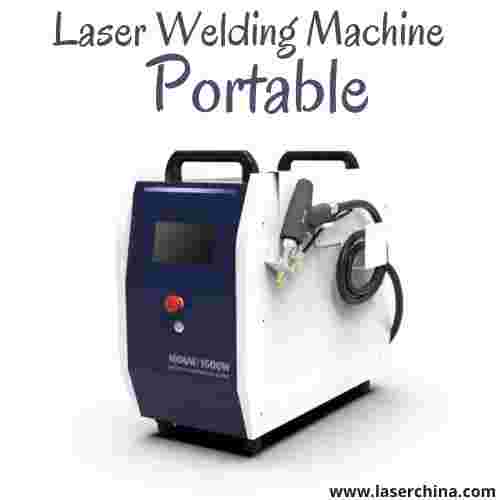

The global demand for precise, fast, and reliable welding technologies has shifted the focus toward laser-based solutions. Among these innovations, the laser welding machine portable has transformed how industries manage welding operations. Unlike conventional methods that require large stationary setups, a portable system offers mobility, flexibility, and efficiency without compromising welding quality. Businesses in automotive, aerospace, electronics, and metal fabrication are increasingly adopting this technology to meet production standards and reduce operational complexity.

Evolution of Welding and the Rise of Portability

For decades, welding was carried out using arc welding, TIG, or MIG setups that demanded large machinery and skilled operators. While effective, these methods came with limitations—restricted mobility, extensive consumables, and heat-affected zones that often required post-processing.

The development of laser welding machines portable changed this landscape. By harnessing focused laser beams, these devices produce deep penetration with minimal distortion. Portability further allows manufacturers and workshops to carry out tasks in confined spaces or directly on large structures without relocating components. This flexibility makes it a valuable investment across different industrial sectors.

How a Portable Laser Welding Machine Works

A laser welding machine portable generates a high-intensity laser beam that melts and fuses metal surfaces together. The process relies on precise control of heat and energy density, which ensures strong joints with minimal defects. Unlike conventional welding, which requires filler materials in many cases, laser welding often eliminates this step, making the process cleaner and more efficient.

The portable versions are designed with ergonomic handheld attachments and lightweight power units, allowing operators to move freely. This adaptability makes them especially useful for fieldwork, maintenance tasks, or projects involving large, immovable components.

Industrial Applications of Portable Laser Welding Machines

-

Automotive Manufacturing

The automotive sector relies heavily on precision and durability. From car body assembly to battery components in electric vehicles, a laser welding machine portable enables consistent welds with minimal deformation. Its portability ensures that welding can be done directly on the production line without shifting heavy parts. -

Aerospace and Aviation

Aircraft components demand the highest reliability. Portable laser welding provides manufacturers with the capability to carry out high-strength welds on aluminum, titanium, and advanced alloys used in aircraft structures. The ability to perform precise welds in restricted or complex geometries makes it indispensable. -

Medical Equipment Fabrication

In the medical field, precision is crucial. Devices such as surgical tools, implants, and stainless-steel assemblies benefit from the clean and contamination-free welds produced by portable laser machines. Their mobility also supports on-site repairs in hospital facilities. -

Electronics and Micro-Components

Electronic devices often require welding of extremely small parts. Portable laser welding ensures accuracy in fusing delicate components, such as battery connectors, sensors, and micro-circuits, without causing damage to surrounding materials. -

Metal Fabrication and Repair

Workshops and repair industries make extensive use of laser welding machines portable for tasks ranging from fixing machinery to fabricating new metal structures. Its ability to weld dissimilar metals broadens its use beyond standard steel and aluminum applications.

Benefits Driving Industry Adoption

The rising popularity of laser welding machine portable systems is linked to specific operational advantages:

-

Precision and Clean Finish: Produces minimal spatter and requires little to no finishing.

-

Reduced Heat-Affected Zones: Ensures less distortion and stronger welds.

-

Mobility and Flexibility: Lightweight design enables use in varied environments.

-

Material Versatility: Suitable for metals like stainless steel, titanium, aluminum, and more.

-

Lower Maintenance: Fewer consumables compared to traditional methods.

These factors make portable laser welding a cost-effective and efficient option for industries seeking to upgrade from conventional technologies.

Why Businesses Prefer Portable Laser Welding

In fast-paced industrial environments, downtime is costly. A laser welding machine portable addresses this challenge by providing rapid setup and execution. Traditional welding methods often require adjustments, fixtures, and consumables, while portable systems minimize these steps.

For manufacturers dealing with large assemblies—such as shipbuilding or heavy machinery—moving components to a stationary welding station is impractical. Portability solves this by bringing the machine to the workpiece. This not only saves time but also improves productivity across the production line.

Environmental and Safety Considerations

Another important factor is sustainability. Portable laser welding consumes less energy compared to traditional arc-based systems, aligning with modern industry goals for energy efficiency. Since it produces minimal smoke, fumes, or spatter, it contributes to a cleaner working environment.

Safety is also enhanced. Operators benefit from reduced exposure to harmful emissions, and the focused nature of the laser beam limits unnecessary heat spread. Proper training ensures that workers can use these systems effectively while following standard safety protocols.

Future Outlook for Portable Laser Welding

The demand for laser welding machine portable technology is expected to grow rapidly. Industries are shifting toward automation, precision manufacturing, and energy efficiency—all areas where portable laser welding excels. Integration with robotics and computer-controlled systems will further improve its accuracy and scalability.

As global markets continue to emphasize lightweight materials and complex designs, the ability to weld efficiently in varied conditions will remain critical. This ensures that portable laser welding machines will remain a key player in industrial innovation.

Choosing the Right Portable Laser Welding Machine

When considering a laser welding machine portable, businesses focus on parameters such as:

-

Power Capacity: Determines penetration depth and speed.

-

Cooling Systems: Essential for maintaining performance during continuous use.

-

Ergonomics: Lightweight and user-friendly designs improve operator efficiency.

-

Compatibility: Ability to weld different types and thicknesses of metals.

-

After-Sales Support: Reliable technical assistance ensures long-term performance.

Careful evaluation ensures that companies invest in a machine that aligns with their production needs.

Training and Workforce Integration

Introducing a new welding method requires training for operators. However, laser welding machine portable systems are designed with user-friendly controls, reducing the learning curve. Training focuses on handling, safety procedures, and material-specific settings.

Once integrated, these machines enhance workforce capabilities by combining human skill with advanced technology. The result is a stronger, more flexible production process.

Final Thoughts

The laser welding machine portable is no longer just an innovation—it has become an essential tool for modern industries. Its ability to provide precision, efficiency, and mobility makes it suitable across automotive, aerospace, electronics, and fabrication sectors. As businesses prioritize speed, sustainability, and quality, portable laser welding offers a practical solution that meets evolving industrial needs. Investing in this technology is not only a step toward improved production but also a strategy for long-term competitiveness in the global market.