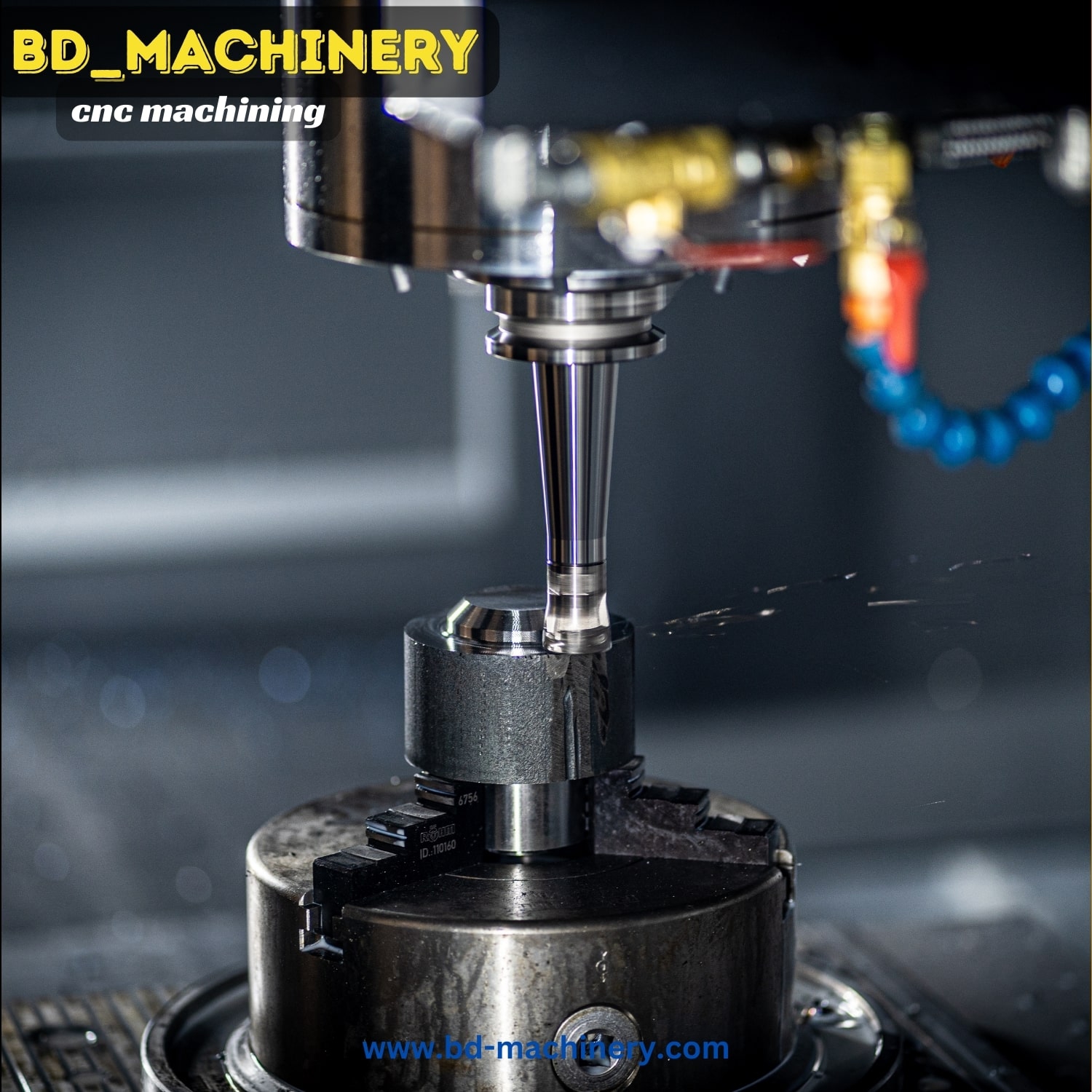

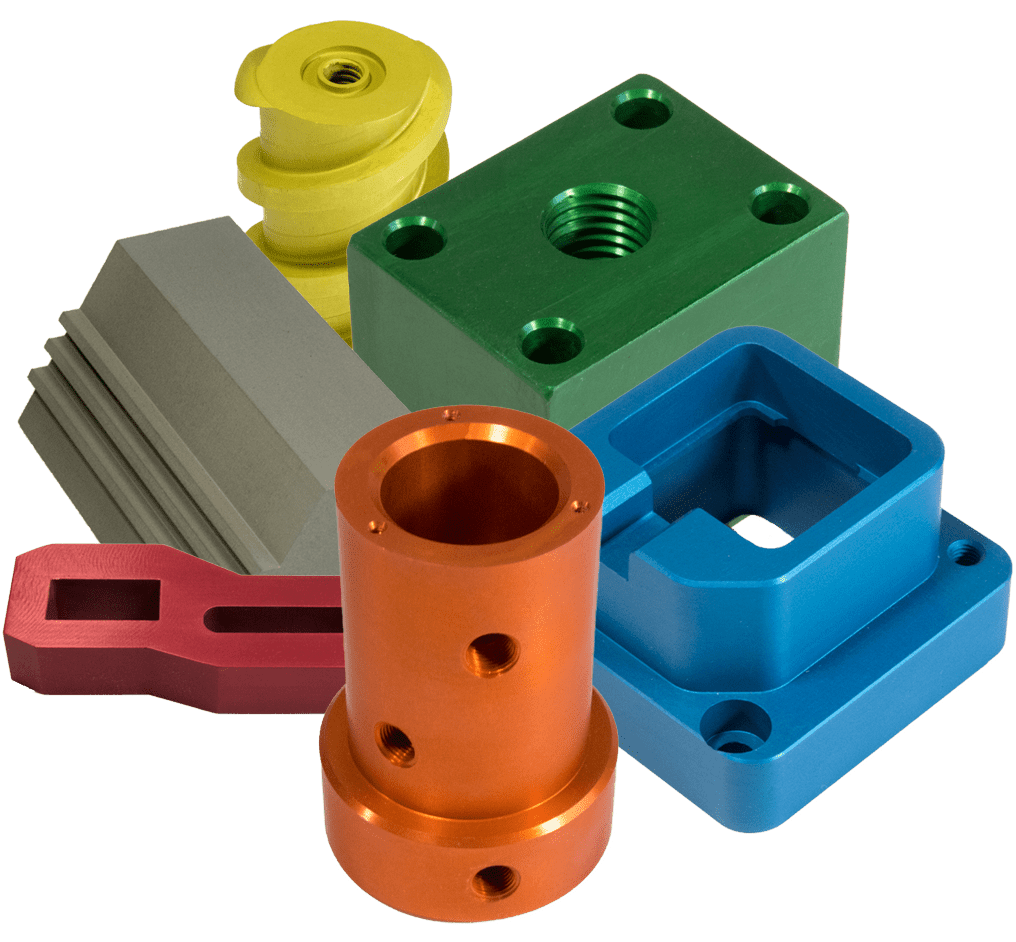

http://www.casting-steel.com/ heavy duty truck castings manufacturer Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and alloy steel, our company is a world class manufacturer and supplier of investment castings in China. It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 20,000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. The headquarters of our company is located in the famous industrial town Yinzhou, Ningbo in China. It is very convenient to be reached with an advantageous geographic position; it is located about 30 kilometers away from the Bei-lun Port which is the second biggest port in China, and about 15 kilometers away from the Lishe International Airport. The principal production base of the cast steel foundry is located in Qiucun Town, Fenghua, Ningbo, a distance of 15 kilometers away from the Headquarters. Our company was established in 1992, it covers a total area of 40,500 square meters and now has more than 500 employees, including 10 engineers and 60 technicians. The company owns a brand-new foundry, which covers an area of more than 30,000 square meters, and is equipped with several modern types of energy-saving; environmentally-friendly production lines including a fully automated wax and shell making process flow line, as well as two mesh belt furnace heat treatment production lines. The machining factory is located in Longxing headquarters and is fully equipped with complete and advanced CNC machining equipment including 20 vertical and horizontal machining centers and more than 30 NC machines, the machining facility is fully independent from the casting foundry and has an independent management team and tailored business model to suit. In addition to the casting, forging and machining, it also has the facility to machine various profiles. Our company also has the most advanced and complete inspection equipment in the casting industry, including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on. With these advanced facilities & instruments, we are able to supply the most precise finished products to our customers, and make products meeting their overall inspection requirements on chemical composition, mechanical properties, non-destructive testing and high precise dimensional inspections. Our products cover a wide range of industries including train; railway, automobile; truck, construction machinery, mining machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine ,hardware, power equipment and so on. We are capable to produce products according to customers’ drawings or samples, we focus on both carbon steel and alloy steel. Up to today, more than 100 raw materials and 5,000 kinds of different products have been