In today's competitive construction industry, success is not only measured by project completion but also by the quality of work delivered. Construction Quality Management (CQM) ensures that projects meet client expectations, industry standards, and regulatory requirements, while also promoting safety, efficiency, and long-term durability. This guide explores what construction quality management is, why it matters, and the key practices that can help you achieve excellence in every project.

What Is Construction Quality Management?

Construction Quality Management is a structured process that involves planning, monitoring, and controlling construction activities to ensure that the final output aligns with design specifications, codes, and customer requirements. It goes beyond checking for defects—it integrates preventive measures, continuous improvement, and accountability throughout the project lifecycle.

Why Construction Quality Management Matters

-

Client Satisfaction – High-quality work builds trust and long-term relationships with clients.

-

Safety Compliance – Adhering to quality standards reduces accidents and ensures a safer work environment.

-

Cost Efficiency – Preventing rework and delays saves time, materials, and money.

-

Reputation and Growth – Companies with strong quality management practices earn credibility in the marketplace.

-

Sustainability – Quality management often aligns with sustainable practices, ensuring durability and environmental responsibility.

Core Elements of Construction Quality Management

-

Quality Planning

Setting clear standards, defining responsibilities, and establishing procedures at the project’s start. Quality planning ensures that every stakeholder understands expectations. -

Quality Assurance (QA)

Proactive measures, such as training, process checks, and audits, that prevent mistakes before they occur. QA ensures systems and processes are reliable. -

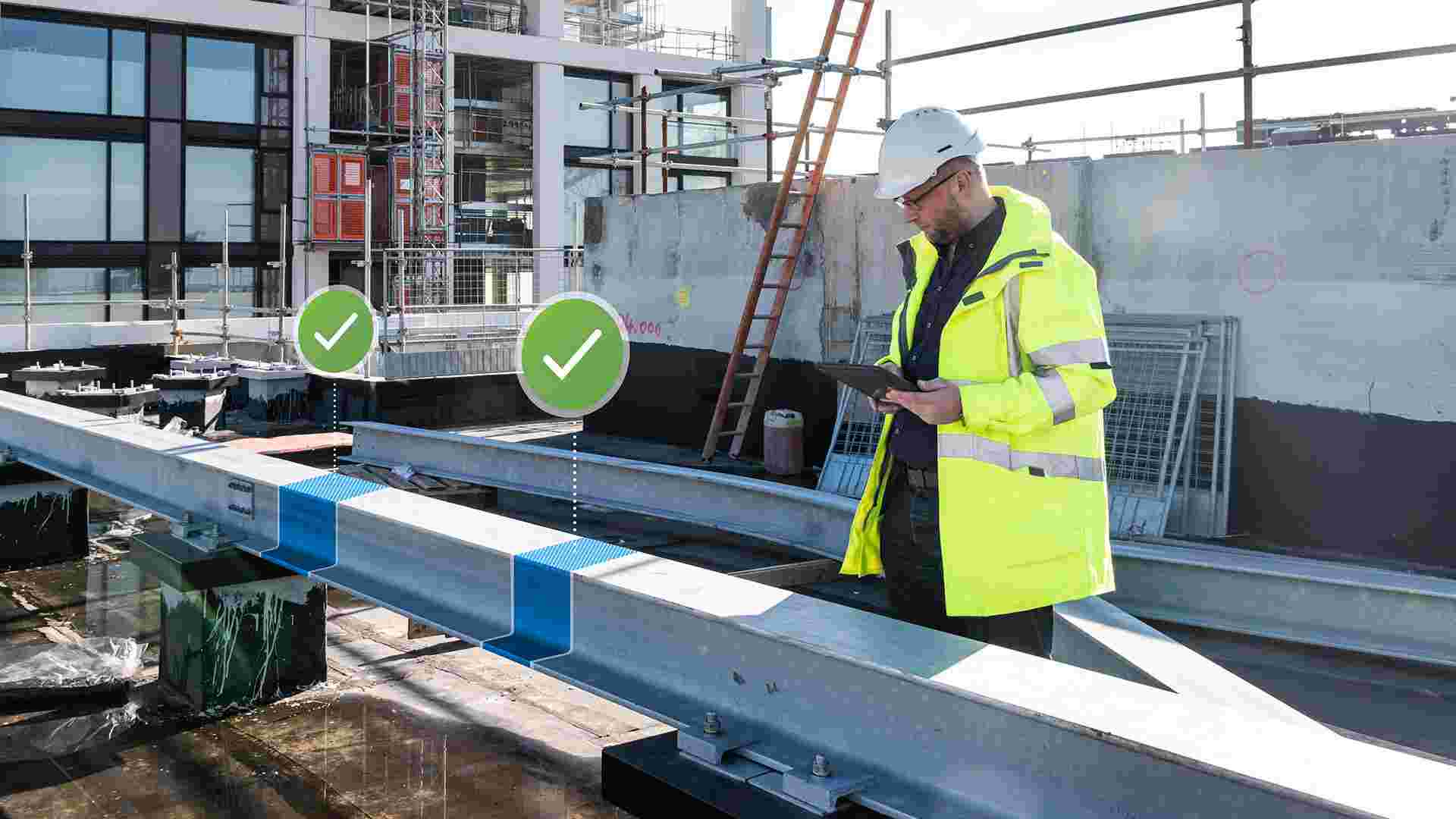

Quality Control (QC)

Inspections, testing, and monitoring conducted during and after construction to ensure the work meets defined standards. -

Continuous Improvement

Using lessons learned from past projects to refine processes and achieve higher performance on future projects.

Best Practices for Construction Quality Management

-

Develop a Comprehensive Quality Plan – Document project-specific quality standards and procedures.

-

Invest in Training – Equip workers and managers with the skills to understand and implement quality measures.

-

Leverage Technology – Use construction management software, drones, and digital inspections to monitor quality in real time.

-

Engage Stakeholders – Foster communication between architects, engineers, contractors, and clients.

-

Conduct Regular Audits – Schedule frequent reviews to catch issues early and minimize rework.

Challenges in Construction Quality Management

Despite its benefits, CQM can face obstacles such as budget constraints, lack of skilled labor, or poor communication among teams. To overcome these challenges, firms should adopt a proactive mindset, invest in training, and implement digital solutions that streamline workflows and improve accountability.

The Future of Construction Quality Management

With the rise of smart technologies, automation, and sustainability goals, quality management is evolving rapidly. Predictive analytics, real-time monitoring, and Building Information Modeling (BIM) are transforming the way companies track and maintain quality, paving the way for safer, more efficient, and more sustainable construction.

Conclusion

Construction Quality Management is not just a process—it's a commitment to excellence. By integrating quality planning, assurance, and control into every stage of a project, companies can deliver superior results, minimize risks, and achieve long-term success. In a world where clients demand reliability and safety, investing in strong quality management practices is no longer optional—it's essential.