- 5 Bài viết

- 4 Ảnh

- 0 Videos

- 12/09/1998

Gần đây

- Electronics, Manufacturing, PCBA, Supply Chain, China Business

PCBA, Electronics Manufacturing, China Sourcing, SMT Assembly, Quality Control

How to Identify a Reliable China PCBA Manufacturer for High-Complexity Projects in 2025?

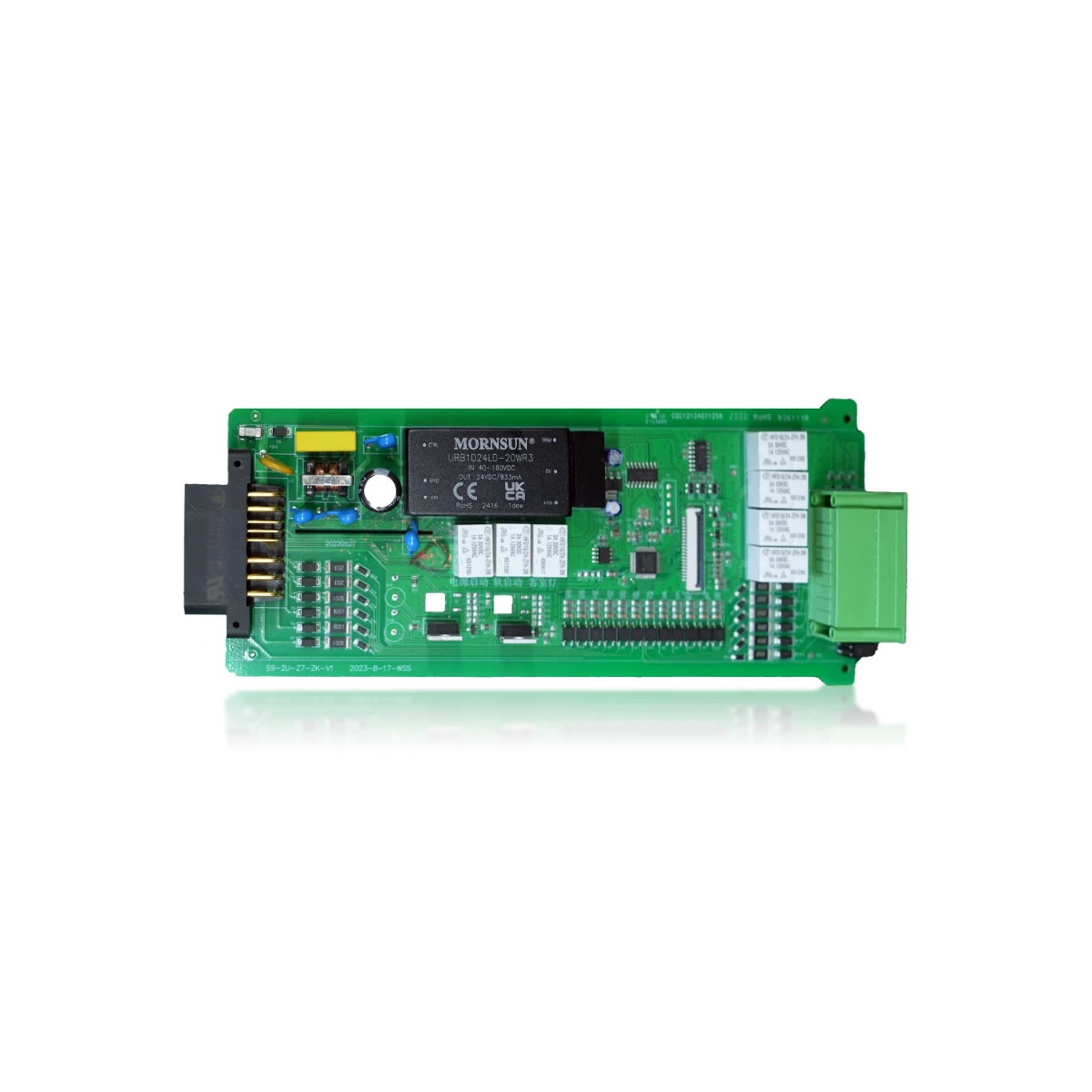

As electronics designs move toward extreme miniaturization and higher density, the gap between a standard assembly house and a high-quality China PCBA manufacturer is widening.

Technical reliability isn't just a buzzword—it's about the precision of SMT lines, the rigor of X-Ray/AOI inspection, and the depth of DFM support.

I’ve summarized the 5 key technologies that define a top-tier PCBA partner in today’s market. From solder paste inspection (SPI) to complex design verification, this guide provides a roadmap for OEMs looking to secure their supply chain quality.

Read the full technical breakdown here: [https://www.bundas24.com/blogs/194037/5-Key-Technologies-to-Identify-a-High-Quality-China-PCBA]

Special Focus: For those handling sophisticated layouts, don't miss the section on.

