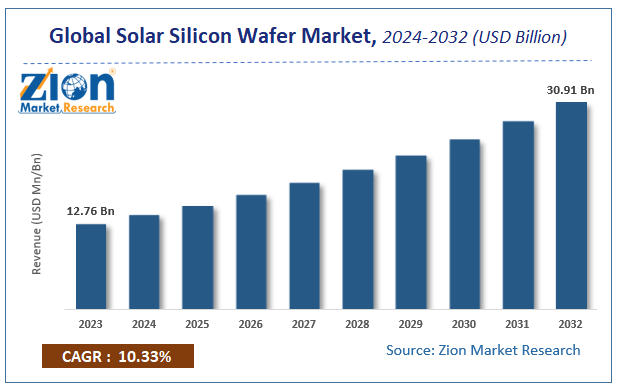

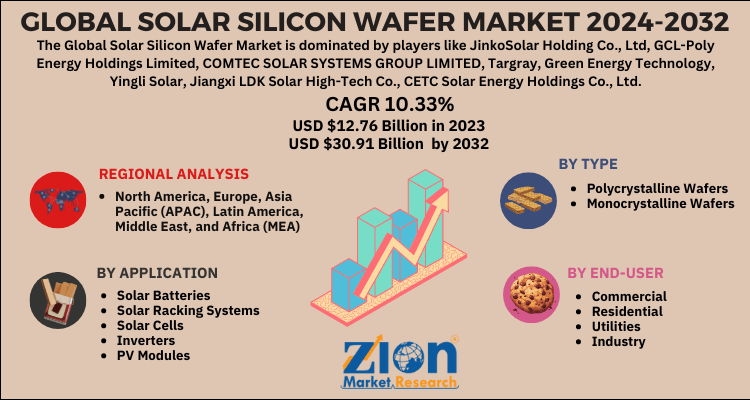

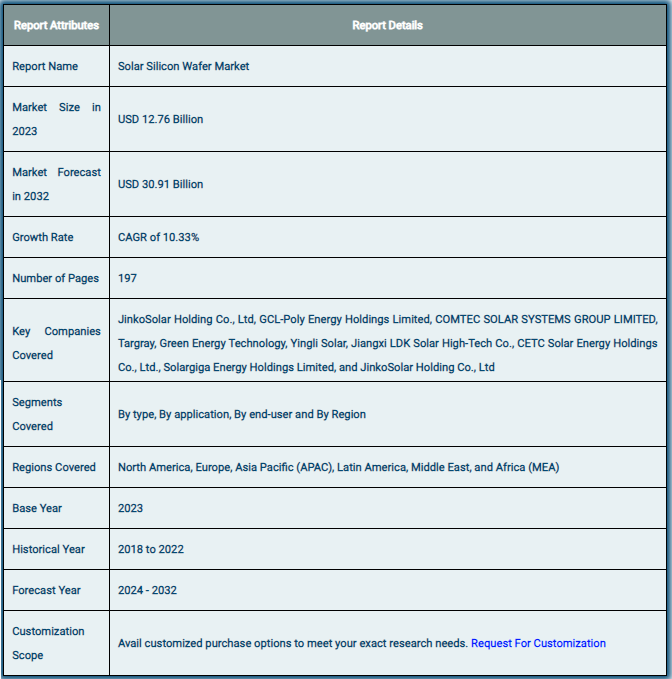

The global solar silicon wafer market was estimated to be worth USD 12.76 billion in 2024 and is expected to grow to USD 30.91 billion by the end of 2032, according to a report released by Zion Market Research. Over the course of the projection period, the market is anticipated to expand at a CAGR of 10.33%. The growth factors, challenges, and effects on demand for the worldwide solar silicon wafer market are examined in this study for the period of forecasting. Additionally, it will support exploration and navigation of the emerging opportunities in the solar silicon wafer market.

Introduction

The solar silicon wafer market is a critical segment of the global renewable energy industry. As the demand for clean and sustainable energy sources continues to rise, solar energy has become a leading alternative to traditional fossil fuels. Silicon wafers, the key components in photovoltaic (PV) cells, are central to this growth. This article explores the current state of the solar silicon wafer market, highlighting key drivers, challenges, and future trends.

👇

Overview of the Global Solar Silicon Wafer Market

A solar wafer is a thin slice of crystalline silicon that serves as a substratum for microeconomic devices (semiconductor). It is utilized in photovoltaics to create integrated circuits for the production of solar cells. The ability of such wafers to directly convert solar radiation into electrical energy is crucial for photovoltaic production and the PV power generation system. High-purity silicon material is used to shape the wafer into a circular disk for use in solar system applications.

