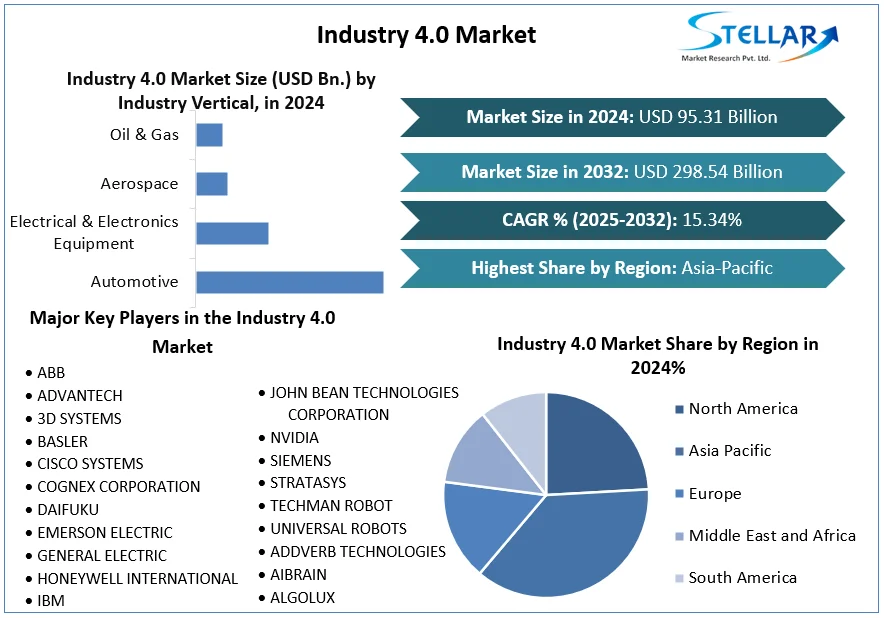

Industry 4.0 Market Size to Grow at a CAGR of 15.34% in the Forecast Period of 2025-2032

Industry 4.0 Market – Driving the Next Industrial Revolution

1. Market Estimation & Definition

The Industry 4.0 market refers to the integration of advanced digital technologies—such as artificial intelligence (AI), Internet of Things (IoT), robotics, big data analytics, augmented reality (AR), virtual reality (VR), and cloud computing—into manufacturing and industrial operations. This digital transformation enables smart factories, predictive maintenance, real-time monitoring, and enhanced supply chain efficiency.

As of 2024, the global Industry 4.0 market is estimated at USD 150 billion and is projected to reach USD 420 billion by 2030, registering a CAGR of nearly 17%. Rapid adoption of automation, increasing investment in digital infrastructure, and the growing demand for connected and efficient manufacturing ecosystems are driving this exponential growth.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Industry-4.0-Market/276

2. Market Growth Drivers & Opportunities

Rising Automation Across Industries: Manufacturers are adopting robotics, smart sensors, and automated systems to increase productivity and reduce human errors.

Government Initiatives & Funding: Policies supporting smart manufacturing, such as Germany’s “Industrie 4.0” program and similar initiatives in the US, China, and Japan, are accelerating adoption.

Efficiency & Cost Reduction: Real-time data analytics and IoT integration improve asset utilization, reduce downtime, and enhance decision-making.

Growing Adoption of Industrial IoT: Connected devices and machines support predictive maintenance and energy-efficient operations.

Opportunities in SMEs: Increasing affordability of cloud-based Industry 4.0 solutions allows small and medium-sized enterprises to adopt digital transformation strategies.

3. What Lies Ahead: Emerging Trends Shaping the Future

AI-Driven Manufacturing: Artificial intelligence and machine learning will be central to predictive analytics, quality assurance, and autonomous operations.

5G Connectivity: High-speed, low-latency 5G networks will enhance real-time industrial automation and remote monitoring.

Cybersecurity Focus: With the rise of connected systems, investment in robust cybersecurity solutions will become a priority.

Digital Twins: Virtual replicas of physical assets will improve product design, testing, and operational efficiency.

Sustainability Integration: Green manufacturing practices, energy-efficient operations, and carbon-neutral production will be integral to Industry 4.0 strategies.

4. Segmentation Analysis

By Technology:

• Industrial IoT

• Artificial Intelligence (AI) & Machine Learning

• Robotics & Automation

• Augmented & Virtual Reality (AR/VR)

• Big Data & Analytics

• Cloud Computing

• Cybersecurity

By Application:

• Smart Factories

• Predictive Maintenance

• Supply Chain Optimization

• Energy Management

• Quality Control

• Workforce Training & Safety

By End-User Industry:

• Manufacturing (automotive, electronics, aerospace)

• Energy & Utilities

• Healthcare

• Logistics & Transportation

• Consumer Goods

5. Country-Level Analysis

United States: Strong adoption of AI, IoT, and robotics, supported by large-scale investments in digital transformation.

Germany: A global leader in Industry 4.0 initiatives, driven by advanced manufacturing and government-backed programs.

China: Rapid industrial automation and government-backed smart manufacturing projects contribute to high growth.

Japan: Advanced robotics and automation technologies position Japan as a key player in Industry 4.0 solutions.

