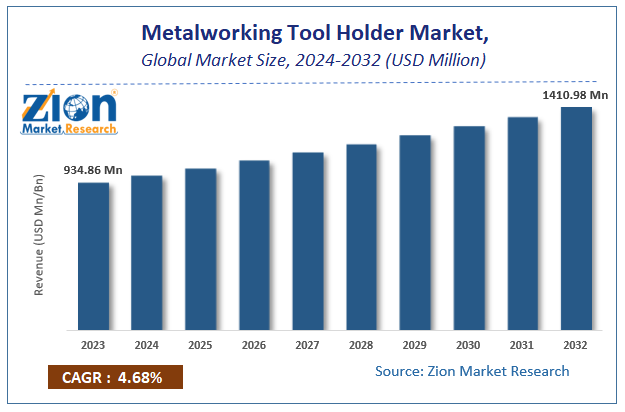

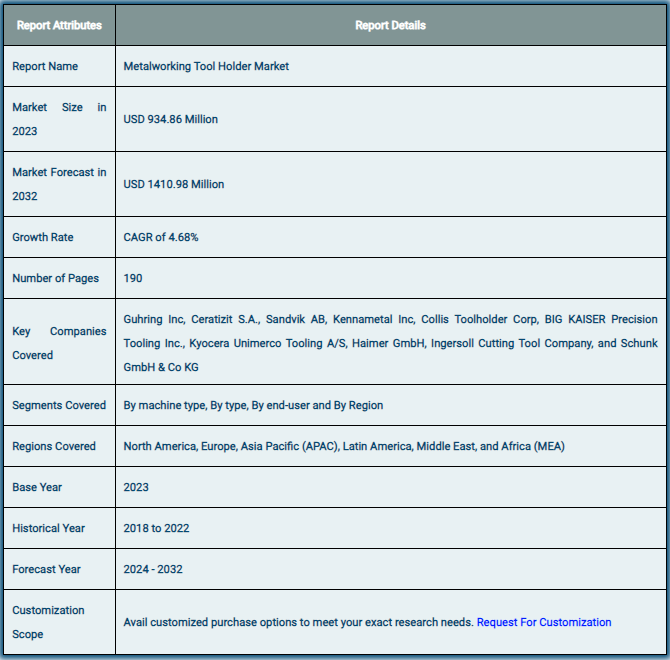

The global metalworking tool holder market was estimated to be worth USD 934.86 million in 2024 and is expected to grow to USD 1410.98 million by the end of 2032, according to a report released by Zion Market Research. Over the course of the projection period, the market is anticipated to rise at a CAGR of 4.68%. The growth prospects, challenges, and effects on demand of the worldwide metalworking tool holder market are examined in this study for the period of forecasting. Additionally, it will support you in navigating and investigating the new opportunities in the Metalworking Tool Holder market.

Introduction

The solvent evaporation market is integral to various industries, particularly pharmaceuticals, chemicals, and food processing. This process is essential for the separation of solvents from solutes, which is crucial in product development, purification, and recovery processes. With increasing demand for efficient and environmentally friendly processes, the solvent evaporation market is witnessing significant growth. This article provides an in-depth analysis of the market, including key drivers, challenges, and future trends.

👇

Overview of the Global Metalworking Tool Holder Market

Tool holders are machined components that are used to shield end milling cutters during the metalworking process. Its goal is to secure the cutting tool as tightly and accurately as possible to avoid product destruction or tool damage due to run-out. It is made up of machine tools with a shank on one end and a short steel bar fastened to them. When connecting high-speed tools to a machine in an efficient and secure manner, the metalworking tool holder is crucial. Metalworking tool holders come in both cylindrical and conical shapes and are mostly utilized in drilling, boring, and milling activities. The tool holder’s properties include balance, power, accuracy, and stiffness.

Growth Factors for the Global Metalworking Tool Holder Market

The market for metalworking tool holders is expanding quickly on a global scale. Increased tool holder usage across a range of end-user industries, including automotive, defense, aerospace, healthcare, and others, as well as growing consumer demand for higher-quality goods, are factors driving the global market’s expansion. The demand for automobiles is being driven by rising urbanization and rapid industrialization in developing nations like China and Japan. This is therefore anticipated to fuel market demand for metalworking tool holders.