#PCBA #ElectronicsManufacturing #QualityControl #SMT #SupplyChain2025Electronics, Manufacturing, PCBA, Supply Chain, China Business PCBA, Electronics Manufacturing, China Sourcing, SMT Assembly, Quality Control How to Identify a Reliable China PCBA Manufacturer for High-Complexity Projects in 2025? As electronics designs move toward extreme miniaturization and higher density, the gap between a standard assembly house and a high-quality China PCBA manufacturer is widening. Technical reliability isn't just a buzzword—it's about the precision of SMT lines, the rigor of X-Ray/AOI inspection, and the depth of DFM support. I’ve summarized the 5 key technologies that define a top-tier PCBA partner in today’s market. From solder paste inspection (SPI) to complex design verification, this guide provides a roadmap for OEMs looking to secure their supply chain quality. Read the full technical breakdown here: [https://www.bundas24.com/blogs/194037/5-Key-Technologies-to-Identify-a-High-Quality-China-PCBA] Special Focus: For those handling sophisticated layouts, don't miss the section on. #PCBA #ElectronicsManufacturing #QualityControl #SMT #SupplyChain20250 Bình luận 0 Chia sẻ 2050 Lượt xemVui lòng đăng nhập để thích, chia sẻ và bình luận! - If you are looking to de-risk your hardware roadmap and improve your bottom line, this is a "must-read" resource. You can access the full technical breakdown and the "Ultimate Guide" here:If you are looking to de-risk your hardware roadmap and improve your bottom line, this is a "must-read" resource. You can access the full technical breakdown and the "Ultimate Guide" here:Strategic Sourcing: Why Turnkey PCBA in China is the Standard for 2026

Industry Insight: Navigating the New Era of Electronics Manufacturing

As we move into 2026, the global electronics supply chain is no longer just about "finding a factory"—it’s about strategic integration. For hardware startups and established OEMs alike, the volatility of component markets and the pressure of "Time-to-Market" have made the traditional, fragmented manufacturing model obsolete. Managing multiple vendors for PCB fabrication, component sourcing, and assembly is not only a logistical nightmare but a significant drain on capital.

In this landscape, Turnkey PCBA services in China have evolved from a convenience to a competitive necessity. By consolidating the entire lifecycle under one roof, companies can achieve professional PCBA cost management and drastic lead-time reductions. A reliable turnkey partner acts as an extension of your engineering team, identifying design flaws before they hit the production line and navigating the complexities of electronic manufacturing in China with local expertise.

Key Takeaways from the Full Guide:

To help you optimize your next production cycle, I’ve highlighted four critical value pillars from a recently published comprehensive guide:

Advanced DFM (Design for Manufacturing): Why professional engineering reviews are the first line of defense against costly production delays and soldering defects.

Intelligent Component Sourcing: Leveraging localized supply chains in China to secure authentic parts at scale, even during market fluctuations.

Rigorous Quality Control Standards: Beyond the basics—how adhering to IPC-A-610 and ISO 9001 certifications guarantees product reliability for mission-critical applications.

Lead-Time Optimization: Strategies for streamlining the transition from prototype to mass production without losing momentum.

Deep Dive & Next Steps

If you are looking to de-risk your hardware roadmap and improve your bottom line, this is a "must-read" resource. You can access the full technical breakdown and the "Ultimate Guide" here: Read the Full Article on WebYourself: The Ultimate Guide to Turnkey PCBA Services

Ready to optimize your manufacturing? For those seeking a practical, reliable partner to implement these turnkey strategies, Sanshun Smart stands out for their commitment to precision and "No MOQ" flexibility. Whether you need rapid prototyping or high-volume assembly, their team is ready to assist.

Get a Free Quote & DFM Consultation: Visit Sanshun Smart Official Website

#PCBA Assembly, #Supply Chain Optimization, #Electronics Manufacturing, #China Sourcing #Sanshun Smart0 Bình luận 0 Chia sẻ 592 Lượt xem - Strategic Sourcing: Why Turnkey PCBA in China is the Standard for 2026

Industry Insight: Navigating the New Era of Electronics Manufacturing

As we move into 2026, the global electronics supply chain is no longer just about "finding a factory"—it’s about strategic integration. For hardware startups and established OEMs alike, the volatility of component markets and the pressure of "Time-to-Market" have made the traditional, fragmented manufacturing model obsolete. Managing multiple vendors for PCB fabrication, component sourcing, and assembly is not only a logistical nightmare but a significant drain on capital.

In this landscape, Turnkey PCBA services in China have evolved from a convenience to a competitive necessity. By consolidating the entire lifecycle under one roof, companies can achieve professional PCBA cost management and drastic lead-time reductions. A reliable turnkey partner acts as an extension of your engineering team, identifying design flaws before they hit the production line and navigating the complexities of electronic manufacturing in China with local expertise.

Key Takeaways from the Full Guide:

To help you optimize your next production cycle, I’ve highlighted four critical value pillars from a recently published comprehensive guide:

Advanced DFM (Design for Manufacturing): Why professional engineering reviews are the first line of defense against costly production delays and soldering defects.

