The tray sealing machines market is witnessing a significant transformation as food manufacturers and packaging companies increasingly adopt automated and semi-automated sealing technologies. These machines are revolutionizing the packaging industry by enhancing productivity, ensuring consistent quality, and reducing operational costs. As demand for ready-to-eat meals, pre-packaged convenience foods, and perishable products rises, the adoption of modern tray sealing solutions has become essential for companies aiming to meet efficiency and hygiene standards.

Market Overview

In 2024, the global tray sealing machines market was valued at approximately USD 1.29 billion and is projected to reach USD 1.64 billion by 2030, registering a compound annual growth rate (CAGR) of 4.3% from 2025 to 2030. The growing need for faster production, better product preservation, and advanced packaging solutions are key factors driving market expansion. Automated and semi-automated tray sealing machines play a pivotal role in addressing these industry demands.

Adoption of Automated Tray Sealing Machines

Automated tray sealing machines are designed to handle large volumes of products with minimal human intervention. These machines are equipped with robotic arms, conveyors, and intelligent control systems, allowing continuous and high-speed operations. The primary advantages of automated systems include:

-

Increased Productivity: Automated machines can handle multiple trays simultaneously, significantly boosting production rates.

-

Consistent Sealing Quality: Advanced sensors and temperature control mechanisms ensure uniform sealing, reducing product spoilage.

-

Reduced Labor Costs: Automation minimizes the need for manual labor, allowing manufacturers to allocate workforce to other operational areas.

-

Real-Time Monitoring: Integration with IoT technology enables real-time monitoring of machine performance, seal integrity, and operational efficiency.

These features make automated tray sealing machines particularly suitable for large-scale food processing and packaging facilities, where high-volume production and stringent hygiene standards are critical.