The need for these equipment is also being driven up by the industry’s fast expansion due to the rise in car manufacturing and fabricated metals in emerging countries. The market for metalworking tool holders is expanding globally as a result of all these causes. Furthermore, increasing government spending in the healthcare sector in several developing nations, including the US and the UK, is anticipated to provide substantial growth for the global market for metalworking tool holders. However, it is anticipated that the worldwide metalworking tool holder market’s expansion will be constrained by the instability of the economic conditions in developing nations. Moreover, throughout the course of the forecast period, the rise of industry 4.0 and the expanding use of intelligent automation are anticipated to present favorable prospects for the expansion of the worldwide metalworking tool holder market.

Furthermore, there is a significant drop in the global market for metalworking tool holders as a result of the current coronavirus outbreak. The manufacturing sector has been significantly impacted by the government agency’s containment measures and growing concerns about the spread of the coronavirus. The supply chain for tool holders has been disrupted by the COVID-19 pandemic’s prolonged lockdown in several nations, labor shortages, and industry production halts. As a result, during the epidemic, the manufacturing value chain suffered. Nonetheless, throughout the projected period, the metalworking tool holder market is anticipated to grow sustainably due to the relaxation of regulations and the increased attention of major players on preserving the supply chain.

👇

Market Segmentation for Metalworking Tool Holders Worldwide

There are segments in the worldwide metalworking tool holder market according to machine type, type, end-user, and geography.

The global market for metalworking tool holders is segmented based on the type of equipment used, including gear cutting machines, lathe machines, and machining centers.

The type section is divided into hydraulic tool holders, collet chucks, milling chucks, and other categories.

Metalworking tool holders are used by the automotive, aerospace and military, power and energy, and other industries.

Regional Analysis of the Global Metalworking Tool Holder Market

Throughout the projected period, the Asia Pacific region is anticipated to control a large portion of the global market for metalworking tool holders. The market is expanding since there are more metal cutting process industries in this area. Given the expansion of the automobile sector, China is expected to lead the metalworking tool holder market. North America, on the other hand, is anticipated to expand more quickly and have rich prospects for market expansion. The increasing use of automation and IoT in the manufacturing sector, as well as the industry’s rapid expansion in the equipment and machinery manufacturing sector, are some of the reasons driving market growth in this area.

👇

Metalworking Tool Holder Market

What is Solvent Evaporation?

Solvent evaporation involves the removal of solvents from a solution, leaving behind the desired solute. This process is commonly used in laboratories and industrial settings for tasks such as concentration, purification, and solvent recovery. The primary equipment used in solvent evaporation includes rotary evaporators, centrifugal evaporators, and nitrogen blowdown evaporators.

Market Drivers

- Pharmaceutical Industry Growth: The pharmaceutical sector heavily relies on solvent evaporation for drug formulation, purification, and the synthesis of active pharmaceutical ingredients (APIs). As the industry grows, driven by rising healthcare needs and increasing drug development, the demand for efficient solvent evaporation systems increases.

- Environmental Regulations: With stringent environmental regulations focusing on solvent disposal and emissions, industries are turning to solvent recovery and recycling processes. Solvent evaporation systems help meet regulatory requirements by reducing waste and minimizing environmental impact, which is becoming increasingly important across various sectors.

- Advancements in Technology: Continuous innovations in solvent evaporation technology, including automation and energy-efficient systems, are driving market growth. These advancements improve process efficiency, reduce operational costs, and provide more precise control, making solvent evaporation more accessible and appealing to a wide range of industries.

- Demand for High-Purity Products: Industries like biotechnology and food processing require high-purity products, which necessitates effective solvent evaporation. The growing demand for purity in end products is propelling the adoption of advanced solvent evaporation technologies.

Market Challenges

- High Initial Costs: Advanced solvent evaporation systems, particularly those used in industrial applications, can be expensive to purchase and install. These high initial costs can be a barrier for smaller companies or startups with limited budgets.

- Operational Complexity: While technology is advancing, solvent evaporation systems can still be complex to operate and maintain. Proper training and expertise are required to ensure optimal performance and avoid operational errors, which can be a challenge for companies with limited technical resources.

