Kubota mini-excavators are celebrated for their ability to deliver significant power and precision from a compact footprint. The "magic" behind their impressive performance—their ability to dig, slew, and track simultaneously and smoothly—is not just the engine. It is the sophisticated hydraulic system, and at the core of that system on many Kubota models, you will find a high-precision pump from Nachi.

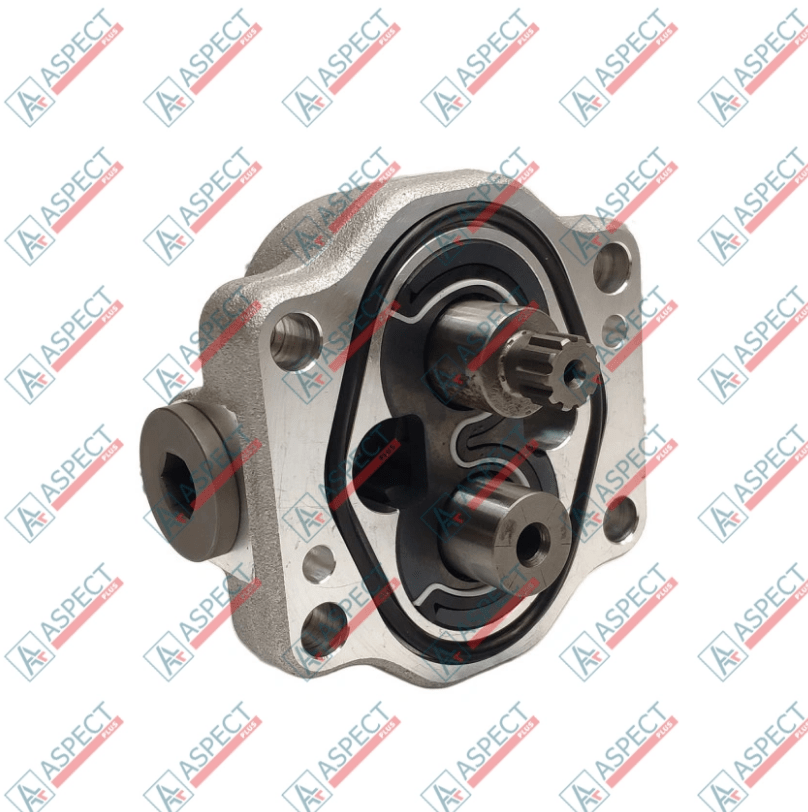

These are not simple, robust gear pumps. They are typically advanced variable-displacement piston pumps. This design is what allows a Kubota to feel so responsive and efficient. But this precision is also its vulnerability. When a Kubota starts to feel "lazy," "weak," or "slow," operators often blame the engine. More often than not, the true culprit is a hydraulic pump that is bleeding pressure and flow internally. Optimizing this pump is not just a matter of simple repair; it requires a specific maintenance philosophy.

The Real Enemies of Nachi Pump Performance

A Nachi pump in a Kubota mini-excavator lives a hard life. The compact design of the machine means the engine bay is crowded, airflow is often limited, and the hydraulic components operate at consistently high temperatures. Failure is rarely spontaneous; it’s a death by a thousand cuts, primarily caused by three factors.

-

Heat: The Silent Killer The hydraulic fluid is the "blood" of the system—it’s a lubricant and a coolant. In the tight confines of a mini-excavator, this fluid gets hot. When the fluid "cooks," its viscosity breaks down. It stops being a slick, protective lubricant and becomes a thin, hot liquid that cannot maintain the critical film between moving parts. This leads directly to metal-on-metal contact.

-

Abrasive Contamination (The Grinding Paste) Over time, microscopic metal particles from the hydraulic motors and cylinders begin to circulate in the fluid. This, combined with any fine dust that gets past the seals, turns the hydraulic fluid into a lapping compound. This abrasive paste scours the most critical, high-precision surfaces within the Nachi pump: the bronze piston shoes and the hardened steel valve plate. This erosion creates internal pathways for oil to leak, which is the root of performance loss.

-

Cavitation and Aeration Cavitation is the sound of the pump starving for fluid. This can be caused by a restricted or collapsing suction hose. Aeration, or air entering the system (often through a bad seal on the pump's input shaft), is just as deadly. In both cases, microscopic bubbles implode under high pressure, which physically pits and chips the pump's internal metal components, leading to rapid and catastrophic failure.

Diagnostics: What the Machine is Telling You

A failing pump speaks a language. A good technician knows how to listen. Before you spend a fortune on a replacement, you must confirm the pump is the problem.

-

The Sound: Listen for a high-pitched, metallic whine that changes in pitch with the engine RPM. This is not a normal hydraulic sound. This is the sound of the pump’s rotating group grinding itself apart or the sound of severe cavitation.

