Hydrogen Generation Market to Reach USD 188.46 Bn by 2025, Driven by Increasing Home Report Details Energy & Power Hydrogen Generation

Hydrogen Generation Market – Powering the Clean Energy Transition

Market Estimation & Definition

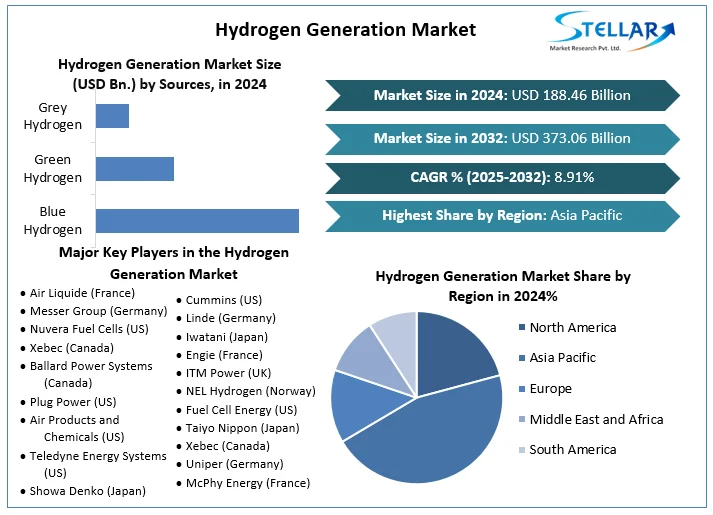

The hydrogen generation market refers to the production of hydrogen gas through various processes such as steam methane reforming (SMR), electrolysis, coal gasification, and renewable-powered methods. Hydrogen plays a pivotal role in decarbonization strategies, serving as a clean fuel and industrial feedstock.

As of 2024, the global hydrogen generation market is valued at USD 160 billion and is projected to reach USD 240 billion by 2030, growing at a CAGR of nearly 7%. Its expansion is fueled by rising investments in clean energy, government decarbonization targets, and growing adoption across mobility, power, and industrial applications.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Hydrogen-Generation-Market/370

Market Growth Drivers & Opportunities

Decarbonization Imperatives: Countries worldwide are integrating hydrogen into net-zero strategies to replace fossil fuels in energy-intensive industries.

Transport Sector Adoption: Fuel cell electric vehicles (FCEVs), trains, and even aircraft are exploring hydrogen as a sustainable alternative.

Industrial Demand: Refineries, chemical plants, and steelmaking industries are adopting hydrogen for reducing carbon emissions.

Electrolyzer Technology Advancements: Declining costs of renewable energy and electrolysis equipment are enhancing green hydrogen feasibility.

Government Incentives: Subsidies, funding programs, and hydrogen roadmaps in regions like the EU, Japan, and the U.S. are driving investments.

Opportunities lie in green hydrogen projects, hydrogen storage solutions, and cross-border hydrogen supply chains.

Emerging Trends Shaping the Future

Shift Toward Green Hydrogen: Renewable-powered electrolysis is set to dominate future hydrogen production.

Hydrogen Hubs: Clusters of hydrogen production, storage, and distribution facilities are emerging globally.

Energy Storage Applications: Hydrogen is being used to store surplus renewable energy for grid stability.

Infrastructure Development: Rapid expansion of hydrogen refueling stations to support FCEVs.

Global Partnerships: Collaborations between energy companies, technology providers, and governments are accelerating commercialization.

Segmentation Analysis

By Source:

• Blue Hydrogen (SMR with carbon capture)

• Green Hydrogen (Electrolysis via renewable power)

• Grey Hydrogen (SMR without carbon capture)

• Others (Coal gasification, biomass gasification)

By Application:

• Power Generation

• Transportation

• Industrial Use (Refining, Chemicals, Steel)

• Energy Storage

By Technology:

• Steam Methane Reforming

• Electrolysis

• Coal Gasification

• Others

By Region:

• North America

• Europe

• Asia-Pacific

• Middle East & Africa

• Latin America

Country-Level Insights

United States: Significant investments through the Inflation Reduction Act, positioning hydrogen as a key decarbonization fuel.

Germany: A leader in green hydrogen, with strong government backing for hydrogen hubs and industrial decarbonization.

Japan & South Korea: Pioneers in hydrogen mobility with national strategies to scale FCEVs and refueling stations.

China: Rapid adoption in heavy-duty transport and large-scale hydrogen projects integrated with renewables.

India: Launch of the National Green Hydrogen Mission to reduce dependence on fossil fuel imports and promote renewable integration.

Competitive Landscape

Key companies driving the hydrogen generation market include:

Air Liquide

Linde plc

Air Products and Chemicals, Inc.

