In a world constrained by rigid screens and brittle circuits, a quiet revolution is unfolding—one where electronics bend, stretch, and conform to the human form. Flexible electronics, once confined to the realm of science fiction, are now driving innovation across industries, from wearable health monitors to rollable displays and smart textiles. This transformative technology is moving from laboratory curiosity to mainstream manufacturing, heralding a new era of seamless integration between technology and everyday life.

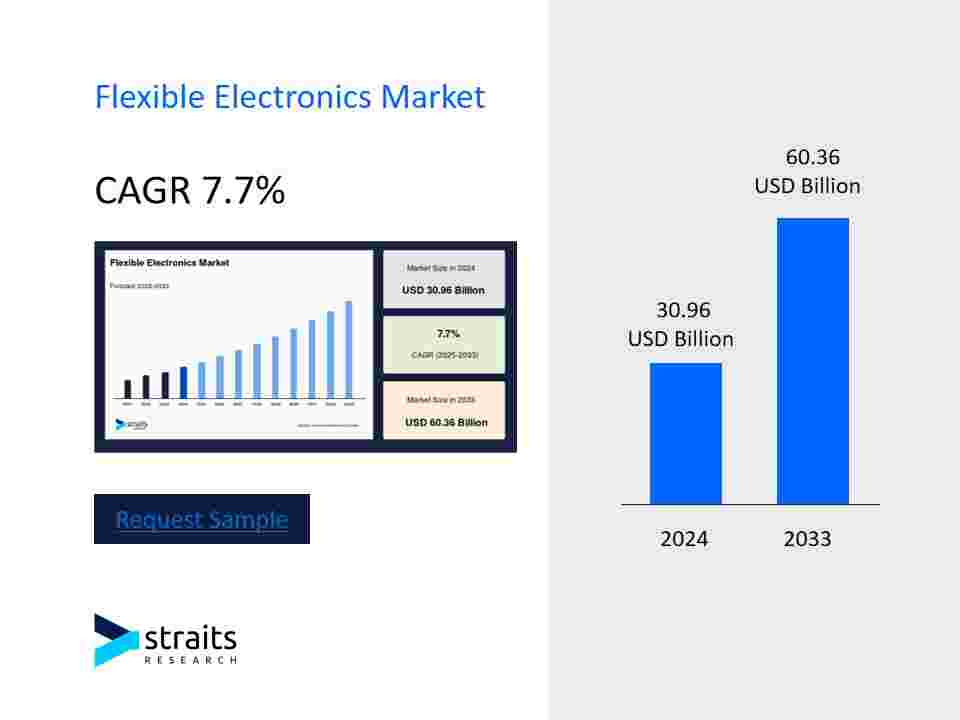

According to Straits Research, the global flexible electronics landscape was valued at USD 30.96 billion in 2024 and is projected to reach from USD 33.34 billion in 2025 to USD 60.36 billion by 2033, growing at a CAGR of 7.7% during the forecast period (2025-2033). This robust growth is fueled by increasing demand for compact, lightweight, and durable electronic devices, advancements in printed electronics, and expanding applications in healthcare, automotive, and consumer electronics.

The field is characterized by intense competition between established electronics giants and specialized innovators. Samsung Electronics (South Korea) remains at the forefront, continuously advancing its flexible OLED display technology for smartphones and exploring applications in foldable tablets. Their recent developments focus on improving durability and reducing production costs to make flexible devices more accessible. LG Display (South Korea) is another key player, investing heavily in scalable manufacturing processes for flexible and transparent displays aimed at automotive and architectural applications.

In the United States, Flex Ltd. (formerly Flextronics) leverages its expertise in semiconductor packaging and printed electronics to develop flexible hybrid systems for medical and industrial applications. Similarly, Palo Alto Research Center (PARC), a Xerox company, continues to pioneer printed electronics techniques, recently announcing a breakthrough in high-speed manufacturing of flexible sensors using roll-to-roll processing.

Recent industry developments highlight the technology's expanding horizons. In a significant advancement, AU Optronics Corp. (Taiwan) unveiled a new 17-inch foldable AMOLED display with ultra-thin glass encapsulation, targeting the laptop and portable display segment. This development addresses the critical challenge of protecting flexible screens while maintaining their pliability. Meanwhile, in Europe, IMEC (Belgium) announced a partnership with a consortium of automotive companies to develop flexible electronic systems for next-generation vehicle interiors, including conformal lighting and integrated health monitoring systems.

From Japan, Semiconductor Energy Laboratory (SEL) continues to innovate in oxide semiconductor materials, crucial for creating flexible, low-power transistors. Their recent patents cover novel architectures for stretchable integrated circuits, pushing the boundaries of how much electronics can deform without losing functionality. In China, companies like BOE Technology are making substantial investments in sixth-generation flexible OLED production lines, aiming to capture significant market share in the display segment.

The trends shaping flexible electronics' future are clear. The integration of functionality is a primary driver, with researchers developing multi-layer systems that combine sensing, energy harvesting, and communication in a single flexible platform. Secondly, sustainability is becoming increasingly important, with efforts focused on developing biodegradable substrates and conductive inks to reduce electronic waste. Finally, the convergence with additive manufacturing is accelerating, enabling custom-shaped electronics produced through 3D printing techniques.

Looking ahead, the technology faces two significant challenges: achieving reliability under repeated mechanical stress and scaling production to meet commercial demands. Solutions are emerging in the form of novel materials like graphene and carbon nanotubes, which offer exceptional mechanical and electrical properties. Companies are also developing innovative testing protocols specifically designed for flexible devices, ensuring they can withstand real-world use conditions.

Summary

Flexible electronics represent a fundamental shift in how we design and interact with technology, enabling applications from wearable health monitors to foldable displays. Driven by advancements in materials science and manufacturing processes, global players are developing increasingly sophisticated and reliable flexible systems. This technology is poised to transform numerous industries by making electronics more integrated, durable, and adaptable to human needs.