- Energy Consumption: Although energy-efficient models are becoming more common, solvent evaporation processes can still be energy-intensive. Managing energy consumption and costs is a critical concern for companies aiming to improve their sustainability profiles.

- Market Fragmentation: The solvent evaporation market is highly fragmented, with numerous players offering various equipment types and solutions. This fragmentation can make it challenging for end-users to identify the best.

Key Players in the Market

Several companies are leading the metalworking tool holder market, offering a wide range of products and solutions:

- Sandvik Coromant: A global leader in metal cutting tools, Sandvik Coromant offers a comprehensive range of tool holders designed for various applications, including turning, milling, and drilling.

- Kennametal: Known for its innovative cutting tools and tool holders, Kennametal serves industries such as aerospace, automotive, and energy, providing high-performance solutions for complex machining tasks.

- Schunk: Specializing in clamping technology, Schunk offers a wide array of tool holders that ensure maximum precision and stability in machining processes.

- Haimer: Haimer is a prominent player in the tool holding sector, offering shrink-fit holders, collet chucks, and balancing systems that cater to high-precision applications.

- MST Corporation: MST is known for its high-quality tool holders and modular systems, providing solutions that enhance flexibility and efficiency in machining operations.

Regional Insights

- North America: The metalworking tool holder market in North America is driven by strong demand from the aerospace and automotive industries. The presence of advanced manufacturing facilities and a focus on technological innovation contribute to the region’s market growth.

- Europe: Europe is a significant market for tool holders, with countries like Germany, Italy, and France being key players in the manufacturing sector. The region’s emphasis on precision engineering and high-quality production standards drives the demand for advanced tool holder solutions.

- Asia-Pacific: The Asia-Pacific region is experiencing rapid growth in the metalworking tool holder market, driven by the expanding manufacturing sectors in China, Japan, and India. The region’s growing industrial base and increasing investments in automation are key factors fueling market growth.

- Latin America and Middle East & Africa: These regions are gradually adopting advanced manufacturing technologies, leading to a growing demand for metalworking tool holders. However, the market in these regions is still developing, with potential for future growth as industries modernize.

Future Trends

- Automation and Industry 4.0: The integration of automation and smart technologies in manufacturing is expected to drive the demand for tool holders that are compatible with Industry 4.0 standards. These tool holders will need to be equipped with sensors and connectivity features to enable real-time monitoring and data analysis.

- Sustainability and Energy Efficiency: As sustainability becomes a priority for manufacturers, there will be a growing demand for tool holders that contribute to energy-efficient machining processes. Lightweight and durable materials, as well as designs that minimize energy consumption, will be key trends in the market.

- Additive Manufacturing Integration: The rise of additive manufacturing (3D printing) is influencing the metalworking industry. Tool holders that can accommodate hybrid machining processes, combining subtractive and additive techniques, will become increasingly important.

- Customization and Modular Solutions: The demand for customized and modular tool holder systems is expected to grow as manufacturers seek flexible solutions that can adapt to various machining tasks. This trend will drive innovation in tool holder design and functionality.

Conclusion

The metalworking tool holder market is poised for significant growth, driven by advancements in machining technologies, increasing demand for precision, and the expansion of key industries like automotive and aerospace. While challenges such as high costs and intense competition exist, the market offers substantial opportunities for innovation and development. Companies that focus on technological advancements, customization, and sustainability will be well-positioned to lead in this evolving market.

Contact Us:

Zion Market Research

USA/Canada Toll Free: 1 (855) 465–4651

Newark: 1 (302) 444–0166

Web: https://www.zionmarketresearch.com/

Blog: https://zmrblog.com/

Browse other trend reports:

https://www.linkedin.com/pulse/bread-softeners-market-size-share-trends-growth-qzwmf

https://www.linkedin.com/pulse/signals-intelligence-sigint-market-size-share-trends-8hdrf

https://www.linkedin.com/pulse/solvent-evaporation-market-size-share-trends-growth-zekef

https://www.linkedin.com/pulse/metalworking-tool-holder-market-size-share-industry-hf5qf

https://www.linkedin.com/pulse/solar-silicon-wafer-market-size-share-trends-growth2024-2032-pcsuf