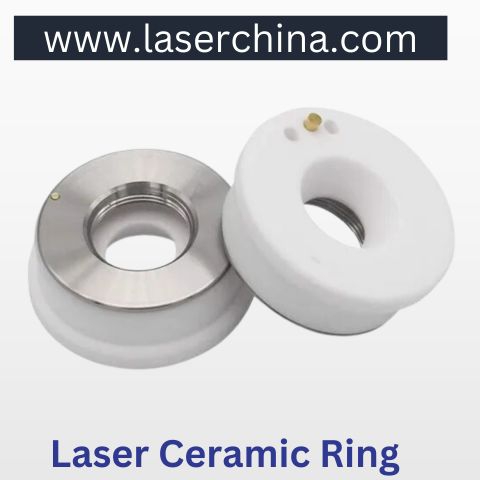

Laser ceramic rings are crucial components in laser cutting systems, playing a pivotal role in ensuring optimal performance and longevity. These rings provide electrical insulation and support to the laser nozzle, contributing to precise cutting and engraving operations. In this detailed guide, we will explore the benefits, types, and applications of laser ceramic rings, providing you with the information needed to enhance your laser system’s performance.

Understanding Laser Ceramic Rings

Laser ceramic rings, also known as laser ceramic insulators or holders, are typically made from high-quality ceramic materials like alumina or zirconia. These materials are chosen for their excellent electrical insulation properties, thermal stability, and mechanical strength. The primary function of a laser ceramic ring is to insulate and support the laser nozzle, ensuring accurate alignment and stable operation.

Types of Laser Ceramic Rings

There are several types of laser ceramic rings, each designed for specific applications and requirements:

-

Standard Ceramic Rings: These rings provide basic insulation and support for the laser nozzle. They are suitable for general cutting and engraving applications where high precision is required.

-

High-Temperature Ceramic Rings: Made from materials that can withstand higher temperatures, these rings are ideal for applications involving prolonged laser operations or higher power lasers.

-

Wear-Resistant Ceramic Rings: These rings are designed to withstand the abrasive effects of the laser cutting process, offering extended durability and reducing the need for frequent replacements.

-

Customized Ceramic Rings: Tailored to specific laser systems and applications, customized ceramic rings provide optimized performance and compatibility with various laser cutting setups.

Benefits of Laser Ceramic Rings

Investing in high-quality laser ceramic rings offers numerous advantages:

-

Enhanced Precision: Laser ceramic rings ensure the precise alignment of the laser nozzle, contributing to accurate and consistent cutting and engraving results. This precision is essential for achieving high-quality finishes on various materials.

-

Improved Durability: High-quality ceramic materials provide excellent resistance to wear and thermal stress, ensuring the longevity of the ceramic ring and reducing the need for frequent replacements.

-

Electrical Insulation: Laser ceramic rings provide effective electrical insulation, protecting the laser system's components from electrical interference and ensuring safe operation.

-

Stable Performance: By supporting the laser nozzle and maintaining its alignment, ceramic rings contribute to the stable and reliable performance of the laser system, enhancing overall productivity.

Applications of Laser Ceramic Rings

Laser ceramic rings are used in a wide range of industries and applications:

-

Manufacturing: In the manufacturing industry, laser ceramic rings are essential for cutting and engraving materials such as metals, plastics, and composites. Their precision and durability make them ideal for producing complex components and products.

-

Automotive Industry: The automotive industry relies on laser ceramic rings for cutting and engraving automotive parts, ensuring the production of high-quality components with exacting specifications.

-

Aerospace: In the aerospace industry, laser ceramic rings are used for cutting and welding lightweight materials, ensuring the production of high-quality components for aircraft and spacecraft.

-

Electronics: The electronics industry uses laser ceramic rings for cutting and engraving circuit boards and other electronic components, ensuring precise and accurate results.

-

Medical Devices: In the medical field, laser ceramic rings are used to manufacture precise medical instruments and equipment, including surgical tools and implants.

Conclusion

Laser ceramic rings are indispensable components in modern laser cutting systems, offering enhanced precision, durability, and stable performance. Whether you are involved in manufacturing, automotive, aerospace, electronics, or medical devices, understanding the benefits and applications of laser ceramic rings can help you achieve superior results. Invest in high-quality laser ceramic rings to unlock the full potential of your laser system and stay ahead in the competitive world of laser technology.