India: Emerging market potential with growing investments in smart factories and industrial digitalization.

6. Competitive Landscape

Key players in the Industry 4.0 market include:

Siemens AG

General Electric (GE)

ABB Ltd.

Honeywell International Inc.

Rockwell Automation Inc.

Schneider Electric SE

IBM Corporation

Bosch Rexroth AG

Competitive Strategies: Companies focus on mergers & acquisitions, R&D investments, partnerships with cloud providers, and scaling digital platforms. Emphasis on AI, cybersecurity, and sustainability-based solutions differentiates leading players in this evolving market.

7. Press Release Conclusion

The Industry 4.0 Market is entering a transformative phase, projected to grow from USD 150 billion in 2024 to USD 420 billion by 2030, fueled by automation, AI, IoT, and digital integration across industries.

Businesses investing in smart factories, connected ecosystems, and sustainable manufacturing practices will be at the forefront of this revolution. With strong government backing, rapid technological advances, and increasing affordability of digital solutions, Industry 4.0 is reshaping global manufacturing, supply chains, and industrial processes, setting the foundation for the future of intelligent, data-driven economies.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]

Industry 4.0 Market – Driving the Next Industrial Revolution

1. Market Estimation & Definition

The Industry 4.0 market refers to the integration of advanced digital technologies—such as artificial intelligence (AI), Internet of Things (IoT), robotics, big data analytics, augmented reality (AR), virtual reality (VR), and cloud computing—into manufacturing and industrial operations. This digital transformation enables smart factories, predictive maintenance, real-time monitoring, and enhanced supply chain efficiency.

As of 2024, the global Industry 4.0 market is estimated at USD 150 billion and is projected to reach USD 420 billion by 2030, registering a CAGR of nearly 17%. Rapid adoption of automation, increasing investment in digital infrastructure, and the growing demand for connected and efficient manufacturing ecosystems are driving this exponential growth.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Industry-4.0-Market/276

2. Market Growth Drivers & Opportunities

Rising Automation Across Industries: Manufacturers are adopting robotics, smart sensors, and automated systems to increase productivity and reduce human errors.

Government Initiatives & Funding: Policies supporting smart manufacturing, such as Germany’s “Industrie 4.0” program and similar initiatives in the US, China, and Japan, are accelerating adoption.

Efficiency & Cost Reduction: Real-time data analytics and IoT integration improve asset utilization, reduce downtime, and enhance decision-making.

Growing Adoption of Industrial IoT: Connected devices and machines support predictive maintenance and energy-efficient operations.

Opportunities in SMEs: Increasing affordability of cloud-based Industry 4.0 solutions allows small and medium-sized enterprises to adopt digital transformation strategies.

3. What Lies Ahead: Emerging Trends Shaping the Future

AI-Driven Manufacturing: Artificial intelligence and machine learning will be central to predictive analytics, quality assurance, and autonomous operations.

5G Connectivity: High-speed, low-latency 5G networks will enhance real-time industrial automation and remote monitoring.

Cybersecurity Focus: With the rise of connected systems, investment in robust cybersecurity solutions will become a priority.

Digital Twins: Virtual replicas of physical assets will improve product design, testing, and operational efficiency.

Sustainability Integration: Green manufacturing practices, energy-efficient operations, and carbon-neutral production will be integral to Industry 4.0 strategies.

4. Segmentation Analysis

By Technology:

• Industrial IoT

• Artificial Intelligence (AI) & Machine Learning

• Robotics & Automation

• Augmented & Virtual Reality (AR/VR)

• Big Data & Analytics

• Cloud Computing

• Cybersecurity

By Application:

• Smart Factories

• Predictive Maintenance

• Supply Chain Optimization

• Energy Management

• Quality Control

• Workforce Training & Safety

By End-User Industry:

• Manufacturing (automotive, electronics, aerospace)

• Energy & Utilities

• Healthcare

• Logistics & Transportation

• Consumer Goods

5. Country-Level Analysis

United States: Strong adoption of AI, IoT, and robotics, supported by large-scale investments in digital transformation.

Germany: A global leader in Industry 4.0 initiatives, driven by advanced manufacturing and government-backed programs.

China: Rapid industrial automation and government-backed smart manufacturing projects contribute to high growth.

Japan: Advanced robotics and automation technologies position Japan as a key player in Industry 4.0 solutions.

India: Emerging market potential with growing investments in smart factories and industrial digitalization.

6. Competitive Landscape

Key players in the Industry 4.0 market include:

Siemens AG

General Electric (GE)

ABB Ltd.

Honeywell International Inc.

Rockwell Automation Inc.

Schneider Electric SE

IBM Corporation

Bosch Rexroth AG

Competitive Strategies: Companies focus on mergers & acquisitions, R&D investments, partnerships with cloud providers, and scaling digital platforms. Emphasis on AI, cybersecurity, and sustainability-based solutions differentiates leading players in this evolving market.

7. Press Release Conclusion

The Industry 4.0 Market is entering a transformative phase, projected to grow from USD 150 billion in 2024 to USD 420 billion by 2030, fueled by automation, AI, IoT, and digital integration across industries.