-

The Speed: The machine becomes "lazy." The boom is slow to lift, tracking is weak (especially under load), and the machine can't perform multiple functions at once. This is a classic symptom of lost flow. The pump is leaking internally (bypassing) more fluid than it is delivering to the functions.

-

The Heat: Place your hand near (not on) the pump casing after 30 minutes of operation. If it is significantly hotter than the hydraulic tank or hoses, it’s generating extreme heat from internal friction—a sign it is destroying itself.

-

The Litmus Test: Case Drain Flow: This is the professional's diagnostic. Every piston pump has a case drain line to bleed off normal internal leakage for lubrication. A healthy Nachi pump has a very low, trickling flow from this line. A worn-out pump will have a heavy, gushing flow. By measuring this flow, you can definitively condemn the pump without ever removing it from the machine.

Repair and Maintenance: A Philosophy of Precision

You do not "fix" a high-precision pump like a Nachi. You remanufacture it. This is not a job for a dirty workbench and a hammer.

The Repair Fallacy

The most critical repair process is restoring the mirror-flat surface between the cylinder barrel and the valve plate. This requires a specialized process called "lapping," using diamond compounds on a lapping machine. Without this perfectly flat, sealed surface, the pump will never build full pressure, no matter what new parts you install.

The Parts Trap

When a pump fails, the temptation is to buy a cheap aftermarket "rebuild kit," which usually includes new pistons and a seal kit. This is a false economy. These cheap parts often use inferior bronze alloys and incorrect tolerances. They will fail, often in less than 100 hours, because they cannot withstand the heat and pressure.

The only reliable, long-term repair is a professional remanufacture using genuine Nachi internal components or OEM-quality parts that match the exact material hardness and specifications. This often includes the complete rotating group, valve plate, and bearing set.

The Maintenance Mindset

For mini-excavators, the best maintenance is fluid-centric. Because the machines work in tight, hot environments, the hydraulic fluid must be treated as the system's most important component. Regular hydraulic fluid analysis (oil sampling) is the "blood test" for your machine. It will show you if there is contamination or high levels of wear metals (like copper from the piston shoes) long before the operator ever feels a loss of power.

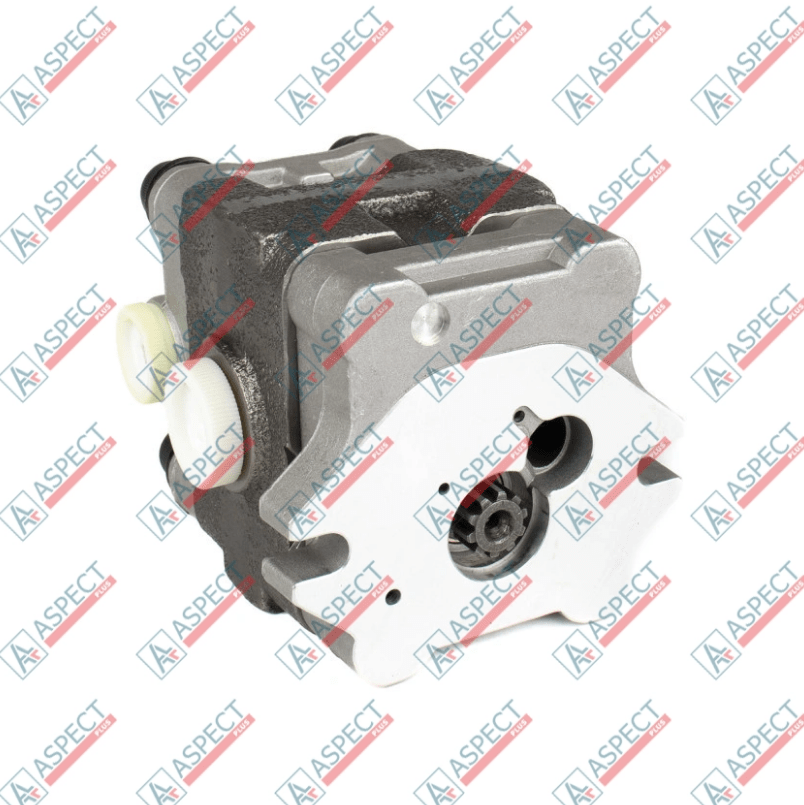

Our company Aspect Plus supplies the high-quality, genuine-spec components required for a professional pump remanufacture. We understand that using the correct parts is the only way to restore a Kubota’s performance to factory-new.

Conclusion

The Nachi pump is the heart of the Kubota mini-excavator's legendary performance. Optimizing it is not about finding the cheapest, quickest fix. It is about a disciplined, precision-based approach to maintenance and repair. The choice is simple: invest in regular fluid analysis and use only high-quality, OEM-spec components for repairs, or prepare for a frustrating and expensive cycle of repeated failures, downtime, and lost productivity.

For expert consultation on hydraulic pump diagnostics and a reliable source for high-quality Nachi spare parts, contact the specialists at Aspect Plus.