Step A involves melting the raw materials at a temperature of 930-960°C, allowing them to cool to 710-760°C, and then allowing them to stand for 5-10 minutes; step B involves melting the raw materials at a temperature of 930-960°C, allowing them to cool to 710-760°C, and then allowing them to stand for 5-10 minutes; step C involves melting the raw materials at a temperature of 930-960°C, allowing them to stand for

The temperature of the refining and degassing treatment in step B is 690-730°C.

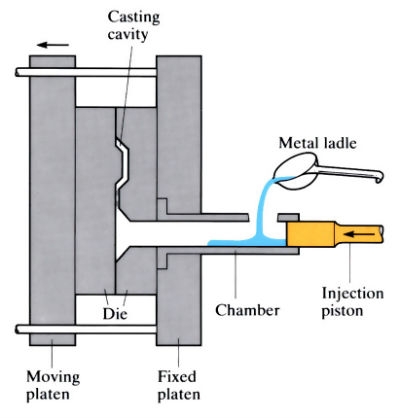

In step C, the temperature of the molten aluminum alloy is 640-680°C, and the molten aluminum alloy is poured into the production cavity through a double-layer runner for die-casting molding, with the preheating temperature of the production cavity being 180-220°C.

In step C, the temperature of the mold preheat treatment is 500-550°C, and then the mold temperature is reduced to 300-350°C, and the temperature is maintained for 2-4 hours;

In step D, the mold is heated to 350-400°C for 0.3-0.6h, then heated to 700-850°C in two stages in a protective atmosphere, and cooled to 150-160°C after oil quenching. The mold is then heated to 450-500°C for 0.5-1.5h, tempering, and heat preservation.

2. A die for improving the internal structure of aluminum alloy stamping profiles, as defined in claim 1, characterized by the following features:

In step A, the chemical composition of the mold is composed of the elements listed below in order of weight percentage:Cr: 6%-9%, Si: 4.5%-5.5%, Cu: 1.3%-1.7%, Fe:6%-8%, Mn:0.25%-0.30%, Zn:0.45%-0.55%, Mg:0.12%-0.20%, Ni:0.125%-0.15%, Sn: 0.13%-0.17%, Ti: 0.13%-0.17%, Pb: 0.13%-0.17%, Al: the remainder.

3. A die for improving the internal structure of aluminum alloy stamping profiles, as defined in claim 1, characterized by the following characteristics:

In step A, the chemical composition of the mold is composed of the elements listed below in order of weight percentage:Cr: 7.5%, Si: 5%, Cu: 1.5%, Fe: 7%, Mn: 0.27%, Zn: 0.50%, Mg: 0.16%, Ni: 0.14%, Sn: 0.15%, Ti: 0.15%, Pb: 0.15%, Al: 0.15%, the rest is Al.

Die Casting Die for HPDC Process Created by Become a master of CAD Design.

Die Casting - Permanent Mold Casting Processes.

Building a Permanent "Diecasting" Molding Press | Spareroom Competition Entry 2019

Casting Parts - Die casting - Part 2

Cast aluminum parts are widely used and stored