Businesses investing in smart factories, connected ecosystems, and sustainable manufacturing practices will be at the forefront of this revolution. With strong government backing, rapid technological advances, and increasing affordability of digital solutions, Industry 4.0 is reshaping global manufacturing, supply chains, and industrial processes, setting the foundation for the future of intelligent, data-driven economies.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]

Industry 4.0 Market Size to Grow at a CAGR of 15.34% in the Forecast Period of 2025-2032

Industry 4.0 Market – Driving the Next Industrial Revolution

1. Market Estimation & Definition

The Industry 4.0 market refers to the integration of advanced digital technologies—such as artificial intelligence (AI), Internet of Things (IoT), robotics, big data analytics, augmented reality (AR), virtual reality (VR), and cloud computing—into manufacturing and industrial operations. This digital transformation enables smart factories, predictive maintenance, real-time monitoring, and enhanced supply chain efficiency.

As of 2024, the global Industry 4.0 market is estimated at USD 150 billion and is projected to reach USD 420 billion by 2030, registering a CAGR of nearly 17%. Rapid adoption of automation, increasing investment in digital infrastructure, and the growing demand for connected and efficient manufacturing ecosystems are driving this exponential growth.

Request Free Sample Report:https://www.stellarmr.com/report/req_sample/Industry-4.0-Market/276

2. Market Growth Drivers & Opportunities

Rising Automation Across Industries: Manufacturers are adopting robotics, smart sensors, and automated systems to increase productivity and reduce human errors.

Government Initiatives & Funding: Policies supporting smart manufacturing, such as Germany’s “Industrie 4.0” program and similar initiatives in the US, China, and Japan, are accelerating adoption.

Efficiency & Cost Reduction: Real-time data analytics and IoT integration improve asset utilization, reduce downtime, and enhance decision-making.

Growing Adoption of Industrial IoT: Connected devices and machines support predictive maintenance and energy-efficient operations.

Opportunities in SMEs: Increasing affordability of cloud-based Industry 4.0 solutions allows small and medium-sized enterprises to adopt digital transformation strategies.

3. What Lies Ahead: Emerging Trends Shaping the Future

AI-Driven Manufacturing: Artificial intelligence and machine learning will be central to predictive analytics, quality assurance, and autonomous operations.

5G Connectivity: High-speed, low-latency 5G networks will enhance real-time industrial automation and remote monitoring.

Cybersecurity Focus: With the rise of connected systems, investment in robust cybersecurity solutions will become a priority.

Digital Twins: Virtual replicas of physical assets will improve product design, testing, and operational efficiency.

Sustainability Integration: Green manufacturing practices, energy-efficient operations, and carbon-neutral production will be integral to Industry 4.0 strategies.

4. Segmentation Analysis

By Technology:

• Industrial IoT

• Artificial Intelligence (AI) & Machine Learning

• Robotics & Automation

• Augmented & Virtual Reality (AR/VR)

• Big Data & Analytics

• Cloud Computing

• Cybersecurity

By Application:

• Smart Factories

• Predictive Maintenance

• Supply Chain Optimization

• Energy Management

• Quality Control

• Workforce Training & Safety

By End-User Industry:

• Manufacturing (automotive, electronics, aerospace)

• Energy & Utilities

• Healthcare

• Logistics & Transportation

• Consumer Goods

5. Country-Level Analysis

United States: Strong adoption of AI, IoT, and robotics, supported by large-scale investments in digital transformation.

Germany: A global leader in Industry 4.0 initiatives, driven by advanced manufacturing and government-backed programs.

China: Rapid industrial automation and government-backed smart manufacturing projects contribute to high growth.

Japan: Advanced robotics and automation technologies position Japan as a key player in Industry 4.0 solutions.

India: Emerging market potential with growing investments in smart factories and industrial digitalization.

6. Competitive Landscape

Key players in the Industry 4.0 market include:

Siemens AG

General Electric (GE)

ABB Ltd.

Honeywell International Inc.

Rockwell Automation Inc.

Schneider Electric SE

IBM Corporation

Bosch Rexroth AG

Competitive Strategies: Companies focus on mergers & acquisitions, R&D investments, partnerships with cloud providers, and scaling digital platforms. Emphasis on AI, cybersecurity, and sustainability-based solutions differentiates leading players in this evolving market.

7. Press Release Conclusion

The Industry 4.0 Market is entering a transformative phase, projected to grow from USD 150 billion in 2024 to USD 420 billion by 2030, fueled by automation, AI, IoT, and digital integration across industries.

Businesses investing in smart factories, connected ecosystems, and sustainable manufacturing practices will be at the forefront of this revolution. With strong government backing, rapid technological advances, and increasing affordability of digital solutions, Industry 4.0 is reshaping global manufacturing, supply chains, and industrial processes, setting the foundation for the future of intelligent, data-driven economies.

About us

Phase 3,Navale IT Zone, S.No. 51/2A/2,

Office No. 202, 2nd floor,

Near, Navale Brg,Narhe,

Pune, Maharashtra 411041

[email protected]

0 Bình luận

0 Chia sẻ

630 Lượt xem