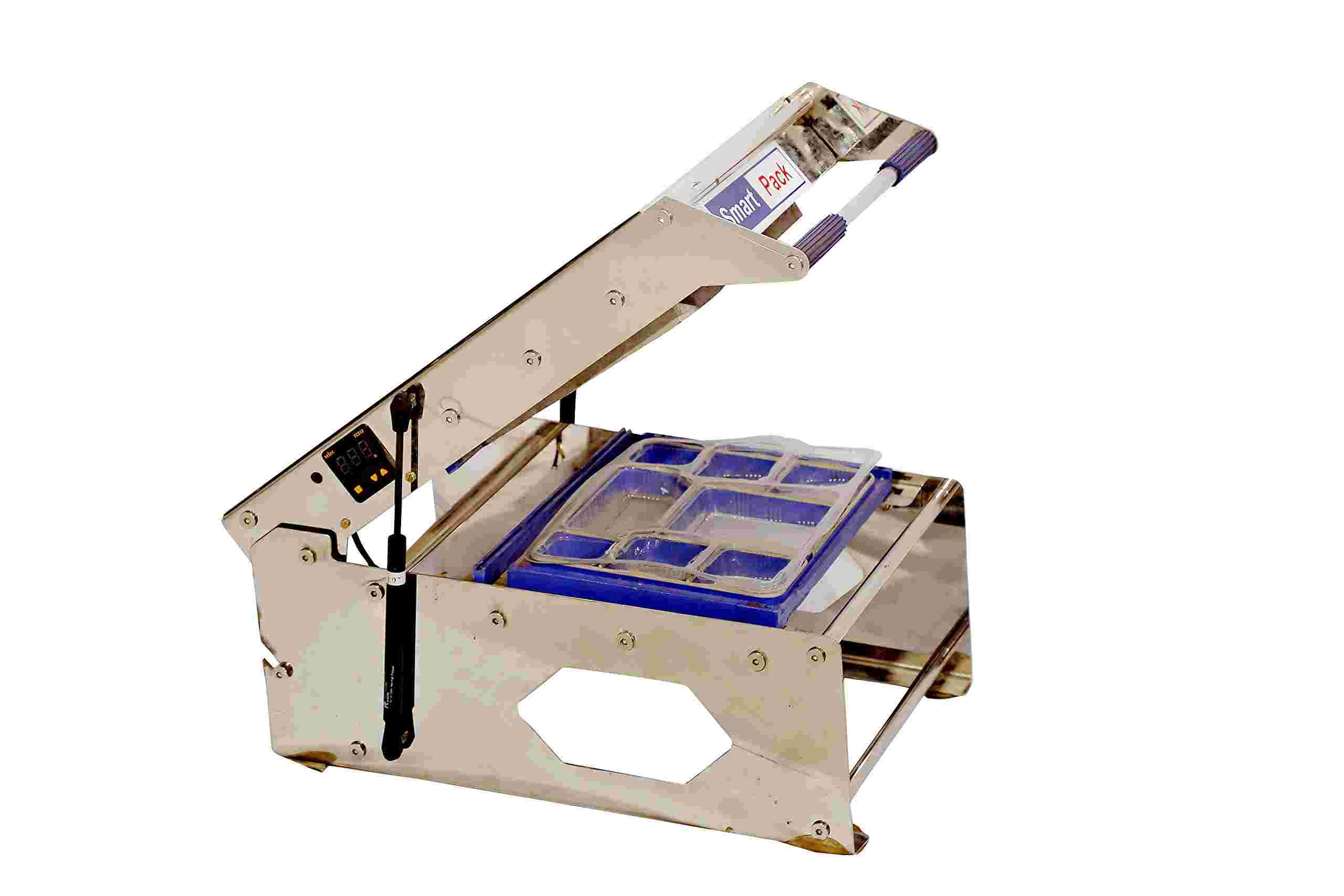

Semi-Automated Tray Sealing Machines

Semi-automated tray sealing machines offer a balance between manual and fully automated operations, making them ideal for small and medium-sized enterprises (SMEs) or niche food production lines. These machines combine human input with automated functions such as tray positioning, sealing, and cutting. Key benefits include:

-

Cost-Effectiveness: Semi-automated machines have lower initial investment costs compared to fully automated systems.

-

Flexibility: They can handle different tray sizes and packaging formats, catering to diverse product lines.

-

Improved Efficiency: Even with partial automation, these machines enhance productivity compared to fully manual operations.

-

Ease of Maintenance: Simpler designs make semi-automated machines easier to maintain, reducing downtime.

Semi-automated machines are particularly popular in regional food processing units and specialty product lines where production volumes are moderate but consistent sealing quality is required.

Technological Advancements Enhancing Market Growth

Modern tray sealing machines are integrating advanced technologies that further improve operational efficiency and sustainability:

-

Smart Sensors: These sensors detect tray positioning and seal integrity, reducing errors and waste.

-

IoT Connectivity: Real-time data collection and analytics optimize maintenance schedules and improve production planning.

-

Energy Efficiency: Machines with energy-saving features reduce power consumption while maintaining high performance.

-

Compatibility with Sustainable Materials: Tray sealing machines now accommodate recyclable, biodegradable, and eco-friendly trays and films, supporting sustainability initiatives.

These innovations are enabling food manufacturers to optimize their packaging processes, enhance product safety, and reduce environmental impact.

Regional Market Insights

Asia Pacific leads the global tray sealing machines market, accounting for 36.8% of the total share in 2024. Rapid urbanization, expanding food processing industries, and increasing disposable incomes are driving demand in countries like China and India.

North America and Europe are also significant markets. In North America, the focus on convenience foods and food safety regulations drives adoption, while Europe emphasizes sustainable packaging solutions. The U.S. market is projected to grow at a CAGR of 3.4% from 2025 to 2030, with semi-automated and automated machines being increasingly utilized to meet operational efficiency goals.

Future Outlook

The tray sealing machines market is poised for continued growth as automated and semi-automated technologies become standard in food packaging operations. Manufacturers are expected to invest in machines that offer higher throughput, greater flexibility, and real-time monitoring capabilities. As consumer demand for packaged foods grows and sustainability becomes a priority, the adoption of smart and efficient tray sealing solutions will remain a key driver for market expansion.