Computer Numerical Control (CNC) machines have transformed modern manufacturing by offering precision, efficiency, and versatility across a variety of materials. Whether working with wood, metal, or plastic, CNC machines allow operators to achieve intricate designs and flawless finishes that manual tools simply cannot match. Understanding how does a CNC machine work is essential for businesses, hobbyists, and students who want to harness this technology for creative and industrial purposes. Let’s explore how CNC machines function across different materials and what makes them indispensable in today’s production environments.

CNC technology operates by using pre-programmed software to dictate the movement of tools along specific paths. This eliminates human error and ensures repeatable accuracy, even on complex projects. The process begins with creating a digital design using CAD (Computer-Aided Design) software, which is then translated into machine language that guides the CNC equipment. Whether shaping delicate wooden furniture, fabricating robust metal parts, or carving detailed plastic components, CNC machines bring precision and consistency to every job.

CNC Machines and Woodworking: Precision in Craftsmanship

When it comes to woodworking, CNC machines provide an unmatched level of detail and repeatability. In traditional woodworking, achieving uniform cuts, intricate patterns, and symmetrical designs can be a time-consuming task that requires significant skill. With CNC machines, operators can design complex wooden pieces using CAD software, and the machine executes these designs with precision. The cutting tools in a CNC router move along the X, Y, and Z axes to carve, cut, drill, and engrave wood with incredible accuracy, creating furniture, cabinetry, signs, and decorative pieces with ease.

The beauty of how does a CNC machine work in woodworking lies in its ability to handle both softwoods and hardwoods effortlessly. CNC routers can work continuously for hours, producing large quantities of identical parts without fatigue. Additionally, CNC technology minimizes waste by optimizing the layout of cuts on wood panels, helping businesses save material costs. Whether for small custom projects or mass production, CNC machines empower woodworkers to focus on creativity and design, leaving the precision work to the technology.

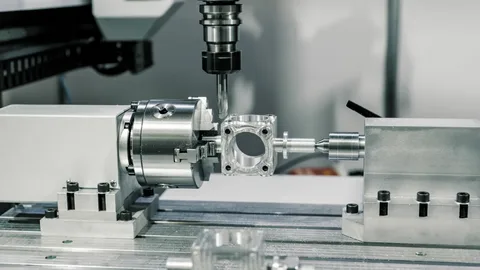

CNC Machines in Metalworking: Strength and Accuracy

Metalworking presents a unique challenge due to the toughness of the materials involved. CNC machines address this challenge through robust construction and powerful cutting tools capable of machining metals such as aluminum, steel, brass, and titanium. The process starts with a CAD model, which is converted into G-code instructions that guide the CNC lathe, mill, or plasma cutter. The machine executes these commands to mill, drill, cut, or shape metal parts to exact specifications. This level of precision is critical in industries such as aerospace, automotive, and medical device manufacturing, where accuracy can directly impact safety and performance.

One of the remarkable aspects of how does a CNC machine work with metal is its ability to maintain tight tolerances and produce complex geometries that would be difficult or impossible to achieve manually. CNC machines can create intricate features such as threads, slots, holes, and contours in metal components while ensuring consistency across large production runs. Additionally, modern CNC metalworking machines can operate at high speeds with coolant systems that reduce heat and wear on cutting tools, further enhancing productivity and tool life.

CNC Machines and Plastics: Versatility and Speed

Plastics are widely used across many industries due to their lightweight nature, corrosion resistance, and ease of forming. CNC machines excel at machining various plastics, including acrylic, polycarbonate, nylon, and PVC. The process of how does a CNC machine work with plastic is similar to that of wood or metal. The operator creates a digital design, generates a toolpath, and loads it into the machine. CNC routers, mills, or laser cutters then shape the plastic material according to the programmed instructions. The machine’s high-speed cutting tools ensure clean edges and precise dimensions, which are vital for applications in electronics, signage, and packaging.

Another advantage of using CNC machines for plastics is the ability to produce prototypes and finished parts quickly and efficiently. Plastics are often used in rapid prototyping due to their ease of machining, and CNC technology ensures that designs can be adjusted and iterated upon without extensive downtime. Furthermore, CNC machining produces minimal waste when cutting plastic materials, as the software can nest parts efficiently within the raw sheet. This makes CNC machining a cost-effective solution for plastic fabrication, from small custom orders to large-scale production.

The Core Components That Make CNC Machines Work

Understanding how does a CNC machine work requires a closer look at the essential components that drive its functionality. The core of any CNC machine includes the machine frame, the motor-driven axes, the spindle (which holds the cutting tool), and the control system. The frame provides stability, while the motors and ball screws move the cutting tool along precise paths. The spindle rotates the tool at controlled speeds, enabling the machine to cut, drill, or engrave the material as programmed. Each part of the system must work in harmony to achieve the desired outcome, ensuring accuracy and repeatability.

Equally important is the CNC control system, which acts as the brain of the machine. This system interprets the G-code generated from the CAD/CAM software and converts it into electrical signals that drive the motors. Operators input parameters such as tool type, feed rate, spindle speed, and cutting depth, and the CNC system manages these variables in real-time. Thanks to advancements in automation, modern CNC machines also feature sensors, touch probes, and feedback loops that enhance accuracy and prevent errors during machining. These components collectively demonstrate how does a CNC machine work to transform digital designs into physical reality.

Advantages of CNC Machining Across Materials

The primary advantage of CNC machining—whether working with wood, metal, or plastic—is its ability to deliver high precision with minimal human intervention. Once programmed, a CNC machine can produce part after part with consistent quality, making it ideal for industries where accuracy is critical. For example, in the automotive industry, CNC machines ensure that metal engine components meet exact specifications, while in furniture making, they allow for flawless wooden joints and decorative inlays. The versatility of CNC machines also means they can switch between materials with minimal setup changes, providing manufacturers with flexibility in production.

Another key benefit tied to how does a CNC machine work is its efficiency and cost-effectiveness. CNC machines reduce the need for manual labor, lowering production costs and shortening lead times. They also minimize material waste by optimizing cutting paths, which is crucial in industries where raw materials are expensive. Additionally, CNC machining supports customization and small-batch production without the need for costly tooling changes. Whether fabricating a single custom piece or producing thousands of identical parts, CNC machines provide a reliable, scalable solution that meets the demands of modern manufacturing.