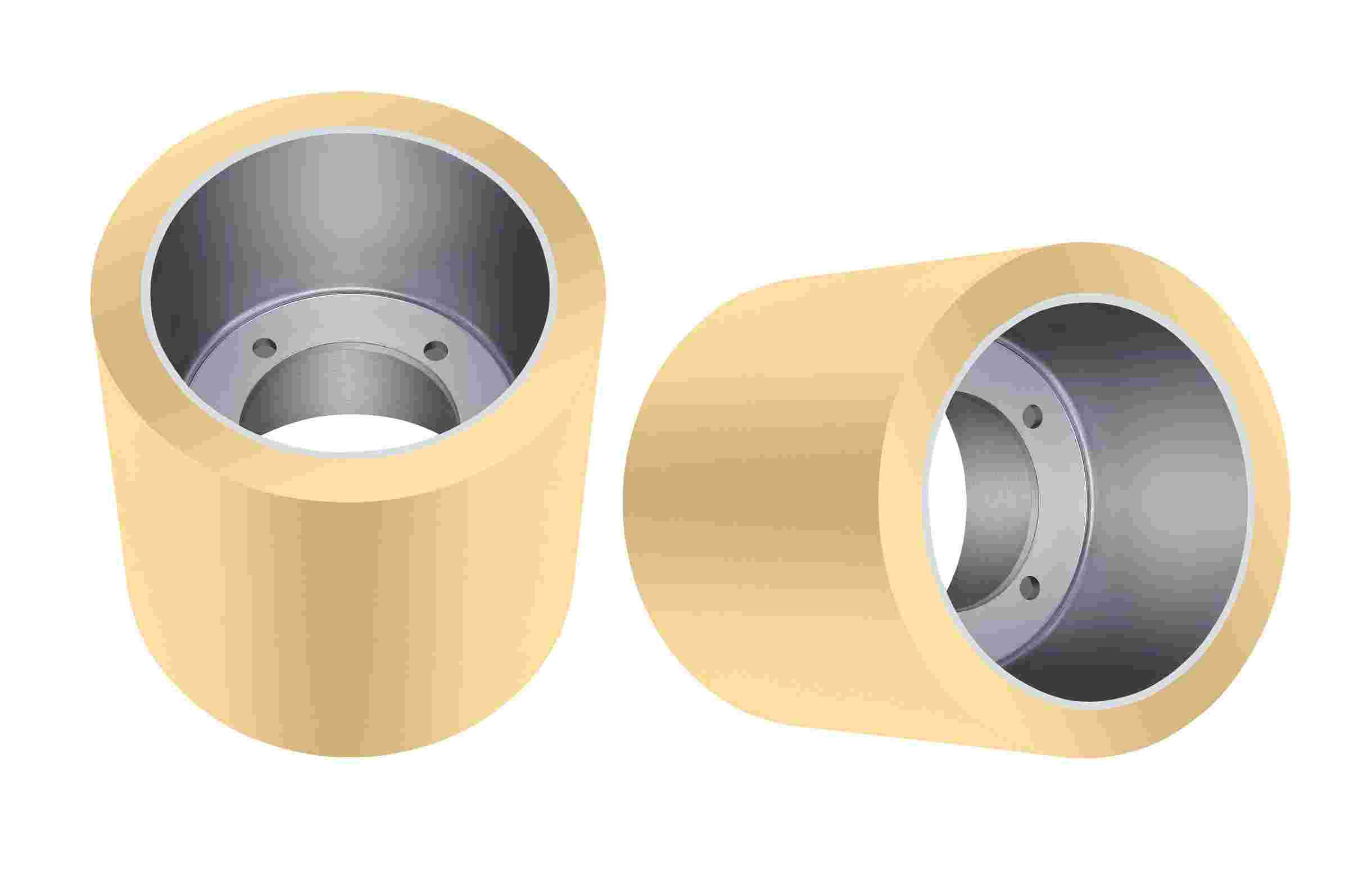

A rice rubber roller is a cylindrical product made of rubber and metal, designed for husking rice grains. It works in pairs to dehusk paddy by applying pressure and friction. Compared to traditional hulling machines, rubber rollers reduce breakage, improve milling yield, and deliver better-quality rice.

Because of their role in productivity, choosing the right roller at the right price becomes essential for rice millers.

Factors Affecting Rice Rubber Roller Price

The cost of rice rubber rollers varies depending on several factors. Understanding these will help buyers make informed purchasing decisions.

1. Size and Dimension

Rubber rollers are available in different sizes, such as 6” x 8.75”, 10” x 10”, and other customized dimensions. Larger rollers with greater husking capacity generally cost more.

2. Quality of Rubber

Natural rubber and synthetic rubber are used in roller production. Rollers with high-quality rubber content provide longer life, less breakage, and better efficiency. While these are priced higher, they save costs in the long run.

3. Brand and Manufacturer

Well-established brands often charge slightly higher prices due to better quality assurance and consistency. Local manufacturers may offer lower prices, but performance and durability might vary.

4. Country of Origin

Rice rubber rollers manufactured in countries like India, China, and Vietnam may differ in price due to production costs, raw material availability, and export policies. Imported rollers can be more expensive due to shipping and duties.

5. Durability and Lifespan

High-grade rollers usually last longer, sometimes processing 80–100 tons of rice before needing replacement. The longer the lifespan, the better the cost-efficiency.

6. Bulk Purchase Discounts

Many suppliers provide discounts on bulk orders. For large rice mills, buying in bulk reduces the overall cost per roller.

Rice Rubber Roller Price Range

While prices fluctuate based on region and supplier, here is a general idea of the average rice rubber roller price range:

-

Small Rollers (6-inch) → ₹700 to ₹1,200 per piece

-

Medium Rollers (8–10 inch) → ₹1,500 to ₹2,500 per piece

-

Premium Quality / Imported Rollers → ₹2,500 to ₹4,500 per piece

In international markets, prices typically range from $10 to $40 per piece, depending on specifications and order quantity.

Why Price Matters in Rice Milling

At first glance, it may seem cost-effective to buy cheaper rollers. However, rollers of inferior quality wear out quickly, leading to frequent replacements and downtime in milling. This not only increases maintenance costs but also lowers milling yield.

By investing in slightly higher-priced, premium-quality rollers, rice millers can achieve:

-

Better husking efficiency

-

Reduced grain breakage

-

Higher recovery rate of full grains

-

Lower long-term operational costs

In short, the real value lies in balancing price and performance .

Tips for Buying Rice Rubber Rollers at the Right Price

If you are planning to purchase rice rubber rollers, here are some useful tips:

-

Compare Multiple Suppliers – Always request quotes from at least 3–4 suppliers to get the best deal.

-

Check Durability Guarantees – Ask about expected lifespan in terms of tons processed.

-

Avoid Only Price-Based Decisions – Cheap rollers might look attractive but often result in higher hidden costs.

-

Consider Bulk Orders – If you operate a large rice mill, buying in bulk reduces per-unit costs.

-

Look for Reviews and Feedback – Trusted brands with positive reviews are often worth the extra cost.

-

Check Warranty or Replacement Policies – Some manufacturers offer replacement guarantees if rollers wear out prematurely.