Growth Factors for the Global Solar Silicon Wafer Market

Some of the main drivers driving the growth of the worldwide solar silicon wafer market are the rise in energy consumption, the preference for clean energy, and the electrification of rural areas. The semiconductor material that is utilized in solar cells the most frequently is silicon. Furthermore, the second most readily available substance on Earth is oxygen.

Solar silicon wafers combine cheap cost, excellent efficiency, and a long lifespan. Currently, photovoltaic solar cells are made of a variety of silicon materials, including monocrystalline, polycrystalline, and amorphous silicon. Furthermore, silicon nitride is progressively taking the position of titanium dioxide as an anti-reflection coating because of its superior surface passivation properties.

It aids in keeping carriers from recombining at the solar cells’ surface. Furthermore, solar cells are much more peacefully subject to the stringent standards for quality control and cleanliness in semiconductor manufacture. Consequently, printed silicon solar cells are produced by the majority of large-scale commercial sun cell factories. The global market is expanding as a result of all these factors. Additionally, the market is growing due to a number of causes, including the development in solar installations in both the commercial and residential sectors and the fast growing automobile industry, which uses silicon wafers extensively in electric vehicles.

Additionally, during the course of the forecast period, there should be various chances for the expansion of the worldwide solar silicon wafer market due to technical improvements and the growing emphasis on the usage of renewable energy sources, both of which drive demand for solar silicon wafers. However, silicon wafer panels are more expensive to manufacture and install than thin-film photovoltaic panels, which could impede the expansion of the worldwide solar silicon wafer market.

There has been a decline in the sales of solar silicon wafers as the effects of the Covid-19 epidemic on the semiconductor industry remain unclear. This is because to changes in supply and demand, price patterns, and supplier dynamics brought about by the stringent movement restrictions and total lockdown regulations enforced by the governments of numerous nations worldwide. Additionally, during the pandemic, the closure of industry manufacturing facilities and restrictions on employee mobility had an impact on the expansion of the worldwide market for solar silicon wafers.

Market Segmentation for Solar Silicon Wafers Worldwide

Type, application, end-user, and geography are the classifications used to categorize the global solar silicon wafer market.

The global market for solar silicon wafers is divided into two segments based on the type: polycrystalline and monocrystalline wafers.

Due to its extremely low waste production, the polycrystalline sector of the market is anticipated to hold the largest share.

The global market is divided into solar batteries, solar racking systems, solar cells, inverters, and PV modules according to the application.

The market is expected to be dominated by the PV module among them due to the increasing demand for large-size wafers.

There are four categories under the end-user segment: utilities, industries, residential, and commercial.

Due of the government’s extensive installations, the utility sector is thought to hold the largest share.

Global Market for Solar Silicon Wafers: Regional Evaluation

Over the course of the forecast period, North America is anticipated to hold the greatest share of the global market for solar silicon wafers. The region’s rise is ascribed to the existence of significant companies, efficient marketing analytics tools, rising solar silicon wafer demand, and cutting-edge technology. However, because of the region’s booming vehicle sector, government measures promoting the use of solar silicon wafers, and rising demand for clean energy, Asia Pacific is predicted to grow at the quickest rate.

What are Solar Silicon Wafers?

Solar silicon wafers are thin slices of highly purified silicon that serve as the substrate for solar cells. These wafers convert sunlight into electricity through the photovoltaic effect, making them essential in the production of solar panels. There are two primary types of silicon wafers used in the solar industry: monocrystalline and polycrystalline wafers. Monocrystalline wafers are known for their higher efficiency and longevity, while polycrystalline wafers are more cost-effective.

Market Drivers

- Increasing Demand for Renewable Energy: As global energy needs grow and environmental concerns rise, governments and industries are turning to renewable energy sources. Solar power, in particular, is seen as a viable solution to reduce carbon emissions and achieve sustainability goals. This increasing demand for solar energy directly drives the growth of the solar silicon wafer market.

- Technological Advancements: Continuous innovations in solar cell technology, such as the development of high-efficiency cells and bifacial panels, are fueling the demand for advanced silicon wafers. Improved manufacturing techniques are also reducing the cost of production, making solar energy more accessible.

- Government Incentives and Policies: Many governments are implementing policies and offering incentives to promote the adoption of solar energy. Subsidies, tax breaks, and renewable energy mandates are encouraging investments in solar power infrastructure, which in turn boosts the demand for solar silicon wafers.

- Cost Reduction in Solar Energy: The declining cost of solar panels, driven by economies of scale and technological advancements, has made solar energy more competitive with traditional energy sources. As the cost of solar energy continues to fall, the demand for silicon wafers is expected to rise further.

Market Challenges

- Supply Chain Disruptions: The production of silicon wafers relies on a complex global supply chain. Disruptions in the supply of raw materials, such as high-purity silicon, can lead to delays and increased costs. Geopolitical tensions, trade restrictions, and natural disasters can also impact the supply chain.

