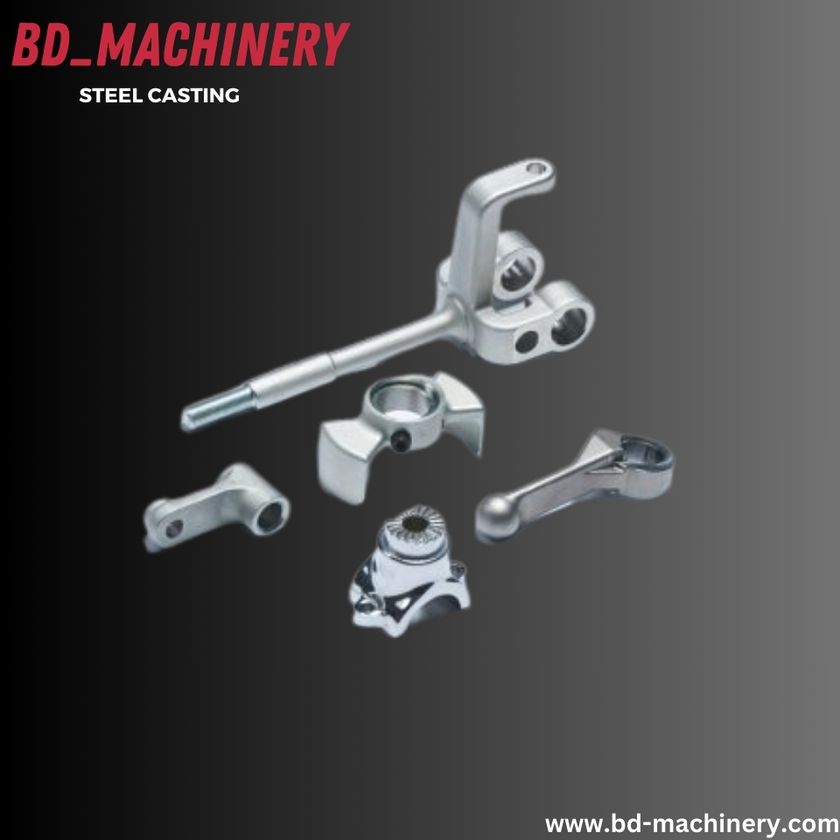

Steel casting is a vital manufacturing process used to create complex metal parts with precise geometries and exceptional mechanical properties. This technique involves pouring molten steel into a mold to produce a desired shape, which is then solidified and finished to meet specific requirements. Steel casting is essential across various industries, including automotive, aerospace, construction, and machinery, due to its ability to produce robust and durable components. This guide provides an in-depth look at the steel casting process, its types, applications, and best practices to ensure high-quality outputs.

Types of Steel Casting

-

Sand Casting

- Process : Molten steel is poured into a sand mold that has been shaped around a pattern of the desired part.

- Advantages : Cost-effective, suitable for large and complex parts.

- Applications : Engine blocks, pump housings, and large machinery components.

-

Investment Casting

- Process : Also known as lost-wax casting, this method involves creating a wax pattern, coating it with a ceramic shell, and then melting the wax away to leave a mold for the steel.

- Advantages : High precision, excellent surface finish, suitable for intricate designs.

- Applications : Turbine blades, medical implants, and small precision components.

-

Die Casting

- Process : Molten steel is injected into a mold cavity under high pressure.

- Advantages : High production rate, good dimensional accuracy, and smooth surface finish.

- Applications : Automotive parts, consumer electronics, and small mechanical parts.

-

Centrifugal Casting

- Process : Molten steel is poured into a rotating mold, which distributes the metal evenly by centrifugal force.

- Advantages : Produces parts with fine grain structure and good mechanical properties.

- Applications : Pipes, rings, and cylinder liners.

Steel Casting Process

-

Pattern Making

- Creating a replica of the part to be cast, which can be made from wood, metal, or plastic.

-

Mold Preparation

- For sand casting, the pattern is placed in sand to create a mold. In investment casting, the wax pattern is coated with a ceramic material to form a shell.

-

Melting and Pouring

- Steel is melted in a furnace and poured into the prepared mold. The temperature and composition of the molten steel are carefully controlled to ensure quality.

-

Cooling and Solidification

- The molten steel cools and solidifies within the mold, forming the desired shape. The cooling rate can affect the grain structure and mechanical properties of the cast steel.

-

Removal and Finishing

- Once solidified, the cast part is removed from the mold. Excess material is trimmed, and the part undergoes various finishing processes such as grinding, heat treatment, and surface coating.

Applications of Steel Casting

Steel casting is used to produce a wide range of critical components to numerous industries:

- Automotive : Engine components, suspension parts, and brake systems.

- Aerospace : Structural parts, landing gear components, and turbine blades.

- Construction : Structural beams, columns, and reinforcements.

- Machinery : Gears, valves, and pumps.

- Medical : Surgical instruments, orthopedic implants, and dental appliances.

Best Practices for Steel Casting

-

Material Selection

- Choose the appropriate steel alloy based on the part's requirements for strength, ductility, and corrosion resistance.

-

Design Considerations

- Optimize the design for manufacturability, considering factors such as mold design, gating systems, and solidification patterns.

-

Quality Control

- Implement rigorous quality control measures, including inspection of raw materials, process monitoring, and non-destructive testing of finished parts.

-

Environmental and Safety Practices

- Adhere to environmental regulations and ensure safe handling of materials and equipment throughout the casting process.

Conclusion

Steel casting is a complex yet essential manufacturing process that enables the production of high-quality metal parts with diverse applications. By understanding the different steel casting methods, adhering to best practices, and maintaining strict quality control, manufacturers can achieve optimal results and meet the demanding standards of various industries.