Cummins Inc.

Nel ASA

Plug Power Inc.

Siemens Energy

ITM Power

Engie

Ballard Power Systems

Strategic Approaches: Companies are focusing on scaling electrolyzer manufacturing, forming strategic alliances, and investing in renewable-powered hydrogen plants. Additionally, partnerships with automakers and industrial giants are enabling large-scale adoption.

Press Release Conclusion

The Hydrogen Generation Market is projected to grow from USD 160 billion in 2024 to USD 240 billion by 2030, driven by decarbonization policies, technological advancements, and expanding applications across industries and transport.

With green hydrogen at the forefront of energy transition, investments in electrolyzers, hydrogen hubs, and infrastructure will be critical. Companies that innovate in cost reduction, storage, and large-scale deployment will be positioned as leaders in this transformative market, shaping the future of clean energy worldwide.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]

Hydrogen Generation Market – Powering the Clean Energy Transition

Market Estimation & Definition

The hydrogen generation market refers to the production of hydrogen gas through various processes such as steam methane reforming (SMR), electrolysis, coal gasification, and renewable-powered methods. Hydrogen plays a pivotal role in decarbonization strategies, serving as a clean fuel and industrial feedstock.

As of 2024, the global hydrogen generation market is valued at USD 160 billion and is projected to reach USD 240 billion by 2030, growing at a CAGR of nearly 7%. Its expansion is fueled by rising investments in clean energy, government decarbonization targets, and growing adoption across mobility, power, and industrial applications.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Hydrogen-Generation-Market/370

Market Growth Drivers & Opportunities

Decarbonization Imperatives: Countries worldwide are integrating hydrogen into net-zero strategies to replace fossil fuels in energy-intensive industries.

Transport Sector Adoption: Fuel cell electric vehicles (FCEVs), trains, and even aircraft are exploring hydrogen as a sustainable alternative.

Industrial Demand: Refineries, chemical plants, and steelmaking industries are adopting hydrogen for reducing carbon emissions.

Electrolyzer Technology Advancements: Declining costs of renewable energy and electrolysis equipment are enhancing green hydrogen feasibility.

Government Incentives: Subsidies, funding programs, and hydrogen roadmaps in regions like the EU, Japan, and the U.S. are driving investments.

Opportunities lie in green hydrogen projects, hydrogen storage solutions, and cross-border hydrogen supply chains.

Emerging Trends Shaping the Future

Shift Toward Green Hydrogen: Renewable-powered electrolysis is set to dominate future hydrogen production.

Hydrogen Hubs: Clusters of hydrogen production, storage, and distribution facilities are emerging globally.

Energy Storage Applications: Hydrogen is being used to store surplus renewable energy for grid stability.

Infrastructure Development: Rapid expansion of hydrogen refueling stations to support FCEVs.

Global Partnerships: Collaborations between energy companies, technology providers, and governments are accelerating commercialization.

Segmentation Analysis

By Source:

• Blue Hydrogen (SMR with carbon capture)

• Green Hydrogen (Electrolysis via renewable power)

• Grey Hydrogen (SMR without carbon capture)

• Others (Coal gasification, biomass gasification)

By Application:

• Power Generation

• Transportation

• Industrial Use (Refining, Chemicals, Steel)

• Energy Storage

By Technology:

• Steam Methane Reforming

• Electrolysis

• Coal Gasification

• Others

By Region:

• North America

• Europe

• Asia-Pacific

• Middle East & Africa

• Latin America

Country-Level Insights

United States: Significant investments through the Inflation Reduction Act, positioning hydrogen as a key decarbonization fuel.

Germany: A leader in green hydrogen, with strong government backing for hydrogen hubs and industrial decarbonization.

Japan & South Korea: Pioneers in hydrogen mobility with national strategies to scale FCEVs and refueling stations.

China: Rapid adoption in heavy-duty transport and large-scale hydrogen projects integrated with renewables.

India: Launch of the National Green Hydrogen Mission to reduce dependence on fossil fuel imports and promote renewable integration.

Competitive Landscape

Key companies driving the hydrogen generation market include:

Air Liquide

Linde plc

Air Products and Chemicals, Inc.

Cummins Inc.

Nel ASA

Plug Power Inc.

Siemens Energy

ITM Power

Engie

Ballard Power Systems

Strategic Approaches: Companies are focusing on scaling electrolyzer manufacturing, forming strategic alliances, and investing in renewable-powered hydrogen plants. Additionally, partnerships with automakers and industrial giants are enabling large-scale adoption.

Press Release Conclusion

The Hydrogen Generation Market is projected to grow from USD 160 billion in 2024 to USD 240 billion by 2030, driven by decarbonization policies, technological advancements, and expanding applications across industries and transport.