developed and produced by us. We are familiar with the various industrial standards, such as Chinese GB, American ASTM, AISI , German DIN, French NF, Japanese JIS, British BS, Australian AS and Association of American Railroads (AAR ) and other industrial standards. Given that traditional foundries only provide castings, our company has completed a transformation and upgraded to a deep-processing manufacturer with expanded ng with their satisfaction, focusing on customer demands and exceeding their expectations”. With the enterprise spirit of “Moving with the times, pioneering and innovating, harmony and win-win, striving for excellence”, and based on the working-style of “Honesty and Practicality, Persevering Unremittingly, Teamwork Spirit, Achieving Greatness”, our company would like to sincerely invite the global prospective buyers to pay a visit and have a good cooperation for a splendid future together. If you are looking for China casting foundry, casting factory, casting company, investment casting foundry, lost wax casting foundry, steel casting foundries, precision casting foundries, please feel free to contact Qianhao Metal.heavy duty truck castings manufacturer website:

http://www.casting-steel.com/ http://www.casting-steel.com/ heavy duty truck castings manufacturer Specializing in the manufacturing of lost wax investment castings and finished products in carbon steel and alloy steel, our company is a world class manufacturer and supplier of investment castings in China. It consists of 2 major facilities, both steel casting foundry and CNC machining factory which enable us to supply both precision castings and finished products with an annual production capacity of over 20,000 tons, and the products are mainly exported to Europe, America, Japan and other destinations around the world. The headquarters of our company is located in the famous industrial town Yinzhou, Ningbo in China. It is very convenient to be reached with an advantageous geographic position; it is located about 30 kilometers away from the Bei-lun Port which is the second biggest port in China, and about 15 kilometers away from the Lishe International Airport. The principal production base of the cast steel foundry is located in Qiucun Town, Fenghua, Ningbo, a distance of 15 kilometers away from the Headquarters. Our company was established in 1992, it covers a total area of 40,500 square meters and now has more than 500 employees, including 10 engineers and 60 technicians. The company owns a brand-new foundry, which covers an area of more than 30,000 square meters, and is equipped with several modern types of energy-saving; environmentally-friendly production lines including a fully automated wax and shell making process flow line, as well as two mesh belt