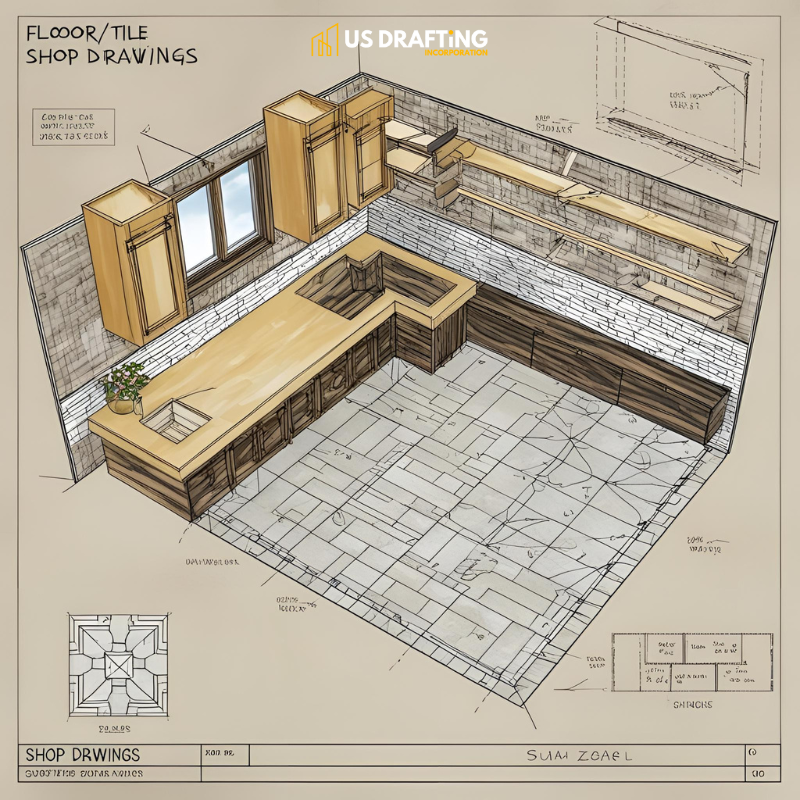

In the construction industry, precision is crucial to ensuring a project’s success. One of the key tools that help achieve accuracy and efficiency is shop drawings, particularly for floors and tiles. These detailed technical drawings provide a clear representation of how flooring materials should be installed, ensuring alignment with design specifications, structural requirements, and aesthetic expectations.

By offering precise measurements, material details, and installation guidelines, shop drawings help contractors, architects, and installers avoid costly mistakes, reduce material waste, and maintain quality standards.

What Are Shop Drawings?

Shop drawings are detailed technical drawings that show how different parts of a building or product will be made, assembled, or installed. They are used in construction and manufacturing to ensure that everything is built correctly and according to the design.

These drawings provide more details than general design plans. They include precise measurements, materials, and installation instructions. Contractors, fabricators, and engineers use shop drawings to guide their work. For example, shop drawings are made for structural steel, windows, doors, cabinets, electrical systems, and plumbing.

Unlike architectural drawings, which show the overall design of a project, shop drawings focus on specific parts. They help identify any issues before construction begins, reducing errors and saving time and money. If changes are needed, shop drawings allow adjustments to be made before the actual work starts.

Shop drawings are usually created by manufacturers, suppliers, or subcontractors. They must be reviewed and approved by architects or engineers before construction. This ensures that they meet project requirements and building codes.

In summary, shop drawings play a crucial role in construction and manufacturing. They provide a clear and detailed guide for workers, helping ensure accuracy and efficiency. With proper shop drawings, projects can be completed smoothly and with fewer mistakes.

Importance of Shop Drawings for Floors and Tiles

Shop drawings are essential for flooring and tile installation. They provide detailed plans that help ensure accuracy, efficiency, and quality in a construction project. These drawings show the exact layout, measurements, and patterns of tiles and flooring materials, preventing errors and reducing waste.

One of the biggest advantages of shop drawings is precision. Without them, installers might face problems like misalignment, incorrect cuts, or uneven surfaces. With detailed plans, workers can follow a clear guide, making the installation process faster and smoother.

Shop drawings also help with material estimation. They show the exact number of tiles or flooring materials needed, avoiding shortages or excess purchases. This not only saves money but also reduces material waste, making the project more cost-effective.

Coordination between different teams is another benefit. Architects, designers, and contractors can review and approve shop drawings before installation begins. This prevents misunderstandings and ensures that the final look matches the design vision.

Additionally, shop drawings help in complex tile patterns and custom flooring designs. Whether it's a mosaic design or a specific tile arrangement, the drawings act as a blueprint to achieve the desired outcome.

Key Components of Shop Drawings for Floors and Tiles

Shop drawings for floors and tiles are detailed technical drawings used in construction projects. They help ensure accuracy in material placement, design, and installation. Here are the key components of these drawings:

-

Floor Layout Plan

This plan shows the overall floor design, including dimensions, tile patterns, and material specifications. It ensures that tiles are placed correctly and match the design intent. -

Material Specifications

Shop drawings list the type, size, color, and finish of tiles. They may also include details about adhesives, grout, and sealants to be used in the installation. -

Tile Patterns and Orientation

The drawings indicate tile layouts, such as straight, diagonal, or herringbone patterns. They also show alignment and cutting details for a seamless finish. -

Expansion Joints and Spacing

Expansion joints are necessary to prevent cracks due to movement or temperature changes. The drawings specify joint locations and widths. -

Edge and Transition Details

These details show how tiles meet walls, doorways, or different flooring materials. They include baseboards, trim, and thresholds to ensure a smooth transition. -

Installation Notes and Instructions

Instructions guide installers on proper techniques, including waterproofing, leveling, and required subfloor preparation. -

Site Measurements and Verification

Exact site measurements ensure that tiles fit correctly, avoiding errors during installation.

Well-prepared shop drawings help construction teams work efficiently, reducing mistakes and material waste.

The Shop Drawing Process in Construction

Shop drawings are detailed drawings used in construction to show how different parts of a building will be made and installed. They provide more information than the general construction plans and are created by contractors, fabricators, or suppliers. These drawings help ensure that everything fits together properly before actual construction begins.

The shop drawing process starts with the contractor or supplier preparing the drawings based on the design plans. These drawings include measurements, materials, and specific details about each component. Once completed, the drawings are sent to the architect or engineer for review. They check for accuracy and ensure that the drawings follow the project’s design and safety standards.

If there are any mistakes or necessary changes, the architect or engineer will mark them and return the drawings for revisions. This process may happen multiple times until the drawings are approved. After approval, the shop drawings guide the workers in fabricating and installing the materials correctly.

Shop drawings are crucial in construction because they help avoid mistakes, reduce delays, and improve coordination between different teams. They ensure that everything is built according to plan, making the construction process smoother and more efficient.

The End

Shop drawings for floors and tiles are an essential component of modern construction projects, ensuring accuracy, efficiency, and high-quality results. These detailed technical drawings provide precise layouts, material specifications, and installation guidelines, helping contractors and installers avoid costly errors, reduce material waste, and streamline the construction process.

By improving coordination among architects, designers, and builders, shop drawings ensure that the final outcome aligns with the intended design and meets structural and aesthetic requirements.

Ultimately, investing time in well-prepared shop drawings leads to smoother installations, cost savings, and a more durable, visually appealing finished product.