With green hydrogen at the forefront of energy transition, investments in electrolyzers, hydrogen hubs, and infrastructure will be critical. Companies that innovate in cost reduction, storage, and large-scale deployment will be positioned as leaders in this transformative market, shaping the future of clean energy worldwide.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]

Hydrogen Generation Market to Reach USD 188.46 Bn by 2025, Driven by Increasing Home Report Details Energy & Power Hydrogen Generation

Hydrogen Generation Market – Powering the Clean Energy Transition

Market Estimation & Definition

The hydrogen generation market refers to the production of hydrogen gas through various processes such as steam methane reforming (SMR), electrolysis, coal gasification, and renewable-powered methods. Hydrogen plays a pivotal role in decarbonization strategies, serving as a clean fuel and industrial feedstock.

As of 2024, the global hydrogen generation market is valued at USD 160 billion and is projected to reach USD 240 billion by 2030, growing at a CAGR of nearly 7%. Its expansion is fueled by rising investments in clean energy, government decarbonization targets, and growing adoption across mobility, power, and industrial applications.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Hydrogen-Generation-Market/370

Market Growth Drivers & Opportunities

Decarbonization Imperatives: Countries worldwide are integrating hydrogen into net-zero strategies to replace fossil fuels in energy-intensive industries.

Transport Sector Adoption: Fuel cell electric vehicles (FCEVs), trains, and even aircraft are exploring hydrogen as a sustainable alternative.

Industrial Demand: Refineries, chemical plants, and steelmaking industries are adopting hydrogen for reducing carbon emissions.

Electrolyzer Technology Advancements: Declining costs of renewable energy and electrolysis equipment are enhancing green hydrogen feasibility.

Government Incentives: Subsidies, funding programs, and hydrogen roadmaps in regions like the EU, Japan, and the U.S. are driving investments.

Opportunities lie in green hydrogen projects, hydrogen storage solutions, and cross-border hydrogen supply chains.

Emerging Trends Shaping the Future

Shift Toward Green Hydrogen: Renewable-powered electrolysis is set to dominate future hydrogen production.

Hydrogen Hubs: Clusters of hydrogen production, storage, and distribution facilities are emerging globally.

Energy Storage Applications: Hydrogen is being used to store surplus renewable energy for grid stability.

Infrastructure Development: Rapid expansion of hydrogen refueling stations to support FCEVs.

Global Partnerships: Collaborations between energy companies, technology providers, and governments are accelerating commercialization.

Segmentation Analysis

By Source:

• Blue Hydrogen (SMR with carbon capture)

• Green Hydrogen (Electrolysis via renewable power)

• Grey Hydrogen (SMR without carbon capture)

• Others (Coal gasification, biomass gasification)

By Application:

• Power Generation

• Transportation

• Industrial Use (Refining, Chemicals, Steel)

• Energy Storage

By Technology:

• Steam Methane Reforming

• Electrolysis

• Coal Gasification

• Others

By Region:

• North America

• Europe

• Asia-Pacific

• Middle East & Africa

• Latin America

Country-Level Insights

United States: Significant investments through the Inflation Reduction Act, positioning hydrogen as a key decarbonization fuel.

Germany: A leader in green hydrogen, with strong government backing for hydrogen hubs and industrial decarbonization.

Japan & South Korea: Pioneers in hydrogen mobility with national strategies to scale FCEVs and refueling stations.

China: Rapid adoption in heavy-duty transport and large-scale hydrogen projects integrated with renewables.

India: Launch of the National Green Hydrogen Mission to reduce dependence on fossil fuel imports and promote renewable integration.

Competitive Landscape

Key companies driving the hydrogen generation market include:

Air Liquide

Linde plc

Air Products and Chemicals, Inc.

Cummins Inc.

Nel ASA

Plug Power Inc.

Siemens Energy

ITM Power

Engie

Ballard Power Systems

Strategic Approaches: Companies are focusing on scaling electrolyzer manufacturing, forming strategic alliances, and investing in renewable-powered hydrogen plants. Additionally, partnerships with automakers and industrial giants are enabling large-scale adoption.

Press Release Conclusion

The Hydrogen Generation Market is projected to grow from USD 160 billion in 2024 to USD 240 billion by 2030, driven by decarbonization policies, technological advancements, and expanding applications across industries and transport.

With green hydrogen at the forefront of energy transition, investments in electrolyzers, hydrogen hubs, and infrastructure will be critical. Companies that innovate in cost reduction, storage, and large-scale deployment will be positioned as leaders in this transformative market, shaping the future of clean energy worldwide.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]

0 Bình luận

0 Chia sẻ

330 Lượt xem