furnace heat treatment production lines. The machining factory is located in Longxing headquarters and is fully equipped with complete and advanced CNC machining equipment including 20 vertical and horizontal machining centers and more than 30 NC machines, the machining facility is fully independent from the casting foundry and has an independent management team and tailored business model to suit. In addition to the casting, forging and machining, it also has the facility to machine various profiles. Our company also has the most advanced and complete inspection equipment in the casting industry, including Spectrometer, Metallographic Microscope, Tension Tester, Low Temperature Tester, X-ray Tester, MPT, UT, CMM, Video Measurement Machine and so on. With these advanced facilities & instruments, we are able to supply the most precise finished products to our customers, and make products meeting their overall inspection requirements on chemical composition, mechanical properties, non-destructive testing and high precise dimensional inspections. Our products cover a wide range of industries including train; railway, automobile; truck, construction machinery, mining machinery, forklift, agricultural machinery, shipbuilding, petroleum machinery, construction, valve and pumps, electric machine ,hardware, power equipment and so on. We are capable to produce products according to customers’ drawings or samples, we focus on both carbon steel and alloy steel. Up to today, more than 100 raw materials and 5,000 kinds of different products have been developed and produced by us. We are familiar with the various industrial standards, such as Chinese GB, American ASTM, AISI , German DIN, French NF, Japanese JIS, British BS, Australian AS and Association of American Railroads (AAR ) and other industrial standards. Given that traditional foundries only provide castings, our company has completed a transformation and upgraded to a deep-processing manufacturer with expanded ng with their satisfaction, focusing on customer demands and exceeding their expectations”. With the enterprise spirit of “Moving with the times, pioneering and innovating, harmony and win-win, striving for excellence”, and based on the working-style of “Honesty and Practicality, Persevering Unremittingly, Teamwork Spirit, Achieving Greatness”, our company would like to sincerely invite the global prospective buyers to pay a visit and have a good cooperation for a splendid future together. If you are looking for China casting foundry, casting factory, casting company, investment casting foundry, lost wax casting foundry, steel casting foundries, precision casting foundries, please feel free to contact Qianhao Metal.heavy duty truck castings manufacturer website:http://www.casting-steel.com/