The molds we have come into contact with before are relatively thick in terms of thickness. For some items, thick molds are relatively better, but some molds are indeed as thin as possible. Compared with the basic case, it needs to be thin while being sturdy, like a notebook. If it is too thick, not only will the weight increase, but the aesthetics will not be particularly good. So at this time thin wall plastic mold appeared.

Thin wall plastic mold has good fluidity and must have a large flow length. It also has high impact strength, high heat distortion temperature, and good dimensional stability. Also, the heat resistance, flame retardancy, mechanical assemblability, and appearance quality of the material must be investigated. At present, the widely used materials for thin-wall injection molding include polycarbonate (PC), acrylonitrile-butadiene-styrene (ABS), and PC/ABS blends.

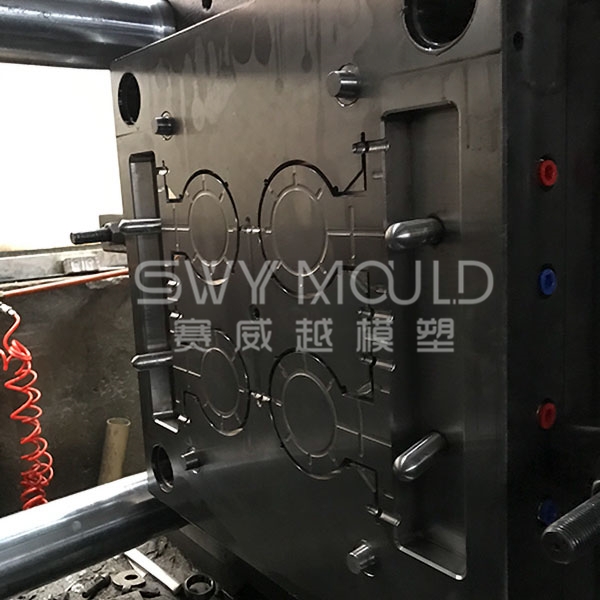

As for plastic pipe fitting injection mould , if it is only thin, it is not enough. The first condition for many pipe fittings is firmness and not the thickness of the mould.