Anti-Foaming Agents Market growth driven by increasing adoption in wastewater treatment industries emphasizes the importance of foam-control solutions in maintaining operational efficiency, treatment effectiveness, and equipment longevity. Foam formation during aeration, chemical dosing, and biological treatment can reduce oxygen transfer efficiency, cause overflow, and disrupt treatment processes. Anti-foaming agents prevent foam-related issues, ensuring smooth operations, improved treatment performance, and consistent effluent quality. With growing global urbanization, industrial wastewater generation, and stringent environmental regulations, wastewater treatment facilities are increasingly relying on effective defoamers to optimize operations and maintain compliance.

Foam Challenges in Wastewater Treatment

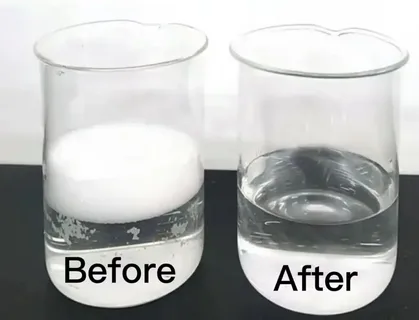

Foam is a common problem in wastewater treatment due to surfactants, aeration, biological activity, and chemical additives. Excess foam can lead to:

-

Reduced oxygen transfer efficiency in aeration tanks

-

Overflow in clarifiers and aeration basins

-

Operational delays and increased maintenance requirements

-

Compromised effluent quality and regulatory non-compliance

Anti-foaming agents help mitigate these challenges, ensuring consistent treatment performance, process stability, and regulatory compliance. Foam control is particularly critical in activated sludge systems, aerated lagoons, and industrial wastewater facilities where uncontrolled foam can hinder treatment efficiency.

Applications in Wastewater Treatment

Municipal Wastewater: Foam suppression ensures efficient aeration, clarifier performance, and compliance with effluent discharge standards.

Industrial Wastewater: Anti-foaming agents prevent foam formation in chemical, food, beverage, and pharmaceutical wastewater, ensuring consistent treatment.

Sludge Treatment: Foam control improves dewatering, reduces sludge volume, and minimizes handling challenges.

Aeration Tanks and Biological Reactors: Maintains oxygen transfer efficiency, promoting optimal microbial activity and process stability.

Chemical Dosing Processes: Foam suppression ensures accurate dosing and prevents overflow during chemical treatment.

These applications highlight the critical role of anti-foaming agents in maintaining operational efficiency, treatment effectiveness, and equipment protection in wastewater treatment operations.

Drivers of Market Growth

-

Increasing Wastewater Generation: Rising urbanization and industrial activities drive the need for efficient foam-control solutions.

-

Operational Efficiency: Foam suppression reduces downtime, maintenance, and chemical overuse, improving overall treatment efficiency.

-

Regulatory Compliance: Effective foam management supports adherence to environmental regulations and effluent quality standards.

-

Sustainability Initiatives: Use of eco-friendly defoamers aligns with environmental sustainability and green treatment practices.

These factors collectively contribute to the growth of the anti-foaming agents market within wastewater treatment industries.

Technological Advancements

Recent innovations in anti-foaming agents for wastewater treatment include:

-

Silicone-based defoamers: Highly effective in diverse wastewater matrices, providing rapid and long-lasting foam suppression.

-

Non-silicone and biodegradable alternatives: Environmentally safe solutions suitable for municipal and industrial wastewater treatment.

-

Oil- and water-dispersible formulations: Ensure uniform distribution and efficient foam control in aeration tanks and reactors.

-

Customized formulations: Designed for specific wastewater types, organic load, and treatment conditions to optimize performance.

These advancements help achieve reliable, sustainable, and efficient foam management while maintaining treatment performance and regulatory compliance.

Regional Insights

-

Asia-Pacific: Leading adoption due to rapid urbanization, industrialization, and wastewater infrastructure expansion in China, India, and Southeast Asia.

-

North America: Market growth driven by advanced treatment facilities, stringent regulations, and sustainability focus.

-

Europe: Emphasis on eco-friendly and regulatory-compliant treatment practices encourages adoption.

-

Latin America and Middle East: Growing wastewater treatment projects and industrial expansion present new opportunities.

Challenges

-

Ensuring defoamer compatibility with diverse wastewater characteristics, pH, and chemical composition.

-

Higher costs of specialized, environmentally compliant, and high-performance defoamers.

-

Maintaining efficiency under variable flow rates, aeration conditions, and organic load fluctuations.

Addressing these challenges requires proper formulation selection, monitoring, and continuous process optimization for effective foam control.

Future Outlook

The wastewater treatment sector is expected to drive sustained demand for anti-foaming agents. Increasing wastewater volumes, stricter environmental regulations, and operational efficiency needs will boost adoption. Eco-friendly, high-performance, and application-specific defoamers are projected to dominate market growth. Manufacturers focusing on innovation, sustainability, and reliable performance are likely to capture significant market share.

Conclusion

The anti-foaming agents market is witnessing growth driven by rising adoption in wastewater treatment industries. By enhancing operational efficiency, ensuring treatment effectiveness, and supporting regulatory compliance, foam-control solutions have become essential. Continued innovation, sustainable formulations, and application-specific solutions will define future market expansion.