- Environmental Concerns in Manufacturing: The production of silicon wafers is energy-intensive and involves the use of hazardous chemicals. While solar energy is environmentally friendly, the manufacturing process for silicon wafers has raised concerns about its environmental impact. Companies are under pressure to adopt greener manufacturing practices.

- Competition from Alternative Technologies: While silicon wafers dominate the solar market, alternative technologies such as thin-film solar cells and perovskite solar cells are gaining traction. These technologies offer potential advantages in terms of cost, efficiency, and flexibility, posing a competitive threat to traditional silicon wafers.

- Price Volatility: The solar silicon wafer market is subject to price fluctuations due to changes in supply and demand dynamics. Factors such as overproduction, shifts in government policies, and competition from other materials can lead to price volatility, affecting profitability for manufacturers.

Key Players in the Market

Several companies are leading the solar silicon wafer market, focusing on innovation and scaling production:

- LONGi Green Energy Technology: One of the largest manufacturers of monocrystalline silicon wafers, LONGi is a key player in the global solar industry, known for its high-efficiency products.

- Wacker Chemie AG: A leading supplier of polysilicon, Wacker Chemie provides high-purity silicon for wafer production, serving both the semiconductor and solar industries.

- GCL-Poly Energy Holdings Limited: A major player in the production of polycrystalline silicon wafers, GCL-Poly is a key supplier to the global solar market.

- JinkoSolar Holding Co., Ltd.: JinkoSolar is a global leader in solar module manufacturing and also produces high-quality silicon wafers for its PV products.

- SUMCO Corporation: Known for its expertise in semiconductor wafers, SUMCO is also a significant supplier of solar-grade silicon wafers, catering to the growing demand for solar energy.

Regional Insights

- Asia-Pacific: The Asia-Pacific region, particularly China, dominates the solar silicon wafer market. China is the largest producer and consumer of solar silicon wafers, driven by its vast solar energy infrastructure and manufacturing capabilities. Other key markets in the region include India, Japan, and South Korea, where solar energy adoption is rapidly increasing.

- North America: In North America, the solar silicon wafer market is driven by strong demand for renewable energy, particularly in the United States. Government initiatives, such as the extension of the Investment Tax Credit (ITC), are boosting investments in solar power projects, leading to increased demand for silicon wafers.

- Europe: Europe is a significant market for solar energy, with countries like Germany, Spain, and the Netherlands leading the way in solar installations. The region’s commitment to reducing carbon emissions and increasing renewable energy capacity is driving the demand for solar silicon wafers.

- Middle East & Africa: The Middle East & Africa region iWs witnessing growing interest in solar energy as countries seek to diversify their energy sources and reduce reliance on fossil fuels. Large-scale solar projects in countries like the UAE, Saudi Arabia, and South Africa are contributing to the demand for silicon wafers.

Future Trends

- Efficiency Improvements: Ongoing research and development efforts are focused on improving the efficiency of solar cells. Higher efficiency wafers, such as those used in tandem solar cells, are expected to become more prevalent, driving the market forward.

- Sustainable Manufacturing Practices: As environmental concerns gain prominence, the industry is likely to adopt more sustainable manufacturing practices. This includes reducing energy consumption, recycling waste materials, and minimizing the use of hazardous chemicals in wafer production.

- Expansion of Solar Energy Storage: The integration of solar energy with storage solutions, such as batteries, is expected to increase. This trend will boost the demand for solar panels and, consequently, for silicon wafers.

- Growth of Distributed Solar: The rise of distributed solar energy systems, including residential and commercial rooftop installations, will create new opportunities for the solar silicon wafer market. Smaller, decentralized solar installations will drive demand for customized wafer solutions.

Conclusion

The solar silicon wafer market is poised for continued growth, driven by the global shift towards renewable energy and advancements in solar technology. While challenges such as supply chain disruptions and competition from alternative technologies exist, the market offers significant opportunities for innovation and expansion. Companies that focus on efficiency, sustainability, and technological advancements will be well-positioned to lead in this dynamic market.

Contact Us:

Zion Market Research212

USA/Canada Toll Free: 1 (855) 465–4651

Newark: 1 (302) 444–016611\s

Web: https://www.zionmarketresearch.com/

Blog: https://zmrblog.com/

Browse other trend reports:

https://www.linkedin.com/pulse/bread-softeners-market-size-share-trends-growth-qzwmf

https://www.linkedin.com/pulse/signals-intelligence-sigint-market-size-share-trends-8hdrf

https://www.linkedin.com/pulse/solvent-evaporation-market-size-share-trends-growth-zekef

https://www.linkedin.com/pulse/metalworking-tool-holder-market-size-share-industry-hf5qf

https://www.linkedin.com/pulse/solar-silicon-wafer-market-size-share-trends-growth2024-2032-pcsuf