Intelligent Component Sourcing: Leveraging localized supply chains in China to secure authentic parts at scale, even during market fluctuations.

Rigorous Quality Control Standards: Beyond the basics—how adhering to IPC-A-610 and ISO 9001 certifications guarantees product reliability for mission-critical applications.

Lead-Time Optimization: Strategies for streamlining the transition from prototype to mass production without losing momentum.

Deep Dive & Next Steps

If you are looking to de-risk your hardware roadmap and improve your bottom line, this is a "must-read" resource. You can access the full technical breakdown and the "Ultimate Guide" here: Read the Full Article on WebYourself: The Ultimate Guide to Turnkey PCBA Services

Ready to optimize your manufacturing? For those seeking a practical, reliable partner to implement these turnkey strategies, Sanshun Smart stands out for their commitment to precision and "No MOQ" flexibility. Whether you need rapid prototyping or high-volume assembly, their team is ready to assist.

Get a Free Quote & DFM Consultation: Visit Sanshun Smart Official Website

#PCBA Assembly, #Supply Chain Optimization, #Electronics Manufacturing, #China Sourcing #Sanshun SmartStrategic Sourcing: Why Turnkey PCBA in China is the Standard for 2026 Industry Insight: Navigating the New Era of Electronics Manufacturing As we move into 2026, the global electronics supply chain is no longer just about "finding a factory"—it’s about strategic integration. For hardware startups and established OEMs alike, the volatility of component markets and the pressure of "Time-to-Market" have made the traditional, fragmented manufacturing model obsolete. Managing multiple vendors for PCB fabrication, component sourcing, and assembly is not only a logistical nightmare but a significant drain on capital. In this landscape, Turnkey PCBA services in China have evolved from a convenience to a competitive necessity. By consolidating the entire lifecycle under one roof, companies can achieve professional PCBA cost management and drastic lead-time reductions. A reliable turnkey partner acts as an extension of your engineering team, identifying design flaws before they hit the production line and navigating the complexities of electronic manufacturing in China with local expertise. Key Takeaways from the Full Guide: To help you optimize your next production cycle, I’ve highlighted four critical value pillars from a recently published comprehensive guide: Advanced DFM (Design for Manufacturing): Why professional engineering reviews are the first line of defense against costly production delays and soldering defects. Intelligent Component Sourcing: Leveraging localized supply chains in China to secure authentic parts at scale, even during market fluctuations. Rigorous Quality Control Standards: Beyond the basics—how adhering to IPC-A-610 and ISO 9001 certifications guarantees product reliability for mission-critical applications. Lead-Time Optimization: Strategies for streamlining the transition from prototype to mass production without losing momentum. Deep Dive & Next Steps If you are looking to de-risk your hardware roadmap and improve your bottom line, this is a "must-read" resource. You can access the full technical breakdown and the "Ultimate Guide" here: 👉 Read the Full Article on WebYourself: The Ultimate Guide to Turnkey PCBA Services Ready to optimize your manufacturing? For those seeking a practical, reliable partner to implement these turnkey strategies, Sanshun Smart stands out for their commitment to precision and "No MOQ" flexibility. Whether you need rapid prototyping or high-volume assembly, their team is ready to assist. 🚀 Get a Free Quote & DFM Consultation: Visit Sanshun Smart Official Website #PCBA Assembly, #Supply Chain Optimization, #Electronics Manufacturing, #China Sourcing #Sanshun Smart0 Bình luận 1 Chia sẻ 2676 Lượt xem - Some China PCBA manufacturers differentiate themselves by focusing on engineering-driven manufacturing rather than pure price competition. Companies like Sanshun Smart emphasize close collaboration between engineering and production teams, enabling smoother transitions from prototype to volume manufacturing.

By integrating PCB assembly, component sourcing, and testing under one roof, such manufacturers help global clients maintain quality consistency while scaling production.

Learn more about how an experienced China PCBA manufacturer supports complex electronics projects at

https://sanshunsmart.com/

Some China PCBA manufacturers differentiate themselves by focusing on engineering-driven manufacturing rather than pure price competition. Companies like Sanshun Smart emphasize close collaboration between engineering and production teams, enabling smoother transitions from prototype to volume manufacturing. By integrating PCB assembly, component sourcing, and testing under one roof, such manufacturers help global clients maintain quality consistency while scaling production. 👉 Learn more about how an experienced China PCBA manufacturer supports complex electronics projects at https://sanshunsmart.com/0 Bình luận 0 Chia sẻ 779 Lượt xem - For OEM and ODM project leaders managing complex, multi-model production, this expert-level article explains how PCBA China supports batch consistency, project management, and scalable manufacturing. A practical read for teams planning to move from pilot builds to mass production.

https://www.leenkup.com/read-blog/77225For OEM and ODM project leaders managing complex, multi-model production, this expert-level article explains how PCBA China supports batch consistency, project management, and scalable manufacturing. A practical read for teams planning to move from pilot builds to mass production. https://www.leenkup.com/read-blog/772250 Bình luận 0 Chia sẻ 617 Lượt xem

Xem thêm